444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The acrylic polymer emulsion market is experiencing significant growth and is expected to continue its upward trajectory in the coming years. Acrylic polymer emulsion refers to a water-based, milky white liquid that consists of acrylic polymer particles suspended in water. These emulsions find wide applications across various industries, including paints and coatings, adhesives and sealants, textiles, paper coatings, and construction.

Meaning

Acrylic polymer emulsions are formed by the emulsion polymerization process, where monomers such as acrylic acid or esters are dispersed in water with the help of surfactants. The resulting emulsion is stable and can be used as a binder in various applications due to its excellent film-forming properties and versatility.

Executive Summary

The acrylic polymer emulsion market is witnessing robust growth due to the increasing demand for environmentally-friendly coatings and adhesives. These emulsions offer several advantages, including low volatile organic compound (VOC) content, good adhesion, flexibility, and durability. Moreover, their easy application and fast drying properties make them highly desirable in various industries.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Environmental Regulations: Stringent VOC regulations globally are accelerating the replacement of solvent‑borne systems with water‑borne acrylic emulsions.

Urbanization & Construction Boom: Rapid infrastructure projects in Asia, the Middle East, and Latin America are driving architectural paint demand.

Technological Innovations: Development of functional emulsions—antimicrobial, self‑cleaning, and conductive—broadens application horizons.

Value‑Added Applications: Growth in specialty adhesives and textiles expands the market beyond traditional coatings.

Bio‑Based Monomers: Emerging interest in renewable acrylate monomers boosts sustainable emulsion development.

Market Drivers

Low‑VOC Demand: Increasing health and environmental concerns propel water‑borne emulsion adoption.

Infrastructure Investments: Government spending on roads, bridges, and urban housing fuels coatings and construction mortars.

Industrial Coatings Growth: Automotive, aerospace, and marine sectors require durable, weather‑resistant coatings.

Adhesives & Sealants Expansion: E‑commerce packaging and hygiene adhesives drive pressure‑sensitive adhesive growth.

Emerging Economies: Rising disposable incomes and industrialization in Asia‑Pacific and Latin America.

Market Restraints

Raw Material Volatility: Fluctuations in acrylic monomer prices affect emulsion production costs.

Alternative Technologies: Competition from polyurethane dispersions (PUDs) and styrene‑acrylic blends.

Regulatory Hurdles: Complex regional regulations on biocides and monomer residues.

Performance Limitations: Need for high‑temperature or chemical‑resistant formulations may limit emulsion use without modification.

Infrastructure Gaps: In developing regions, lack of technical expertise can slow adoption of advanced emulsions.

Market Opportunities

Smart & Functional Coatings: Development of stimuli‑responsive, self‑healing, and antimicrobial emulsions.

Bio‑Based & Green Emulsions: Leveraging renewable acrylates to meet sustainability goals.

Digital Printing & Fiber Applications: Novel emulsions for inkjet printing textiles and paper.

Energy‑Efficient Buildings: Emulsions for cool‑roof coatings and insulating materials.

Healthcare & Hygiene: Specialty emulsions for medical adhesives and antimicrobial surfaces.

Market Dynamics

Supply Side: Advances in controlled polymerization techniques (e.g., RAFT, ATRP) enable narrow particle size distribution and precise Tg control. Scale‑up of bio‑acrylate monomers remains a focus.

Demand Side: Growth in do‑it‑yourself (DIY) paints, e‑commerce packaging, and automotive refinish coatings. Evolving consumer preferences for durable, eco‑friendly products drive innovation.

Economic & Policy: Trade policies impacting acrylate imports/exports, coupled with incentives for green technologies, shape regional competitiveness.

Regional Analysis

North America: Mature market with high regulatory compliance; growth driven by industrial coatings and specialty adhesives.

Europe: Strict VOC regulations and green building initiatives favor water‑borne emulsions; strong R&D ecosystem.

Asia‑Pacific: Fastest‑growing region; booming construction, automotive, and electronics sectors, led by China and India.

Latin America: Infrastructure expansion and urban housing projects create new demand; price sensitivity requires efficient production.

Middle East & Africa: Oil‑rich nations invest in mega‑projects; adoption of advanced emulsions tied to technology transfer and local production capabilities.

Competitive Landscape

Leading Companies in the Acrylic Polymer Emulsion Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

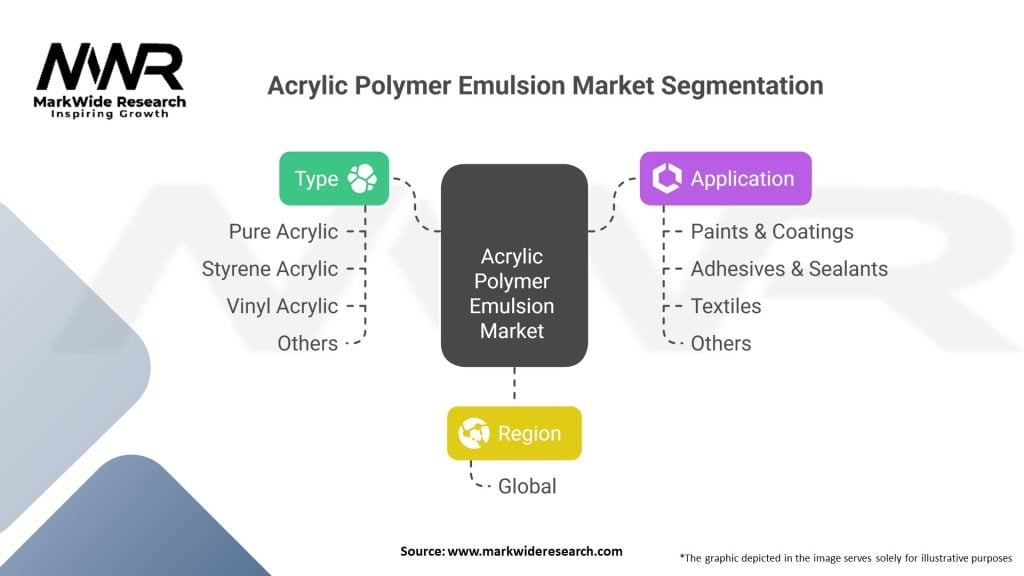

Segmentation

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic had a mixed impact on the acrylic polymer emulsion market. While the initial phase witnessed disruptions in the supply chain and reduced demand due to lockdown measures, the market gradually recovered as construction activities resumed and the demand for eco-friendly coatings increased. The pandemic highlighted the importance of sustainable and low VOC products, further driving the adoption of acrylic polymer emulsions.

Key Industry Developments

Analyst Suggestions

Future Outlook

The acrylic polymer emulsion market is poised for significant growth in the coming years. The increasing demand for environmentally-friendly coatings and adhesives, coupled with stringent regulations, will drive market expansion. Technological advancements and continuous innovation will contribute to the development of high-performance acrylic polymer emulsions. Geographically, Asia Pacific is expected to dominate the market, followed by Europe and North America. However, emerging economies present untapped opportunities for market players. Overall, the future outlook for the acrylic polymer emulsion market is promising, driven by sustainability initiatives and the need for superior coating and adhesive solutions.

Conclusion

The acrylic polymer emulsion market is experiencing steady growth and presents numerous opportunities for industry participants. The demand for eco-friendly coatings and adhesives, driven by environmental regulations and consumer preferences, is a key driver for market expansion. Manufacturers should focus on continuous innovation, strategic partnerships, and sustainable practices to capitalize on this growing market. With technological advancements and expanding end-use industries, the acrylic polymer emulsion market is expected to thrive in the foreseeable future.

What is Acrylic Polymer Emulsion?

Acrylic Polymer Emulsion is a water-based dispersion of acrylic polymers used in various applications such as paints, coatings, adhesives, and textiles. It offers excellent adhesion, flexibility, and durability, making it a popular choice in the manufacturing sector.

What are the key players in the Acrylic Polymer Emulsion market?

Key players in the Acrylic Polymer Emulsion market include BASF, Dow Chemical Company, and Arkema, among others. These companies are known for their innovative products and extensive research and development efforts in the field.

What are the growth factors driving the Acrylic Polymer Emulsion market?

The growth of the Acrylic Polymer Emulsion market is driven by increasing demand in the construction and automotive industries, as well as the rising trend towards eco-friendly and sustainable products. Additionally, the expansion of the paint and coatings sector contributes significantly to market growth.

What challenges does the Acrylic Polymer Emulsion market face?

The Acrylic Polymer Emulsion market faces challenges such as fluctuating raw material prices and stringent environmental regulations. These factors can impact production costs and limit the availability of certain materials used in formulations.

What opportunities exist in the Acrylic Polymer Emulsion market?

Opportunities in the Acrylic Polymer Emulsion market include the development of advanced formulations for specific applications, such as high-performance coatings and adhesives. Additionally, the growing demand for sustainable and low-VOC products presents a significant opportunity for innovation.

What trends are shaping the Acrylic Polymer Emulsion market?

Current trends in the Acrylic Polymer Emulsion market include the increasing use of bio-based emulsions and the integration of smart technologies in coatings. These trends reflect a shift towards sustainability and enhanced performance in various applications.

| Segment | Segmentation Details |

|---|---|

| Type | Pure Acrylic, Styrene Acrylic, Vinyl Acrylic, Others |

| Application | Paints & Coatings, Adhesives & Sealants, Textiles, Others |

| Region | Global |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Acrylic Polymer Emulsion Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at