444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The Aircraft Vertical Stabilizer Market refers to the segment of the aerospace industry that focuses on the production and supply of vertical stabilizers for aircraft. A vertical stabilizer, also known as a vertical fin or tail fin, is an important component of an aircraft’s tail assembly. It plays a crucial role in maintaining stability and control during flight by providing vertical stability and preventing yawing motions.

The market for aircraft vertical stabilizers is driven by the growing demand for commercial and military aircraft across the globe. As the aviation industry continues to expand, there is an increasing need for reliable and efficient aircraft components, including vertical stabilizers. These stabilizers are designed to withstand various aerodynamic forces and ensure the safe and stable flight of an aircraft.

Meaning

The aircraft vertical stabilizer is a critical part of an aircraft’s overall design. It is typically located at the rear of the aircraft and is attached to the vertical tail fin. The primary purpose of the vertical stabilizer is to provide stability during flight. It helps counteract the yawing motion of the aircraft, which is the side-to-side movement around the vertical axis.

The vertical stabilizer achieves stability by creating a force called “vertical lift.” This lift force is generated as the aircraft moves through the air. The vertical stabilizer’s shape and design, including its size, angle, and surface area, are carefully engineered to optimize its performance and ensure efficient flight characteristics.

In addition to providing stability, the vertical stabilizer also serves as a mounting point for other components, such as the rudder. The rudder, located at the trailing edge of the vertical stabilizer, is responsible for controlling the yawing motion of the aircraft. By deflecting the rudder, pilots can change the aircraft’s direction and maintain proper course control.

Executive Summary

The aircraft vertical stabilizer market is witnessing steady growth due to the increasing demand for aircraft in both the commercial and military sectors. As airlines expand their fleets and modernize their aircraft, the need for reliable and high-performance vertical stabilizers has become paramount.

Key market players are focusing on developing advanced vertical stabilizer technologies that offer enhanced aerodynamic efficiency, reduced weight, and improved structural strength. These innovations aim to improve fuel efficiency, reduce maintenance costs, and enhance overall aircraft performance.

The market is highly competitive, with several major players vying for market share. Companies are investing in research and development activities to stay ahead in the race and meet the evolving requirements of the aviation industry. Moreover, strategic partnerships and collaborations are being formed to leverage each other’s strengths and enhance product offerings.

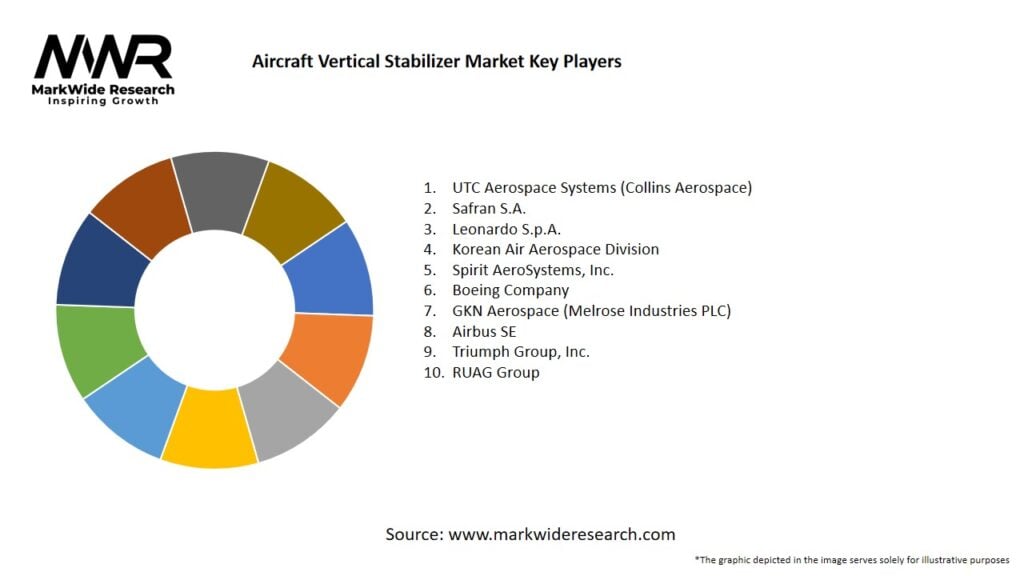

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The aircraft vertical stabilizer market is influenced by various dynamics, including market drivers, restraints, opportunities, and industry trends. Understanding these dynamics is crucial for market participants to make informed decisions and develop effective strategies.

Rising air passenger traffic and the need for aircraft fleet expansion are key drivers propelling market growth. Military modernization programs and the focus on lightweight design also contribute to market expansion. However, high development costs, COVID-19 impact, and intense competition pose challenges to market players.

Opportunities exist in the regional aircraft segment, UAVs, emerging markets, additive manufacturing, and collaborations/partnerships. The market is dynamic, with continuous advancements in materials, manufacturing techniques, and safety regulations. Adapting to these dynamics is essential for sustained growth in the aircraft vertical stabilizer market.

Regional Analysis

The aircraft vertical stabilizer market is analyzed across various regions, including North America, Europe, Asia-Pacific, Latin America, and the Middle East and Africa.

North America: North America has a well-established aerospace industry, with the presence of major aircraft manufacturers, such as Boeing and Airbus. The region accounts for a significant share of the aircraft vertical stabilizer market due to the high demand for commercial and military aircraft. The United States is a major contributor to market growth in this region.

Europe: Europe is another prominent region in the aircraft vertical stabilizer market. The region is home to several renowned aircraft manufacturers and suppliers. Countries like Germany, France, and the United Kingdom have a strong aerospace industry presence. The demand for vertical stabilizers in Europe is driven by the region’s focus on advanced aerospace technologies.

Asia-Pacific: Asia-Pacific is witnessing rapid growth in the aircraft vertical stabilizer market, primarily due to the increasing air travel demand in countries like China and India. Rising defense expenditures and the growth of regional airlines contribute to the market’s expansion in this region.

Latin America: Latin America is an emerging market for the aircraft vertical stabilizer. The region has seen significant growth in air travel and has witnessed investments in regional aircraft to enhance connectivity. Brazil, Mexico, and Colombia are the key contributors to market growth in Latin America.

Middle East and Africa: The Middle East and Africa region have shown promising growth in the aircraft vertical stabilizer market. The region’s expanding aviation industry, driven by factors like tourism and economic development, is creating opportunities for vertical stabilizer manufacturers.

Each region has its unique characteristics and market drivers. Understanding regional dynamics and tailoring strategies accordingly can help companies gain a competitive edge and capture market share.

Competitive Landscape

Leading Companies in the Aircraft Vertical Stabilizer Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

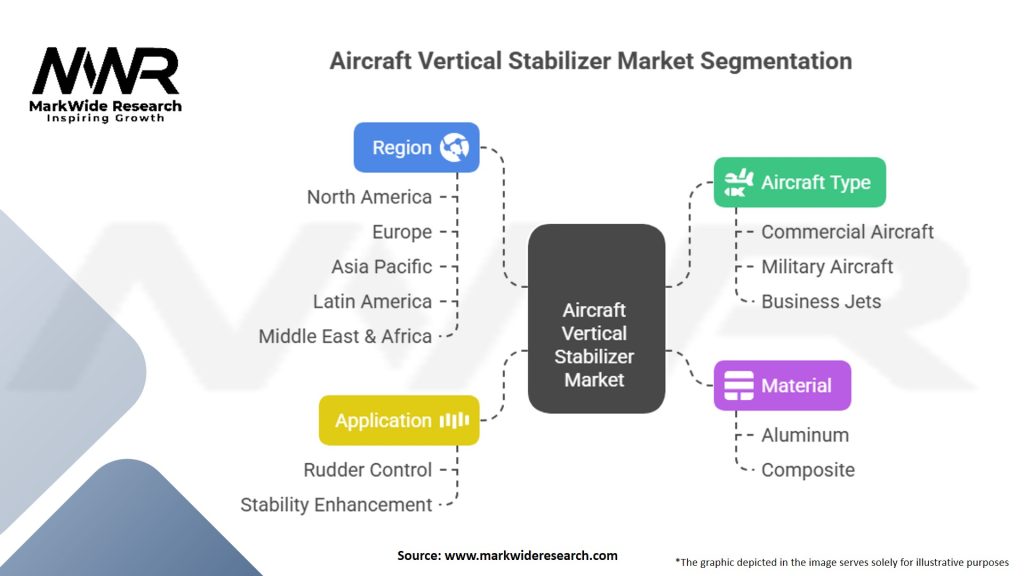

The aircraft vertical stabilizer market can be segmented based on aircraft type, material type, and end-user.

By Aircraft Type:

By Material Type:

By End-User:

Segmentation enables a deeper understanding of the market dynamics and helps identify specific target markets for vertical stabilizer manufacturers.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

Industry participants and stakeholders can leverage these benefits to drive growth, build competitive advantages, and establish themselves as trusted players in the aircraft vertical stabilizer market.

SWOT Analysis

A SWOT (Strengths, Weaknesses, Opportunities, and Threats) analysis provides an overview of the internal and external factors influencing the aircraft vertical stabilizer market.

Strengths:

Weaknesses:

Opportunities:

Threats:

Understanding the SWOT factors helps industry participants develop strategies to leverage strengths, address weaknesses, capitalize on opportunities, and mitigate threats in the aircraft vertical stabilizer market.

Market Key Trends

Keeping abreast of these key trends enables companies to stay competitive, anticipate customer needs, and align their product development strategies with industry advancements.

Covid-19 Impact

The COVID-19 pandemic has significantly impacted the aircraft vertical stabilizer market, as it has had a profound effect on the global aviation industry. The pandemic led to a sharp decline in air travel demand, flight cancellations, and reduced aircraft production rates.

During the pandemic, airlines faced financial challenges, resulting in the deferral or cancellation of aircraft orders. This, in turn, affected the demand for vertical stabilizers. Manufacturers experienced supply chain disruptions due to factory closures, travel restrictions, and reduced workforce availability.

However, as travel restrictions ease and vaccination rates increase, the aviation industry is showing signs of recovery. Governments and industry stakeholders are implementing measures to restore passenger confidence and stimulate air travel demand. As a result, the demand for new aircraft is expected to gradually recover, positively impacting the aircraft vertical stabilizer market.

Manufacturers have also adapted their operations to ensure employee safety, maintain production capabilities, and meet customer requirements. Companies have implemented enhanced safety protocols, digitalization initiatives, and remote working arrangements to navigate the challenges posed by the pandemic.

The long-term impact of COVID-19 on the aircraft vertical stabilizer market will depend on the pace of the global aviation industry’s recovery. While uncertainties remain, the gradual resumption of air travel and the industry’s resilience are expected to drive market growth in the post-pandemic era.

Key Industry Developments

These industry developments highlight the ongoing efforts to improve vertical stabilizer performance, efficiency, and sustainability. Manufacturers are leveraging advanced technologies and collaborating to meet the evolving demands of the aerospace industry.

Analyst Suggestions

Future Outlook

The future outlook for the aircraft vertical stabilizer market is positive, driven by factors such as increasing air travel demand, military modernization programs, and technological advancements. As the aviation industry recovers from the impacts of the COVID-19 pandemic, the demand for new aircraft and vertical stabilizers is expected to rebound.

Continued focus on lightweight design, aerodynamic efficiency, and sustainability will shape the market’s future. Advancements in composite materials, additive manufacturing, and electric aircraft technologies will further influence vertical stabilizer design and performance.

Collaborations and partnerships among industry stakeholders will play a crucial role in driving innovation and meeting evolving customer requirements. Manufacturers will need to invest in research and development, leverage technological advancements, and ensure compliance with safety regulations to remain competitive in the market.

While challenges such as high development costs, competitive pressures, and regulatory compliance persist, strategic initiatives and an agile approach will position companies for success in the aircraft vertical stabilizer market.

Conclusion

The aircraft vertical stabilizer market plays a critical role in ensuring the stability and control of aircraft during flight. The market is driven by the increasing demand for commercial and military aircraft worldwide. Technological advancements, lightweight design, and a focus on sustainability are key trends shaping the market’s future.

Manufacturers need to focus on continuous innovation, collaboration, and a customer-centric approach to meet the evolving needs of the aerospace industry. The COVID-19 pandemic has presented challenges, but as the aviation industry recovers, the demand for new aircraft and vertical stabilizers is expected to rebound.

What is Aircraft Vertical Stabilizer?

An Aircraft Vertical Stabilizer is a crucial component of an aircraft’s tail structure, designed to provide stability and control during flight. It helps maintain the aircraft’s directional stability and is typically paired with a horizontal stabilizer.

What are the key players in the Aircraft Vertical Stabilizer Market?

Key players in the Aircraft Vertical Stabilizer Market include Boeing, Airbus, and Lockheed Martin, which are known for their advanced aerospace technologies and manufacturing capabilities. These companies focus on innovation and quality to meet the demands of the aviation industry, among others.

What are the growth factors driving the Aircraft Vertical Stabilizer Market?

The Aircraft Vertical Stabilizer Market is driven by the increasing demand for fuel-efficient aircraft and advancements in aerodynamics. Additionally, the rise in air travel and the need for modernized fleets contribute to market growth.

What challenges does the Aircraft Vertical Stabilizer Market face?

The Aircraft Vertical Stabilizer Market faces challenges such as stringent regulatory requirements and the high costs associated with research and development. Additionally, competition from alternative designs and materials can hinder market expansion.

What opportunities exist in the Aircraft Vertical Stabilizer Market?

Opportunities in the Aircraft Vertical Stabilizer Market include the development of lightweight materials and the integration of smart technologies for enhanced performance. The growing trend towards electric and hybrid aircraft also presents new avenues for innovation.

What trends are shaping the Aircraft Vertical Stabilizer Market?

Trends in the Aircraft Vertical Stabilizer Market include the increasing use of composite materials for weight reduction and improved aerodynamics. Additionally, advancements in manufacturing techniques, such as additive manufacturing, are revolutionizing production processes.

Aircraft Vertical Stabilizer Market

| Segmentation | Details |

|---|---|

| Aircraft Type | Commercial Aircraft, Military Aircraft, Business Jets |

| Material | Aluminum, Composite |

| Application | Rudder Control, Stability Enhancement |

| Region | North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Aircraft Vertical Stabilizer Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at