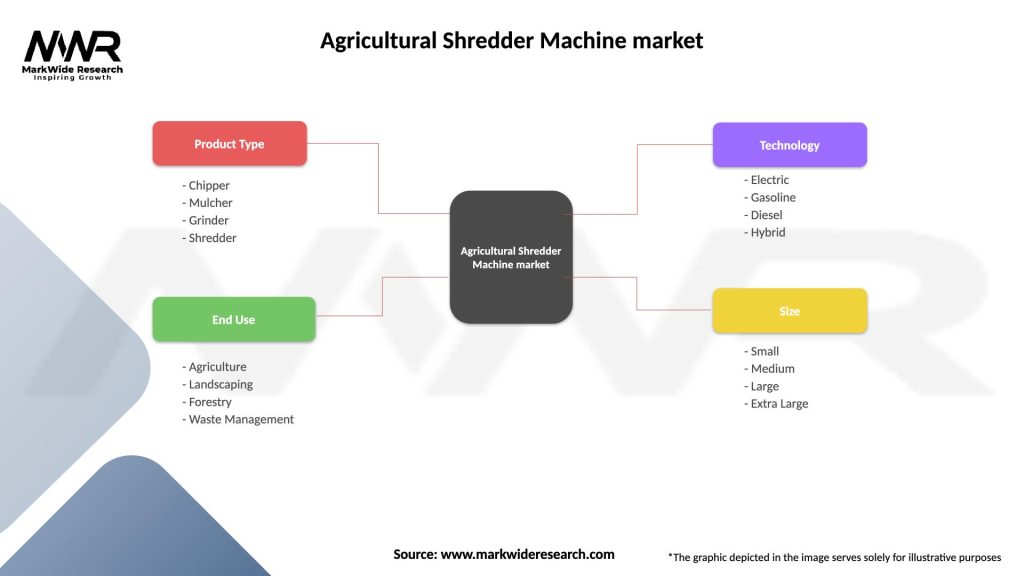

Segmentation

-

By Power Source: Tractor‑Mounted; Self‑Propelled; PTO‑Driven; Electric‑Powered

-

By Power Rating: Low (<50 HP); Medium (50–150 HP); High (>150 HP)

-

By Application: Field Crop Residue; Orchard & Vineyard Pruning; Fodder Chopping; Bioenergy Feedstock

-

By End‑User: Smallholder Farmers; Commercial Farmers; Custom Service Providers; Bioenergy Producers

-

By Region: Asia‑Pacific; Europe; North America; Latin America; Middle East & Africa

Category‑wise Insights

-

Field Crop Shredders: High‑throughput rotary units optimized for broadacre residues like stubble and straw.

-

Orchard Mulchers: Flail shredders with robust rotor designs capable of handling woody prunings.

-

Fodder Choppers: Specialized for crop silage preparation, often integrated with forage wagons.

-

Electric Shredders: Emerging segment aimed at low‑noise, zero‑emission operation in peri‑urban and regulatory‑sensitive areas.

Key Benefits for Industry Participants and Stakeholders

-

Enhanced Soil Fertility: Shredded residues decompose faster, returning nutrients and improving structure.

-

Regulatory Compliance: Mechanical shredding meets legal requirements in regions banning field burning.

-

Operational Efficiency: Reduced field passes compared to manual removal or baling, saving time and fuel.

-

New Revenue Streams: Sale of shredded biomass for bioenergy or animal bedding diversifies farm income.

-

Sustainability Credentials: Adoption of residue shredders supports circular agriculture and ESG reporting.

SWOT Analysis

Strengths:

-

Proven technology with clear agronomic and environmental benefits.

-

Wide range of configurations for diverse farm sizes and residue types.

Weaknesses:

-

High capital and maintenance costs for large, self‑propelled units.

-

Dependence on compatible tractors and power availability for PTO models.

Opportunities:

-

Growing interest in regenerative agriculture and soil carbon sequestration practices.

-

Expansion of custom hiring centers and service contractors in under‑mechanized regions.

Threats:

-

Competition from alternative residue management methods (e.g., baling, direct incorporation).

-

Volatile agricultural revenues may constrain farmer investment capabilities.

Market Key Trends

-

Precision Residue Management: Integration of GPS and yield‑map data to target shredding only where needed.

-

Electric and Hybrid Drives: Emergence of battery‑assist PTO motors and fully electric self‑propelled shredders.

-

AI‑Driven Monitoring: Onboard cameras and analytics to adjust rotor speed and knife engagement in real time.

-

Compact Foldable Designs: Transport‑friendly shredders optimized for smallholder and contract‑service operations.

-

Collaborative Platforms: Digital marketplaces connecting farmers with service providers offering shredding by the acre.

Covid‑19 Impact

-

Delayed Equipment Deliveries: Disruptions in supply chains briefly slowed machinery upgrades in 2020.

-

Increased Service Demand: Farmers outsourcing shredding to contractors to manage labor shortages and maintain social distancing.

-

Rental Model Growth: COVID‑era cash constraints drove greater adoption of rental and custom‑contractor shredding services.

-

Accelerated Mechanization Incentives: Stimulus programs in key markets included grants for machinery purchases, boosting shredder sales.

Key Industry Developments

-

John Deere Electric Mulcher Demo: Prototype battery‑powered, zero‑emission flail shredder unveiled for European trials.

-

Kubota Smart Shredder Launch: Introduction of telematics‑enabled PTO shredder with residue‑type automatic mode selection.

-

Maschio Gaspardo Modular Rotor System: Patent of quick‑swap knife banks tailored for rapid changeovers between residue types.

-

Berti’s High‑Density Mulcher: New design doubles throughput while maintaining small particle size for bioenergy applications.

-

Newtec Service Platform: Launch of an online booking portal connecting farmers with local shredding contractors in sub‑Saharan Africa.

Analyst Suggestions

-

Embrace Service Models: OEMs should partner with contract‑service providers to offer turnkey shredding solutions.

-

Invest in Electrification: Accelerate development of electric‑drive shredders to meet tightening emission standards.

-

Enhance Digital Features: Integrate IoT sensors and AI‑based controls for adaptive shredding and remote diagnostics.

-

Develop Modular Offerings: Offer scalable attachments and knife options for multi‑crop compatibility, increasing utilization rates.

-

Expand Training Programs: Provide operator training and maintenance services to maximize uptime and residue management efficacy.

Future Outlook

The Agricultural Shredder Machine Market is poised for steady growth as global agricultural practices increasingly emphasize sustainability, residue valorization, and soil health. Innovation in electric and smart-shredding technologies will lower environmental footprints and enhance operational precision. Service‑based and rental models will democratize access to high‑capacity equipment, particularly among smallholders. As bioenergy and circular‑economy priorities converge, shredders will become central to integrated farm systems—transforming post‑harvest waste into value‑added inputs for feed, fuel, and soil amendment.

Conclusion

Agricultural shredders play a pivotal role in modern, sustainable farming systems—efficiently managing crop residues, improving soil quality, and enabling on‑farm biomass utilization. With evolving environmental regulations, mechanization initiatives, and technological advancements, the market for shredders will continue to expand and diversify. Stakeholders who innovate in electrification, digital integration, and service delivery will lead the way, fostering resilient and regenerative agricultural practices worldwide.