444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2750

Market Overview

Fluoroelastomers, commonly known as FKM (fluorocarbon rubber), are a type of synthetic rubber that exhibit excellent resistance to heat, chemicals, and oil. APAC, short for the Asia-Pacific region, is witnessing significant growth in the fluoroelastomer market. The increasing demand for fluoroelastomers in various end-use industries, such as automotive, aerospace, chemical processing, and oil and gas, is driving the market growth in the APAC region.

Meaning

Fluoroelastomers are a specialized type of synthetic rubber that possess exceptional resistance to high temperatures, chemicals, and oils. These elastomers are primarily composed of fluorine, carbon, and hydrogen atoms, which provide them with unique properties. Due to their outstanding heat resistance and chemical inertness, fluoroelastomers find extensive applications in industries where exposure to harsh environments is common.

Executive Summary

The APAC fluoroelastomer market is experiencing steady growth due to the rising demand from various industries in the region. Fluoroelastomers offer excellent resistance to heat, chemicals, and oils, making them ideal for use in critical applications. The market is driven by factors such as increasing industrialization, expanding automotive and aerospace sectors, and stringent regulations pertaining to safety and environmental standards. However, the market also faces challenges such as high raw material costs and the availability of alternative materials. Despite these obstacles, the APAC fluoroelastomer market presents lucrative opportunities for industry participants.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

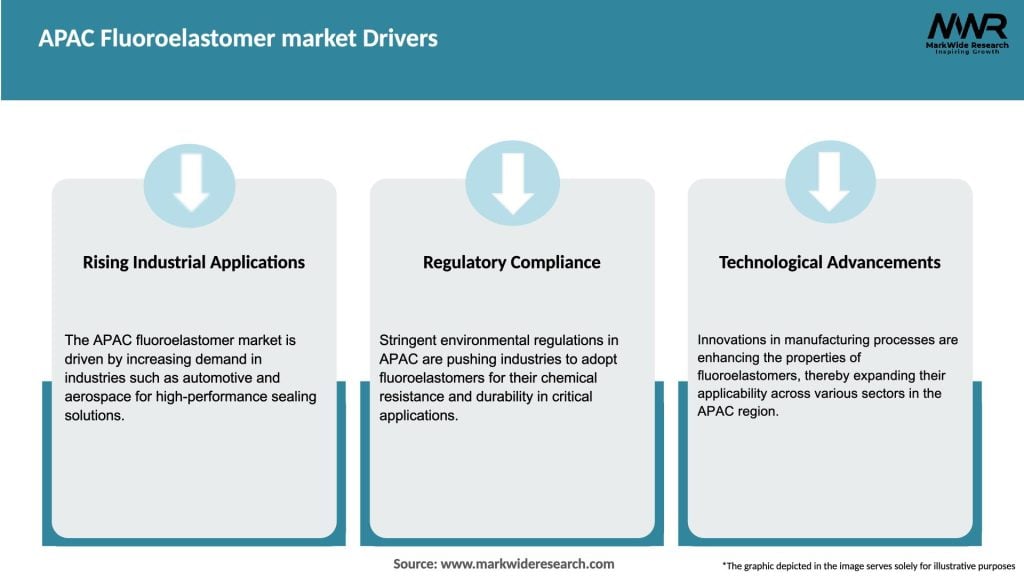

The APAC fluoroelastomer market is driven by several dynamic factors. The region’s rapid industrialization, particularly in countries like China and India, creates a strong demand for fluoroelastomers across various industries. The automotive, aerospace, chemical processing, and oil and gas sectors heavily rely on fluoroelastomers due to their exceptional properties.

The market dynamics are also influenced by regulatory standards and environmental concerns. Stringent regulations regarding safety, emissions, and chemical exposure push industries to adopt fluoroelastomers to meet compliance requirements.

Moreover, advancements in manufacturing processes and the development of new grades of fluoroelastomers contribute to market growth. Continuous research and development efforts focus on enhancing the performance and cost-effectiveness of fluoroelastomers, providing a competitive edge to manufacturers.

The market dynamics are further impacted by the availability of alternative materials. While fluoroelastomers offer superior properties, the higher cost compared to alternatives like silicone and nitrile rubber can lead to substitution in certain applications.

Overall, the APAC fluoroelastomer market is driven by a combination of industrial growth, regulatory requirements, technological advancements, and the need for superior performance in demanding applications.

Regional Analysis

The APAC fluoroelastomer market can be divided into several key regions, including China, India, Japan, South Korea, and Southeast Asian countries. China dominates the regional market due to its robust manufacturing sector, growing automotive industry, and increasing infrastructure development. The country’s large population and rising disposable income also contribute to the demand for automotive and consumer goods, further propelling the fluoroelastomer market.

India is another significant market in the region, driven by its expanding automotive and chemical processing industries. The country’s focus on renewable energy and sustainable solutions presents opportunities for fluoroelastomers in the solar and wind energy sectors.

Japan, known for its technological advancements, has a well-established market for fluoroelastomers. The country’s automotive and electronics industries demand high-performance elastomers for critical applications, ensuring a steady market growth.

South Korea, with its thriving automotive and electronics sectors, is a key consumer of fluoroelastomers. The country’s strong focus on innovation and technological advancements supports the demand for high-quality elastomers.

Southeast Asian countries, including Thailand, Indonesia, and Vietnam, are witnessing rapid industrialization and infrastructural development. The flourishing automotive, chemical, and oil and gas sectors in these countries create a significant demand for fluoroelastomers.

The regional analysis highlights the diverse market landscape in APAC, with each country offering unique growth opportunities based on its industrial and economic dynamics.

Competitive Landscape

Leading Companies in APAC Fluoroelastomer Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

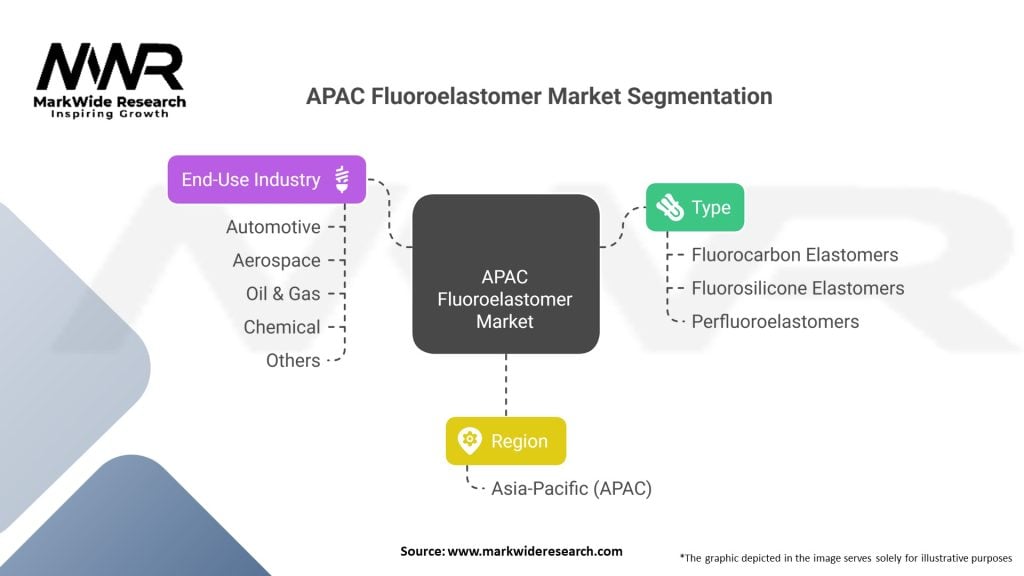

Segmentation

The APAC fluoroelastomer market can be segmented based on:

Segmenting the market allows for a detailed analysis of each segment’s growth, market size, and opportunities. This information helps stakeholders understand the specific demands and requirements of various industries and tailor their strategies accordingly.

Category-wise Insights

Category-wise insights highlight the specific applications and benefits of fluoroelastomers in different industries, emphasizing their versatility and importance in critical sectors.

Key Benefits for Industry Participants and Stakeholders

The key benefits offered by fluoroelastomers to industry participants and stakeholders underline their value and importance across multiple sectors.

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

The SWOT analysis provides a comprehensive understanding of the fluoroelastomer market by evaluating its strengths, weaknesses, opportunities, and threats. This analysis assists industry participants and stakeholders in formulating effective strategies to capitalize on market opportunities and overcome challenges.

Market Key Trends

These key trends reflect the evolving market landscape and the industry’s response to emerging opportunities and challenges.

Covid-19 Impact

The APAC fluoroelastomer market, like many other industries, experienced the impact of the Covid-19 pandemic. The pandemic caused disruptions in the global supply chain, leading to raw material shortages and delayed shipments. Manufacturing operations were affected due to lockdowns and restrictions, resulting in decreased production and demand.

The automotive and aerospace sectors, major consumers of fluoroelastomers, witnessed a significant decline in demand during the pandemic. The closure of manufacturing facilities, reduced consumer spending, and travel restrictions affected these industries’ production and sales.

However, the healthcare sector’s demand for fluoroelastomers remained relatively stable, driven by the need for medical devices and equipment. The pharmaceutical industry also continued to require fluoroelastomers for drug delivery systems and packaging.

As the APAC region gradually recovers from the pandemic, the fluoroelastomer market is expected to rebound. The resumption of industrial activities, economic revival, and government initiatives to boost manufacturing and infrastructure development will contribute to market growth.

Key Industry Developments

Analyst Suggestions

Future Outlook

The APAC fluoroelastomer market is poised for significant growth in the coming years. Factors such as industrialization, expanding automotive and aerospace sectors, and increasing awareness about the benefits of fluoroelastomers will drive market expansion.

The growing focus on sustainability and eco-friendly solutions presents opportunities for manufacturers to develop innovative and environmentally conscious fluoroelastomers. Technological advancements, product diversification, and strategic collaborations will further propel market growth.

However, challenges such as raw material costs, availability of alternatives, and the need for customer education require attention. Manufacturers need to address these challenges through cost optimization, product differentiation, and effective marketing strategies.

Conclusion

In conclusion, the APAC fluoroelastomer market is witnessing steady growth and offers immense opportunities for industry participants. Fluoroelastomers, with their exceptional resistance to heat, chemicals, and oils, cater to the demanding requirements of various industries such as automotive, aerospace, chemical processing, oil and gas, and more. The market is driven by factors such as increasing industrialization, expanding sectors like automotive and aerospace, and the need for compliance with safety and environmental regulations.

While the market presents significant growth prospects, it also faces certain challenges. The high cost of raw materials, availability of alternative materials, and limited awareness among end-users pose hurdles for market growth. However, innovative solutions, advancements in manufacturing processes, and collaborations within the industry can help overcome these challenges.

Overall, the APAC fluoroelastomer market presents a promising landscape for industry players, offering a wide range of applications, growing industries, and the need for high-performance elastomers. With strategic planning, innovation, and a customer-centric approach, companies can thrive in this dynamic market and contribute to its growth and development.

What is Fluoroelastomer?

Fluoroelastomer is a type of synthetic rubber that is highly resistant to heat, chemicals, and oil. It is commonly used in applications such as seals, gaskets, and hoses in various industries including automotive and aerospace.

What are the key players in the APAC Fluoroelastomer market?

Key players in the APAC Fluoroelastomer market include companies like DuPont, 3M, and Daikin Industries, which are known for their innovative products and extensive market reach, among others.

What are the growth factors driving the APAC Fluoroelastomer market?

The growth of the APAC Fluoroelastomer market is driven by increasing demand from the automotive and electronics sectors, as well as the rising need for high-performance materials in industrial applications.

What challenges does the APAC Fluoroelastomer market face?

The APAC Fluoroelastomer market faces challenges such as high production costs and environmental regulations regarding the use of certain chemicals in manufacturing processes.

What opportunities exist in the APAC Fluoroelastomer market?

Opportunities in the APAC Fluoroelastomer market include the development of new formulations for specialized applications and the expansion of production capacities to meet growing demand in emerging economies.

What trends are shaping the APAC Fluoroelastomer market?

Trends in the APAC Fluoroelastomer market include the increasing adoption of sustainable materials and innovations in manufacturing processes that enhance product performance and reduce environmental impact.

APAC Fluoroelastomer Market

| Segmentation | Details |

|---|---|

| Type | Fluorocarbon Elastomers, Fluorosilicone Elastomers, Perfluoroelastomers |

| End-Use Industry | Automotive, Aerospace, Oil & Gas, Chemical, Others |

| Region | Asia-Pacific (APAC) |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in APAC Fluoroelastomer Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at