444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The aircraft fuel nozzle market plays a crucial role in the aviation industry as it is responsible for delivering fuel to aircraft engines efficiently and safely. Fuel nozzles are vital components that control the flow and atomization of fuel, ensuring optimal combustion and engine performance. The market for aircraft fuel nozzles has witnessed significant growth in recent years, driven by the increasing demand for air travel and the modernization of existing aircraft fleets.

Meaning

Aircraft fuel nozzles are specialized components designed to inject fuel into aircraft engines at precise flow rates and spray patterns. These nozzles are engineered to deliver fuel efficiently, maximizing combustion and minimizing emissions. They play a critical role in maintaining the overall performance and safety of aircraft engines. Fuel nozzles need to withstand high temperatures, pressures, and corrosive environments, making them a key component in ensuring the reliability and efficiency of aircraft operations.

Executive Summary

The aircraft fuel nozzle market has experienced steady growth in recent years, driven by factors such as increasing air travel, the need for fuel-efficient aircraft, and advancements in nozzle technology. The market is characterized by intense competition among key players who strive to offer innovative and reliable fuel nozzle solutions. The industry has witnessed significant investments in research and development to enhance nozzle performance, durability, and fuel atomization capabilities. The market is expected to continue its growth trajectory in the coming years, supported by emerging technologies and the expansion of the aviation industry.

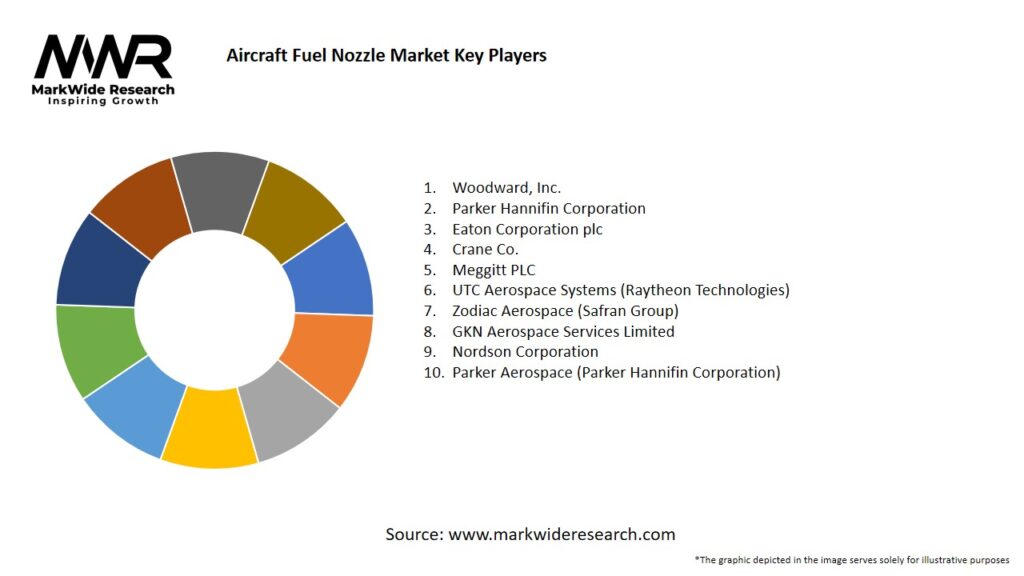

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

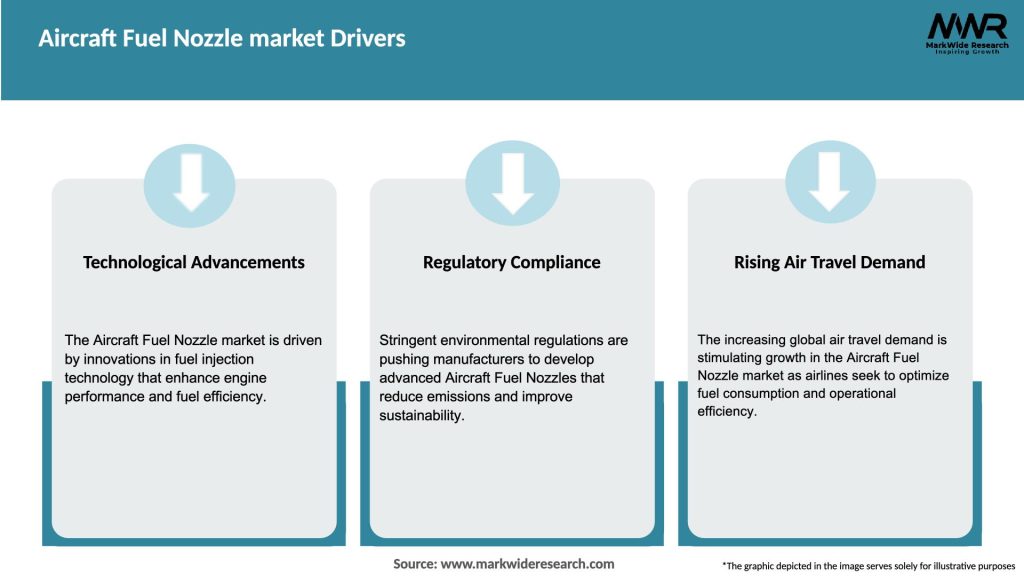

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The aircraft fuel nozzle market is driven by various dynamics, including technological advancements, regulatory frameworks, economic factors, and industry collaborations. These dynamics shape the market landscape and influence the strategies of key players. Understanding the market dynamics is crucial for fuel nozzle manufacturers to identify opportunities, overcome challenges, and stay competitive in the market.

Technological advancements play a significant role in fuel nozzle development. Companies invest in research and development to enhance nozzle design, material selection, and fuel control capabilities. Additive manufacturing techniques are gaining popularity, allowing for complex geometries and improved nozzle performance. Integrated sensors and actuators enable real-time monitoring and precise fuel control, contributing to overall engine efficiency.

Regulatory frameworks and environmental concerns are driving the demand for fuel-efficient engines and advanced fuel nozzle systems. Governments and regulatory bodies worldwide are implementing stringent emission standards and promoting sustainable aviation practices. Compliance with these regulations requires aircraft manufacturers and airlines to invest in fuel nozzle technologies that minimize emissions and improve fuel efficiency.

Economic factors, including fuel prices and market conditions, influence the demand for aircraft and, consequently, the demand for fuel nozzles. Fluctuations in fuel prices impact airlines’ operating costs, which may affect their purchasing decisions. Economic downturns and reduced airline budgets can delay fleet expansions and impact aftermarket sales of fuel nozzles.

Industry collaborations and partnerships are common in the aircraft fuel nozzle market. Fuel nozzle manufacturers often collaborate with engine manufacturers to develop integrated fuel system solutions that optimize performance and efficiency. These collaborations foster innovation, shared expertise, and mutual benefits for both parties.

Overall, the aircraft fuel nozzle market is dynamic and evolving, driven by technological advancements, regulatory frameworks, economic factors, and industry collaborations. Staying abreast of these dynamics and responding to market trends and demands is essential for fuel nozzle manufacturers to succeed in this competitive industry. Adapting to emerging technologies, complying with regulatory requirements, and forging strategic partnerships can help fuel nozzle manufacturers capitalize on market opportunities and overcome challenges.

Regional Analysis

The aircraft fuel nozzle market can be analyzed on a regional basis to understand the dynamics and growth prospects in different geographical areas. The market is influenced by factors such as air traffic growth, fleet modernization initiatives, and economic conditions specific to each region. Here is a brief analysis of some key regions in the aircraft fuel nozzle market:

Competitive Landscape

Leading Companies in the Aircraft Fuel Nozzle Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

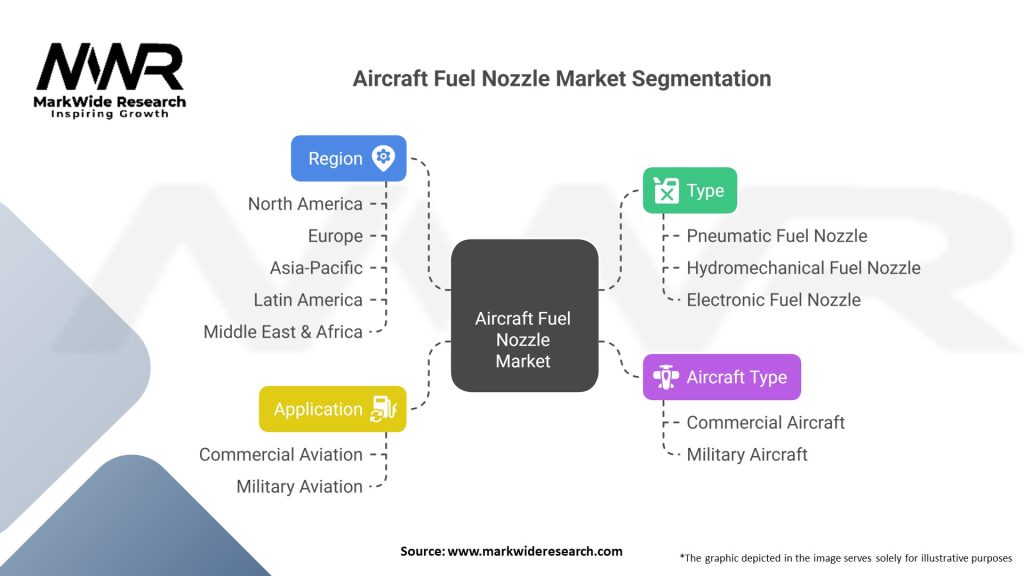

Segmentation

The aircraft fuel nozzle market can be segmented based on various factors, including nozzle type, aircraft type, engine type, and end-user. Segmentation helps in understanding specific market segments and their unique requirements. Here are some common segmentation categories:

Segmentation allows fuel nozzle manufacturers to tailor their products and strategies to specific customer segments, addressing their unique needs and preferences. It enables companies to focus their resources effectively and provide targeted solutions in the market.

Category-wise Insights

Segment-wise insights enable fuel nozzle manufacturers to identify the key growth areas within the market and align their product development, marketing, and sales strategies accordingly. By understanding the unique requirements and trends in each segment, manufacturers can tailor their offerings to meet customer demands effectively.

Key Benefits for Industry Participants and Stakeholders

Participating in the aircraft fuel nozzle market provides various benefits for industry participants and stakeholders:

Industry participants and stakeholders in the aircraft fuel nozzle market can leverage these benefits to drive their business growth, enhance their competitive position, and contribute to the advancement of the aviation industry as a whole.

SWOT Analysis

Conducting a SWOT (Strengths, Weaknesses, Opportunities, and Threats) analysis provides a comprehensive understanding of the internal and external factors impacting the aircraft fuel nozzle market. Here is a SWOT analysis for the market:

Strengths:

Weaknesses:

Opportunities:

Threats:

By analyzing the strengths, weaknesses, opportunities, and threats, fuel nozzle manufacturers can develop effective strategies to capitalize on their strengths, overcome weaknesses, exploit opportunities, and mitigate threats in the aircraft fuel nozzle market. This analysis helps in strategic decision-making, resource allocation, and positioning in the market.

Market Key Trends

The aircraft fuel nozzle market is influenced by various key trends that shape its dynamics and future prospects. Staying abreast of these trends is essential for fuel nozzle manufacturers to anticipate market needs and adapt their strategies accordingly. Here are some key trends in the market:

Covid-19 Impact

The Covid-19 pandemic has had a profound impact on the aviation industry, including the aircraft fuel nozzle market. The global travel restrictions, reduced passenger demand, and grounded fleets have resulted in a significant decline in aircraft production and aftermarket activities. As a result, the demand for fuel nozzles has been negatively affected.

During the pandemic, airlines focused on cost-cutting measures and fleet preservation rather than investing in new aircraft or upgrading existing fleets. This slowdown in aircraft orders and deliveries directly impacted the demand for fuel nozzle systems. The aftermarket segment also experienced a decline as airlines reduced maintenance and repair activities due to decreased flight operations.

However, as the industry gradually recovers from the pandemic, there are signs of optimism. The resumption of air travel, the lifting of travel restrictions, and the rollout of vaccination programs provide hope for the revival of the aviation industry. As airlines resume operations and restore their fleets, the demand for fuel nozzle systems is expected to rebound.

Moreover, the pandemic has highlighted the importance of fuel efficiency, emission reduction, and sustainable aviation practices. As the industry rebuilds, there is an increased focus on fuel efficiency and emissions reduction. This presents opportunities for fuel nozzle manufacturers to provide innovative solutions that align with the industry’s sustainability goals.

The pandemic has also accelerated certain trends in the market. For example, the adoption of digital technologies and smart fuel nozzle systems has gained traction as airlines seek to optimize maintenance processes and enhance operational efficiency. Remote monitoring, predictive maintenance, and data analytics have become even more crucial in ensuring the reliability and performance of fuel nozzle systems.

While the immediate impact of the pandemic has been challenging for the aircraft fuel nozzle market, the gradual recovery of the aviation industry and the shift towards a greener and more efficient future provide opportunities for growth and innovation. Fuel nozzle manufacturers that can adapt to the changing market landscape and align their offerings with industry trends and requirements are well-positioned to recover and thrive in the post-pandemic era.

Key Industry Developments

The aircraft fuel nozzle market is marked by continuous developments aimed at improving performance, efficiency, and sustainability. Industry players are investing in research and development to introduce new technologies and address market needs. Here are some key industry developments in the aircraft fuel nozzle market:

These key industry developments reflect the industry’s commitment to enhancing performance, efficiency, and sustainability in aircraft fuel nozzle systems. By investing in research, fostering collaboration, and embracing emerging technologies, fuel nozzle manufacturers are driving the evolution of the market and shaping the future of aviation.

Analyst Suggestions

Based on the analysis of the aircraft fuel nozzle market and industry trends, here are some suggestions for fuel nozzle manufacturers to navigate the market successfully:

By implementing these suggestions, fuel nozzle manufacturers can position themselves for success in the highly competitive aircraft fuel nozzle market. Embracing innovation, sustainability, collaboration, and customer-centric approaches will help manufacturers navigate the evolving industry landscape and capitalize on emerging opportunities.

Future Outlook

The future outlook for the aircraft fuel nozzle market is optimistic, driven by the growing demand for fuel-efficient aircraft, increasing focus on sustainability, and technological advancements in nozzle design and fuel control systems. While the COVID-19 pandemic has presented challenges, the gradual recovery of the aviation industry and the industry’s commitment to environmental sustainability provide opportunities for market growth.

Fuel nozzle manufacturers will continue to invest in research and development to enhance nozzle performance, optimize fuel combustion, and reduce emissions. Technological advancements, such as additive manufacturing, digitalization, and IoT integration, will play a significant role in the development of advanced fuel nozzle solutions.

The expansion of aviation markets in emerging economies, along with the need for fleet modernization and retrofit solutions, will drive the demand for fuel nozzle systems. Collaborative partnerships between fuel nozzle manufacturers, engine manufacturers, and airlines will foster innovation and the development of integrated fuel management systems that improve overall engine performance and efficiency.

Overall, the future of the aircraft fuel nozzle market looks promising, with opportunities for growth, innovation, and collaboration. By staying at the forefront of technology, embracing sustainability, and aligning with industry trends, fuel nozzle manufacturers can position themselves for success in the evolving aviation industry.

Conclusion

The aircraft fuel nozzle market is a vital component of the aviation industry, playing a crucial role in ensuring efficient fuel delivery, optimal combustion, and engine performance. Fuel nozzle manufacturers face both challenges and opportunities in this dynamic market.

Understanding market dynamics, technological advancements, and customer requirements is essential for fuel nozzle manufacturers to stay competitive. Key market insights indicate the growing demand for fuel-efficient aircraft, advancements in nozzle technology, and stringent emission regulations driving the market.

While there are market drivers such as rising air passenger traffic, fuel efficiency requirements, and technological advancements, there are also market restraints like high development costs and certification processes. However, market opportunities arise from the growing demand for next-generation aircraft, retrofitting existing aircraft, emerging aviation markets, and collaboration with engine manufacturers. Regional analysis highlights the significance of markets such as North America, Europe, Asia-Pacific, the Middle East, and Africa, and Latin America. Understanding regional dynamics is crucial for fuel nozzle manufacturers to cater to specific market needs and leverage growth opportunities.

What is Aircraft Fuel Nozzle?

An Aircraft Fuel Nozzle is a critical component in aircraft engines that atomizes and delivers fuel into the combustion chamber, ensuring efficient fuel-air mixing for optimal engine performance.

What are the key players in the Aircraft Fuel Nozzle market?

Key players in the Aircraft Fuel Nozzle market include Honeywell International Inc., Woodward, Inc., and Eaton Corporation, among others.

What are the main drivers of growth in the Aircraft Fuel Nozzle market?

The growth of the Aircraft Fuel Nozzle market is driven by the increasing demand for fuel-efficient engines, advancements in nozzle technology, and the expansion of the aviation industry.

What challenges does the Aircraft Fuel Nozzle market face?

Challenges in the Aircraft Fuel Nozzle market include stringent regulatory requirements, high manufacturing costs, and the need for continuous innovation to meet performance standards.

What opportunities exist in the Aircraft Fuel Nozzle market?

Opportunities in the Aircraft Fuel Nozzle market include the development of advanced materials for nozzles, the rise of electric and hybrid aircraft, and increasing investments in aerospace R&D.

What trends are shaping the Aircraft Fuel Nozzle market?

Trends in the Aircraft Fuel Nozzle market include the integration of smart technologies for monitoring performance, a shift towards sustainable aviation fuels, and the adoption of additive manufacturing techniques.

Aircraft Fuel Nozzle Market Segmentation

| Segmentation Details | Information |

|---|---|

| Type | Pneumatic Fuel Nozzle, Hydromechanical Fuel Nozzle, Electronic Fuel Nozzle |

| Aircraft Type | Commercial Aircraft, Military Aircraft |

| Application | Commercial Aviation, Military Aviation |

| Region | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Aircraft Fuel Nozzle Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at