444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The PID (Proportional-Integral-Derivative) Controller market has witnessed significant growth in recent years. A PID controller is an important component in control systems that helps maintain stability and accuracy in various industrial processes. It is widely used in industries such as manufacturing, oil and gas, chemical, and automotive, among others. The increasing demand for automation and process control systems has been a key driver for the growth of the PID controller market.

Meaning

A PID controller is a feedback control mechanism that continuously calculates an error value as the difference between a desired setpoint and the measured process variable. The controller then adjusts the control output to minimize this error and maintain the process variable at the desired setpoint. The PID controller combines three types of control actions: proportional, integral, and derivative, to provide accurate and stable control in various industrial applications.

Executive Summary

The PID controller market is experiencing steady growth due to its crucial role in maintaining process stability and accuracy. The market is driven by the increasing demand for automation and control systems across industries. The PID controller offers benefits such as improved efficiency, reduced downtime, and enhanced product quality. However, market growth is influenced by factors such as high initial costs and the need for skilled professionals to implement and maintain these controllers.

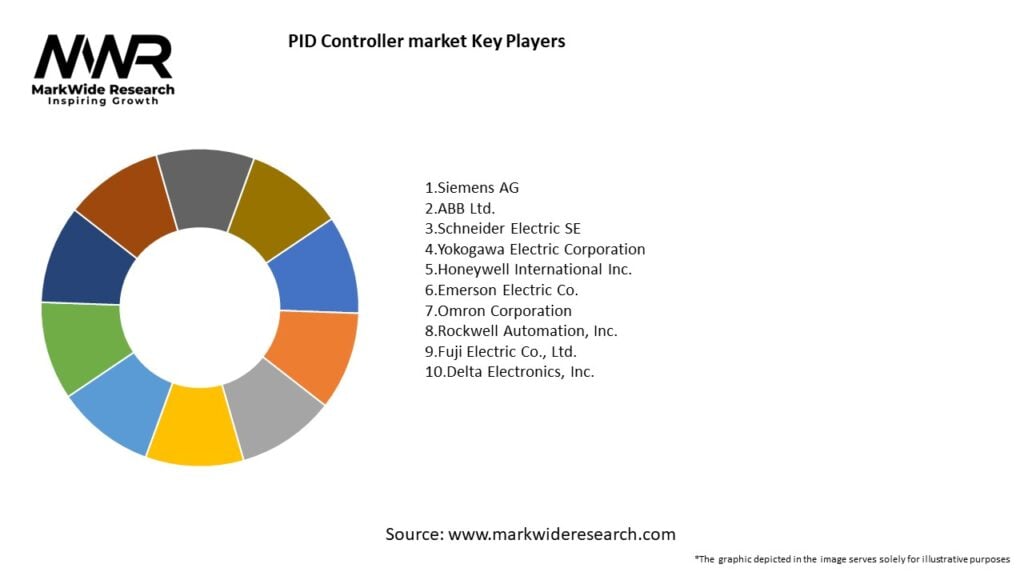

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

The PID controller market is primarily driven by the following factors:

Market Restraints

Despite the positive growth prospects, the PID controller market faces some challenges, including:

Market Opportunities

The PID controller market presents several opportunities for growth and expansion:

Market Dynamics

The PID controller market is influenced by various dynamics, including technological advancements, regulatory factors, and industry collaborations. These dynamics shape the market landscape and impact the growth and adoption of PID controllers in different industries and regions.

Regional Analysis

The PID controller market exhibits regional variations in terms of market size, growth potential, and adoption rates. The key regions analyzed in this report include North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa.

Competitive Landscape

Leading Companies in the PID Controller Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The PID controller market can be segmented based on various factors, including type, industry vertical, and geography.

The segmentation of the PID controller market allows for a detailed analysis of each segment’s growth potential, market trends, and customer preferences. It helps manufacturers and stakeholders identify target markets and develop tailored strategies for market penetration.

Category-wise Insights

Each category of PID controllers has its own advantages and is suitable for different applications and process requirements. Manufacturers and end-users need to understand these categories to select the most appropriate controller for their specific needs.

Key Benefits for Industry Participants and Stakeholders

The PID controller market offers several benefits for industry participants and stakeholders:

Key Benefits for Industry Participants and Stakeholders

The PID controller market has been experiencing substantial growth in recent years, creating numerous benefits for industry participants and stakeholders. One of the key advantages is the increased efficiency and accuracy in controlling industrial processes. PID (Proportional-Integral-Derivative) controllers play a critical role in regulating variables such as temperature, pressure, and flow rates, ensuring optimal performance and reducing the likelihood of errors.

Furthermore, PID controllers offer a cost-effective solution for automation and control systems. They enable precise control over various industrial processes, leading to enhanced productivity and reduced operational costs. By automating repetitive tasks and maintaining consistent control, PID controllers improve overall efficiency and minimize manual interventions. Another significant benefit of PID controllers is their adaptability and versatility. These controllers can be integrated into a wide range of industries, including manufacturing, oil and gas, chemical, pharmaceutical, and food processing. Regardless of the industry, PID controllers provide an effective means of regulating processes and maintaining desired setpoints.

Moreover, PID controllers offer real-time monitoring and adjustment capabilities, ensuring immediate response to changes in process variables. This feature allows for quick identification and correction of deviations, preventing any potential damage or disruption in the production line. By providing accurate and timely feedback control, PID controllers enhance product quality and customer satisfaction. Overall, the key benefits of PID controllers for industry participants and stakeholders include improved process efficiency, cost-effectiveness, adaptability to diverse industries, real-time monitoring, and enhanced product quality.

SWOT Analysis

A SWOT analysis provides insights into the strengths, weaknesses, opportunities, and threats in the PID controller market.

Strengths:

The PID controller market benefits from several strengths, including its long-established presence and wide acceptance in industrial automation. PID controllers have a proven track record of reliability and effectiveness, making them a trusted choice for process control. Additionally, their versatility and compatibility with different control systems contribute to their strength in the market.

Weaknesses:

One of the weaknesses of PID controllers lies in their complexity. Proper tuning and optimization of PID parameters require expertise and experience. In some cases, the tuning process can be time-consuming and challenging. Furthermore, PID controllers may struggle to handle certain nonlinear processes or systems with significant time delays, limiting their effectiveness in such scenarios.

Opportunities:

The PID controller market presents several opportunities for growth. The increasing demand for automation and process control in various industries provides a favorable environment for the market expansion. Additionally, advancements in technology, such as the integration of artificial intelligence and machine learning, offer potential opportunities for enhancing the capabilities and performance of PID controllers.

Threats:

The PID controller market faces competition from alternative control methods and technologies. Advanced control algorithms, such as model predictive control and fuzzy logic control, offer alternatives to PID controllers in certain applications. The availability of these alternative options poses a threat to the market dominance of PID controllers.

Market Key Trends

Several key trends are shaping the PID controller market and influencing its growth trajectory.

Covid-19 Impact

The COVID-19 pandemic has had a mixed impact on the PID controller market. On one hand, the widespread disruptions in manufacturing and industrial activities led to a temporary decline in the demand for PID controllers. Many industries faced challenges such as reduced production capacity, supply chain disruptions, and labor shortages, which affected the implementation of new control systems.

However, the pandemic also highlighted the importance of automation and remote control in maintaining operational continuity. Industries realized the need for resilient and adaptable control systems that could function effectively even during crises. As a result, there has been an increased focus on integrating PID controllers with IIoT and remote monitoring capabilities, ensuring that operations can continue smoothly even with limited physical presence.

Furthermore, the pandemic accelerated the adoption of digital transformation and automation across various industries. The need to minimize human intervention and ensure operational efficiency led to increased investments in control systems, including PID controllers. As industries recover from the pandemic’s impact and adapt to the new normal, the demand for PID controllers is expected to rebound and grow.

Key Industry Developments

The PID controller market has witnessed significant industry developments in recent years. Some notable developments include:

Analyst Suggestions

Industry analysts suggest several strategies and considerations for stakeholders in the PID controller market:

Future Outlook

The future outlook for the PID controller market is promising, driven by factors such as increasing industrial automation, the integration of advanced control algorithms, and the demand for energy-efficient solutions. The market is expected to witness steady growth as industries continue to prioritize process optimization, operational efficiency, and regulatory compliance. The integration of PID controllers with IIoT, artificial intelligence, and cloud computing will further expand their capabilities and applications. PID controllers will continue to play a crucial role in diverse industries, including manufacturing, energy, pharmaceuticals, and food processing. The ability to provide precise control, real-time monitoring, and adaptability to different processes positions PID controllers as essential tools in industrial automation.

To stay competitive in the evolving market, manufacturers should focus on innovation, customization, and collaboration with technology solution providers. By addressing industry challenges, improving performance, and providing value-added features, stakeholders can capitalize on the growing opportunities in the PID controller market.

Conclusion

The PID controller market offers several benefits for industry participants and stakeholders, including improved process efficiency, cost-effectiveness, adaptability, and real-time monitoring capabilities. While facing challenges from alternative control methods and technologies, PID controllers remain a trusted choice in industrial automation. The market is witnessing key trends such as the integration of PID controllers with IIoT, the adoption of advanced control algorithms, and the emphasis on energy efficiency. Despite the temporary impact of the COVID-19 pandemic, the demand for PID controllers is expected to rebound as industries recover and prioritize automation and control systems.

Industry developments such as cloud integration, wireless communication, and customization are shaping the PID controller market. Analyst suggestions include enhancing R&D efforts, collaborating with IIoT solution providers, focusing on energy efficiency, and providing user-friendly interfaces. The future outlook for the PID controller market is positive, with steady growth expected due to increasing industrial automation and the integration of advanced technologies. By staying innovative and addressing industry needs, stakeholders can leverage the opportunities in the PID controller market and contribute to industrial process optimization and efficiency.

PID Controller market

| Segmentation Details | Description |

|---|---|

| Product Type | Analog Controllers, Digital Controllers, Hybrid Controllers, Smart Controllers |

| End User | Manufacturing, Aerospace, Automotive OEMs, Energy Sector |

| Technology | Proportional Control, Integral Control, Derivative Control, Fuzzy Logic |

| Application | Temperature Control, Pressure Control, Flow Control, Level Control |

Leading Companies in the PID Controller Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at