444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

The aerospace industry has witnessed significant growth in recent years, driving the demand for aerospace materials. These materials play a crucial role in manufacturing aircraft, spacecraft, and related components. The aerospace materials market encompasses a wide range of materials, including metals, alloys, composites, and ceramics, each with unique properties and applications.

Aerospace materials refer to the materials used in the construction and assembly of aerospace structures and systems. These materials need to meet stringent requirements for strength, durability, weight reduction, and resistance to extreme temperatures and environmental conditions. The choice of materials directly impacts the performance, safety, and overall efficiency of aerospace vehicles.

Executive Summary:

The aerospace materials market is experiencing steady growth due to the increasing demand for air travel, the rise in defense budgets, and advancements in space exploration. The market is driven by the need for lightweight materials that offer enhanced fuel efficiency, reduced emissions, and improved structural integrity. Key players in the aerospace materials industry are investing in research and development to introduce innovative materials that meet these requirements.

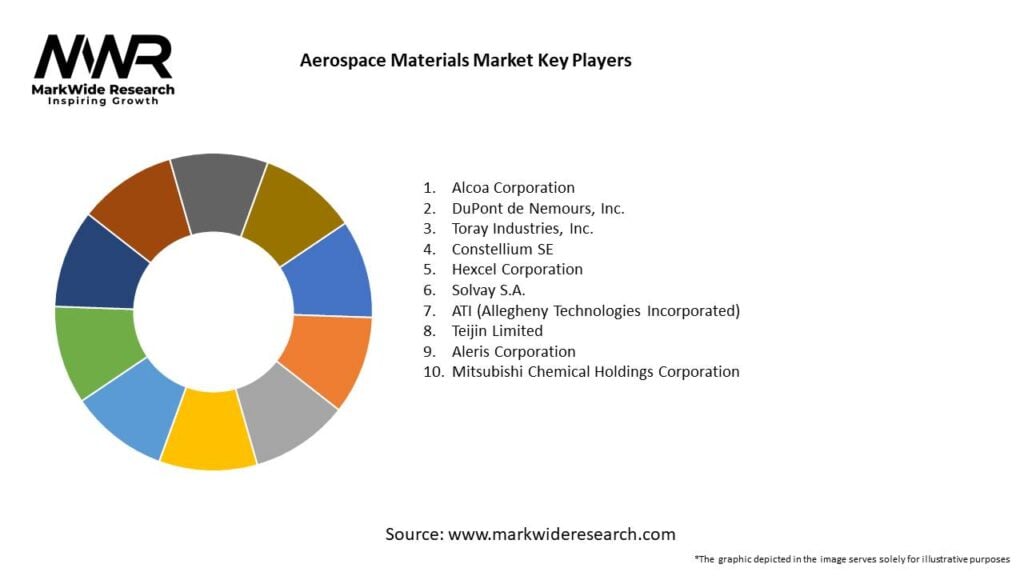

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights:

Market Drivers:

Market Restraints:

Market Opportunities:

Market Dynamics:

The aerospace materials market is highly influenced by technological advancements, regulatory frameworks, and market trends. It is a dynamic industry that demands continuous research and development to meet evolving customer needs and industry requirements.

Regional Analysis:

The aerospace materials market is segmented into North America, Europe, Asia-Pacific, Latin America, and the Middle East and Africa. North America holds a significant market share, driven by the presence of leading aerospace manufacturers and defense organizations. Europe and Asia-Pacific are also key regions in terms of aerospace materials consumption and production.

Competitive Landscape:

Leading companies in the Aerospace Materials Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation:

The aerospace materials market can be segmented based on material type, aircraft type, and end-use. By material type, the market includes metals, alloys, composites, ceramics, and others. Aircraft type segmentation covers commercial aircraft, military aircraft, and spacecraft. The end-use segment comprises structural components, engines, interiors, and others.

Category-wise Insights:

Key Benefits for Industry Participants and Stakeholders:

SWOT Analysis:

Market Key Trends:

Covid-19 Impact:

The Covid-19 pandemic has significantly impacted the aerospace industry, leading to a decline in air travel and aircraft deliveries. The aerospace materials market also faced disruptions in the supply chain and reduced demand. However, as the industry recovers, there are opportunities for the market to rebound, driven by the need for lightweight materials and technological advancements.

Key Industry Developments:

Key developments in the Aerospace Materials Market include:

Development of Sustainable Materials: Companies are working to develop eco-friendly materials, including recycled metals and bio-based composites, to meet growing demand for sustainable solutions in the aerospace sector.

Advances in Additive Manufacturing: 3D printing technology is becoming more prevalent in the aerospace industry, allowing for the creation of complex, lightweight components with minimal waste.

Growth in the Space Industry: The increasing number of private space missions is leading to the development of new materials that can withstand extreme conditions in space.

Analyst Suggestions:

Future Outlook:

The aerospace materials market is expected to witness steady growth in the coming years, driven by increasing air travel, the need for fuel-efficient aircraft, and advancements in materials science. The market will continue to evolve with the introduction of new materials and manufacturing techniques, shaping the future of the aerospace industry.

Conclusion:

The aerospace materials market is a critical component of the aerospace industry, providing the materials necessary for the construction of aircraft and spacecraft. With the demand for lightweight, high-performance materials on the rise, manufacturers and suppliers need to stay at the forefront of innovation. By embracing advancements in material science, collaborating with industry partners, and adapting to market trends, stakeholders can capitalize on the opportunities in the aerospace materials market and contribute to the growth and sustainability of the industry.

What are aerospace materials?

Aerospace materials refer to the specialized materials used in the construction of aircraft and spacecraft, including metals, composites, and polymers that provide strength, lightweight properties, and resistance to extreme conditions.

What are the key companies in the Aerospace Materials Market?

Key companies in the Aerospace Materials Market include Boeing, Airbus, Lockheed Martin, and Hexcel, among others.

What are the main drivers of growth in the Aerospace Materials Market?

The main drivers of growth in the Aerospace Materials Market include the increasing demand for fuel-efficient aircraft, advancements in composite materials, and the expansion of the aerospace industry in emerging markets.

What challenges does the Aerospace Materials Market face?

Challenges in the Aerospace Materials Market include the high cost of advanced materials, stringent regulatory requirements, and the need for continuous innovation to meet performance standards.

What opportunities exist in the Aerospace Materials Market?

Opportunities in the Aerospace Materials Market include the development of sustainable materials, the integration of smart materials, and the growing trend towards lightweight structures in aerospace design.

What trends are shaping the Aerospace Materials Market?

Trends shaping the Aerospace Materials Market include the increasing use of additive manufacturing, the rise of nanomaterials, and the focus on recycling and sustainability in material selection.

Aerospace Materials Market

| Segmentation Details | Description |

|---|---|

| By Material Type | Aluminum Alloys, Titanium Alloys, Composite Materials, Others |

| By Aircraft Type | Commercial Aircraft, Military Aircraft, Business & General Aviation, Others |

| By Region | North America, Europe, Asia Pacific, Middle East & Africa, Latin America |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the Aerospace Materials Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at