444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

The Algeria container glass market represents a dynamic and evolving segment within the North African packaging industry, characterized by robust growth potential and increasing industrial sophistication. This market encompasses the production, distribution, and utilization of glass containers across various sectors including food and beverages, pharmaceuticals, cosmetics, and chemicals. Algeria’s strategic position in the Mediterranean region, combined with its growing manufacturing base and expanding consumer market, positions the container glass industry as a critical component of the nation’s industrial development strategy.

Market dynamics in Algeria’s container glass sector are influenced by several key factors including government industrialization initiatives, foreign investment policies, and the country’s efforts to reduce dependency on imports. The industry benefits from abundant natural resources, particularly silica sand deposits, which serve as primary raw materials for glass manufacturing. Local production capacity has been expanding steadily, with growth rates reaching approximately 8.5% annually over recent years, driven by both domestic demand and export opportunities to neighboring African markets.

Industrial infrastructure development has accelerated significantly, with new manufacturing facilities and technology upgrades enhancing production capabilities. The market demonstrates strong potential for continued expansion, supported by Algeria’s young demographic profile and increasing urbanization rates of approximately 73% of the population. Sustainability initiatives and circular economy principles are gaining traction, with glass recycling programs showing promising adoption rates of around 35% in urban areas.

The Algeria container glass market refers to the comprehensive ecosystem encompassing the manufacturing, processing, distribution, and end-use applications of glass packaging containers within Algeria’s domestic and export-oriented economy. This market includes various glass container types such as bottles, jars, vials, and specialty containers designed for specific industrial applications across multiple sectors.

Container glass manufacturing involves the transformation of raw materials including silica sand, soda ash, limestone, and recycled glass cullet into finished packaging products through high-temperature melting and forming processes. The market encompasses both primary production facilities and secondary processing operations that add value through decoration, labeling, and specialized finishing techniques.

Market scope extends beyond traditional packaging applications to include specialized containers for pharmaceuticals, laboratory equipment, and industrial chemicals. The definition also encompasses the supporting infrastructure including raw material suppliers, equipment manufacturers, logistics providers, and end-user industries that collectively form Algeria’s container glass value chain.

Algeria’s container glass market demonstrates significant growth momentum driven by expanding domestic consumption, industrial diversification, and strategic government initiatives aimed at reducing import dependency. The market benefits from favorable raw material availability, growing manufacturing capabilities, and increasing demand from key end-user sectors including food and beverages, pharmaceuticals, and cosmetics.

Key market drivers include rapid urbanization, rising disposable incomes, and changing consumer preferences toward premium packaging solutions. The beverage sector represents the largest application segment, accounting for approximately 55% of total container glass demand, followed by food packaging and pharmaceutical applications. Manufacturing capacity has expanded substantially with new production facilities incorporating advanced technology and automation systems.

Investment flows from both domestic and international sources have accelerated market development, with particular emphasis on technology transfer and skills development. The market shows strong potential for export growth, leveraging Algeria’s strategic location and competitive production costs. Sustainability trends are increasingly influencing market dynamics, with recycling initiatives and eco-friendly production processes gaining prominence among manufacturers and consumers alike.

Strategic market positioning reveals Algeria’s container glass industry as an emerging player in the North African and Mediterranean regions, with significant competitive advantages in raw material access and production costs. The following insights highlight critical market characteristics:

Economic diversification initiatives represent the primary catalyst driving Algeria’s container glass market expansion. The government’s strategic focus on reducing hydrocarbon dependency has led to substantial investments in manufacturing sectors, including glass production. Industrial development policies provide incentives for both domestic and foreign investors, creating favorable conditions for market growth and technology transfer.

Demographic trends significantly influence market demand patterns, with Algeria’s young population and increasing urbanization driving consumption of packaged goods. Rising disposable incomes and changing lifestyle preferences contribute to growing demand for premium packaging solutions across food, beverage, and personal care sectors. Consumer awareness regarding product quality and safety has increased preference for glass packaging due to its inert properties and recyclability.

Infrastructure development projects across Algeria have improved transportation networks, energy supply, and industrial zones, creating more favorable operating conditions for container glass manufacturers. Regional trade agreements and export promotion policies facilitate market access to neighboring countries, expanding potential customer bases. Sustainability regulations and environmental consciousness are driving demand for recyclable packaging materials, positioning glass containers favorably against alternative packaging solutions.

Capital intensity requirements pose significant challenges for new market entrants and expansion projects within Algeria’s container glass industry. High initial investments in furnace technology, production equipment, and quality control systems create substantial barriers to entry. Energy costs represent a major operational expense, with glass manufacturing requiring intensive energy consumption for melting and forming processes.

Technical expertise limitations constrain rapid market development, as specialized knowledge in glass chemistry, furnace operations, and quality control requires extensive training and experience. Import dependency for certain raw materials and specialized equipment creates supply chain vulnerabilities and cost fluctuations. Competition from alternative packaging materials, particularly plastic containers, presents ongoing challenges in price-sensitive market segments.

Regulatory compliance requirements for food safety, pharmaceutical standards, and environmental regulations necessitate continuous investment in quality systems and process improvements. Market fragmentation and limited economies of scale in certain application segments restrict profitability potential. Transportation costs for heavy glass containers impact competitiveness in distant markets, particularly for export opportunities.

Export market expansion presents substantial opportunities for Algeria’s container glass manufacturers, leveraging the country’s strategic location and competitive production costs. African Continental Free Trade Area agreements create preferential access to growing markets across the continent, where demand for quality packaging solutions is increasing rapidly. European market proximity enables participation in high-value specialty glass segments with premium pricing potential.

Pharmaceutical sector growth offers significant opportunities as Algeria develops its domestic pharmaceutical manufacturing capabilities. Specialty glass applications including laboratory equipment, medical devices, and high-end cosmetic packaging represent high-margin market segments with limited local competition. Value-added services such as custom decoration, labeling, and packaging solutions can enhance profitability and customer relationships.

Circular economy initiatives create opportunities for glass recycling operations and closed-loop manufacturing systems. Technology partnerships with international glass manufacturers can facilitate knowledge transfer and access to advanced production techniques. Government procurement programs for public sector applications provide stable demand sources for local manufacturers. Tourism industry recovery generates demand for premium beverage and food packaging applications.

Supply chain dynamics within Algeria’s container glass market are characterized by increasing vertical integration and strategic partnerships between raw material suppliers, manufacturers, and end-users. Raw material availability provides competitive advantages, with local silica sand deposits ensuring stable feedstock supplies and cost predictability. Manufacturing efficiency improvements through technology adoption have enhanced production capacity utilization rates to approximately 78% across major facilities.

Demand patterns reflect seasonal variations particularly in beverage applications, with peak demand periods during summer months and religious celebrations. Price dynamics are influenced by energy costs, raw material prices, and competitive pressures from imported products. Quality requirements are becoming increasingly stringent as end-users adopt international standards and export market specifications.

Innovation trends focus on lightweight container designs, improved barrier properties, and enhanced aesthetic appeal through advanced decoration techniques. Market consolidation activities are emerging as smaller producers seek partnerships or acquisitions to achieve economies of scale. Sustainability initiatives are reshaping production processes with emphasis on energy efficiency and waste reduction achieving approximately 25% improvement in resource utilization.

Comprehensive market analysis for Algeria’s container glass sector employs multiple research methodologies to ensure accuracy and reliability of findings. Primary research activities include structured interviews with industry executives, manufacturing facility visits, and stakeholder consultations across the value chain. Secondary research encompasses analysis of government statistics, industry publications, trade data, and regulatory documentation.

Data collection processes utilize both quantitative and qualitative approaches, incorporating production statistics, trade flows, pricing information, and market trend analysis. Industry expert consultations provide insights into technical developments, competitive dynamics, and future market projections. MarkWide Research methodology ensures comprehensive coverage of market segments, regional variations, and end-user applications.

Validation procedures include cross-referencing multiple data sources, triangulation of findings, and verification through industry participant feedback. Market modeling techniques incorporate historical trends, current market conditions, and projected growth scenarios. Quality assurance protocols ensure data accuracy and analytical rigor throughout the research process.

Northern Algeria dominates container glass production and consumption, with major manufacturing facilities concentrated around Algiers, Oran, and Constantine. This region benefits from established industrial infrastructure, port access for raw material imports and product exports, and proximity to major consumer markets. Manufacturing capacity in northern regions accounts for approximately 85% of total national production, supported by skilled workforce availability and transportation networks.

Coastal regions demonstrate strong market demand driven by tourism, beverage consumption, and food processing industries. Mediterranean proximity facilitates export opportunities to European and Middle Eastern markets, with shipping costs remaining competitive for glass container products. Industrial zones in coastal areas provide integrated manufacturing ecosystems with supporting services and infrastructure.

Interior regions show growing potential for market development, particularly in agricultural processing and food packaging applications. Southern Algeria presents opportunities for specialized applications including pharmaceutical and chemical packaging, supported by emerging industrial developments. Regional distribution networks are expanding to serve growing demand in previously underserved markets, with logistics infrastructure improvements facilitating market access.

Market competition in Algeria’s container glass sector features a mix of domestic manufacturers, international joint ventures, and specialized producers serving niche applications. Leading market participants have established strong positions through strategic investments, technology adoption, and customer relationship development.

Competitive strategies emphasize quality improvement, cost optimization, and market diversification. Technology investments and capacity expansion projects are common among major players seeking to strengthen market positions. Strategic partnerships with international companies provide access to advanced manufacturing techniques and global distribution channels.

Product segmentation within Algeria’s container glass market reflects diverse application requirements and manufacturing capabilities. Primary product categories include bottles, jars, vials, and specialty containers, each serving distinct market segments with specific performance characteristics.

By Product Type:

By End-Use Application:

Beverage containers represent the largest and most established category within Algeria’s container glass market, driven by strong domestic consumption and export potential. Beer bottles constitute a significant portion of production volume, with local breweries and international brands requiring consistent quality and supply reliability. Soft drink bottles show steady demand growth, particularly in premium segments where glass packaging provides superior product protection and brand image enhancement.

Food packaging applications demonstrate increasing sophistication with growing demand for specialty jars and containers. Olive oil bottles represent a traditional strength given Algeria’s agricultural production, with opportunities for premium packaging solutions targeting export markets. Preserve jars and condiment containers serve both domestic food processing industries and artisanal producers seeking quality packaging solutions.

Pharmaceutical containers constitute a high-growth category with stringent quality requirements and regulatory compliance standards. Injection vials and medication bottles require precise manufacturing tolerances and chemical resistance properties. Cosmetic packaging applications emphasize aesthetic appeal and premium positioning, with opportunities for value-added services including decoration and custom designs. Industrial applications serve specialized chemical and laboratory markets with specific performance requirements.

Manufacturing advantages for container glass producers in Algeria include access to abundant raw materials, competitive production costs, and strategic geographic positioning. Cost efficiencies derived from local silica sand deposits and energy resources provide sustainable competitive advantages in regional markets. Export opportunities leverage Algeria’s location for accessing European, African, and Middle Eastern markets with favorable shipping costs and trade relationships.

End-user benefits include reliable supply sources, competitive pricing, and improving quality standards that meet international requirements. Food and beverage companies gain access to sustainable packaging solutions with superior product protection and brand enhancement capabilities. Pharmaceutical manufacturers benefit from local sourcing options that reduce supply chain risks and ensure regulatory compliance.

Economic benefits for Algeria include job creation, technology transfer, and reduced import dependency for packaging materials. Environmental advantages stem from glass recyclability and reduced transportation emissions through local production. Investment opportunities attract both domestic and foreign capital, contributing to industrial development and economic diversification objectives. Skills development programs enhance workforce capabilities and support broader industrial advancement initiatives.

Strengths:

Weaknesses:

Opportunities:

Threats:

Sustainability integration emerges as a dominant trend shaping Algeria’s container glass market, with manufacturers increasingly adopting eco-friendly production processes and circular economy principles. Glass recycling programs are expanding across urban areas, with collection rates improving by approximately 40% over recent years. Energy efficiency initiatives focus on furnace optimization and waste heat recovery systems to reduce environmental impact and operational costs.

Technology modernization accelerates across manufacturing facilities, with advanced furnace systems, automated production lines, and digital quality control systems becoming standard. Industry 4.0 adoption includes predictive maintenance, real-time monitoring, and data analytics to optimize production efficiency and product quality. Lightweight container designs reduce material usage while maintaining structural integrity and performance characteristics.

Premium packaging trends drive demand for decorative glass containers with enhanced aesthetic appeal and brand differentiation capabilities. Customization services including embossing, screen printing, and specialty coatings create value-added opportunities for manufacturers. Smart packaging integration explores incorporation of digital technologies and interactive features in glass container designs. Health and safety consciousness increases preference for glass packaging due to its inert properties and chemical resistance.

Manufacturing capacity expansion projects have significantly enhanced Algeria’s container glass production capabilities, with new facilities incorporating state-of-the-art technology and automation systems. International partnerships and joint ventures have facilitated technology transfer and market access, strengthening competitive positioning in regional markets. Quality certification achievements enable access to export markets with stringent requirements for pharmaceutical and food packaging applications.

Investment announcements from both domestic and foreign companies indicate continued confidence in market growth potential and strategic importance of Algeria’s glass industry. Research and development initiatives focus on product innovation, process optimization, and sustainability improvements. Workforce development programs address skills gaps through technical training and knowledge transfer from international partners.

Regulatory developments include updated standards for food safety, pharmaceutical compliance, and environmental protection that influence manufacturing practices and market requirements. Infrastructure improvements in transportation, energy supply, and industrial zones enhance operational efficiency and market accessibility. Trade agreements and export promotion initiatives expand market opportunities in neighboring countries and international markets.

Strategic recommendations for Algeria’s container glass market participants emphasize the importance of technology adoption, quality improvement, and market diversification. MarkWide Research analysis suggests that manufacturers should prioritize investments in modern production equipment and quality control systems to meet international standards and compete effectively in export markets.

Market positioning strategies should leverage Algeria’s competitive advantages in raw material access and strategic location while addressing weaknesses in technical capabilities and infrastructure. Partnership development with international glass manufacturers can accelerate technology transfer and provide access to global distribution networks. Sustainability initiatives should be integrated into business strategies to align with market trends and regulatory requirements.

Capacity planning recommendations suggest gradual expansion aligned with market demand growth and export opportunities. Product diversification into high-value segments such as pharmaceuticals and specialty applications can improve profitability and market resilience. Skills development investments are essential for building technical capabilities and supporting long-term competitiveness. Quality management systems implementation ensures consistent product standards and customer satisfaction.

Long-term growth prospects for Algeria’s container glass market remain positive, supported by expanding domestic demand, export opportunities, and continued industrial development. Market expansion is projected to continue at robust growth rates of approximately 9.2% annually over the next five years, driven by economic diversification initiatives and increasing packaging demand across multiple sectors.

Technology advancement will continue reshaping the industry landscape, with smart manufacturing systems, advanced materials, and sustainable production processes becoming increasingly important. Export market development presents significant opportunities for revenue growth and market diversification, particularly in African and Mediterranean regions. Sustainability trends will drive innovation in recycling technologies and circular economy business models.

Investment flows are expected to remain strong as both domestic and international companies recognize Algeria’s strategic potential in container glass manufacturing. Regulatory evolution will continue supporting market development while ensuring environmental protection and product safety standards. Market maturation will lead to increased specialization and value-added services as competition intensifies and customer requirements become more sophisticated. Regional integration through trade agreements and economic partnerships will expand market access and growth opportunities.

Algeria’s container glass market represents a dynamic and promising sector within the country’s industrial landscape, characterized by strong growth potential, strategic advantages, and increasing market sophistication. The combination of abundant raw materials, strategic geographic positioning, and supportive government policies creates a favorable foundation for sustained market development and competitive positioning in regional markets.

Market opportunities span across traditional applications in food and beverages as well as emerging high-value segments including pharmaceuticals and specialty packaging. Technology adoption and quality improvement initiatives are enhancing manufacturing capabilities and enabling access to export markets with stringent requirements. Sustainability trends and circular economy principles are reshaping industry practices while creating new business opportunities.

Future success in Algeria’s container glass market will depend on continued investment in technology, skills development, and quality management systems. Strategic partnerships and international collaboration will remain essential for accessing advanced manufacturing techniques and global market opportunities. The market’s evolution toward greater specialization and value-added services positions Algeria as an emerging player in the regional container glass industry with significant potential for continued growth and development.

What is Container Glass?

Container glass refers to glass products designed for packaging and storing various goods, including beverages, food, and pharmaceuticals. It is known for its durability, recyclability, and ability to preserve the quality of its contents.

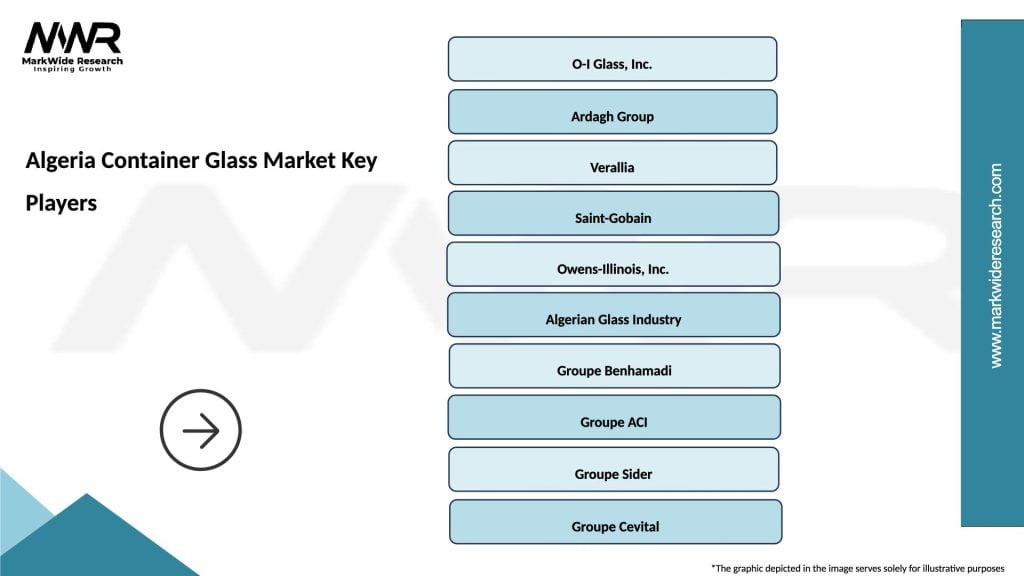

What are the key players in the Algeria Container Glass Market?

Key players in the Algeria Container Glass Market include Cevital, which is a major producer of glass containers, and Glasspack, known for its wide range of glass packaging solutions. Other notable companies include Algerian Glass and Sogeral, among others.

What are the growth factors driving the Algeria Container Glass Market?

The Algeria Container Glass Market is driven by increasing demand for sustainable packaging solutions and the growth of the beverage and food industries. Additionally, the rising consumer preference for glass over plastic due to health and environmental concerns is contributing to market expansion.

What challenges does the Algeria Container Glass Market face?

The Algeria Container Glass Market faces challenges such as high production costs and competition from alternative packaging materials like plastic and metal. Additionally, fluctuations in raw material prices can impact profitability for manufacturers.

What opportunities exist in the Algeria Container Glass Market?

Opportunities in the Algeria Container Glass Market include the potential for innovation in glass recycling technologies and the expansion of export markets for glass products. Furthermore, the growing trend towards eco-friendly packaging presents avenues for growth.

What trends are shaping the Algeria Container Glass Market?

Trends in the Algeria Container Glass Market include a shift towards lightweight glass containers and the adoption of smart packaging technologies. Additionally, there is an increasing focus on sustainability, with more companies investing in eco-friendly production processes.

Algeria Container Glass Market

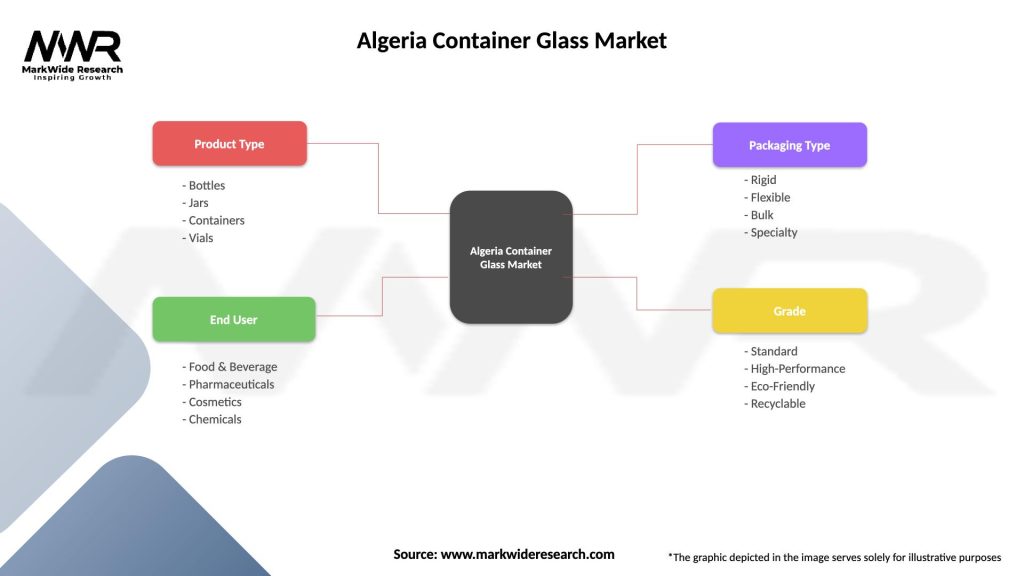

| Segmentation Details | Description |

|---|---|

| Product Type | Bottles, Jars, Containers, Vials |

| End User | Food & Beverage, Pharmaceuticals, Cosmetics, Chemicals |

| Packaging Type | Rigid, Flexible, Bulk, Specialty |

| Grade | Standard, High-Performance, Eco-Friendly, Recyclable |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the Algeria Container Glass Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at