Market Overview

The Low-frequency Sound-absorbing Insulation Materials market refers to a niche segment within the broader insulation materials industry. These specialized materials are designed to absorb and reduce low-frequency sound waves, providing enhanced noise control and acoustic comfort in various applications. The demand for low-frequency sound-absorbing insulation materials has been increasing steadily due to the growing awareness about the detrimental effects of noise pollution on human health and well-being.

Meaning

Low-frequency sound-absorbing insulation materials are specifically formulated materials that are used to minimize the transmission of low-frequency sound waves. These materials are engineered to absorb sound energy across a wide frequency range, typically below 500 Hz. By effectively reducing the transmission of low-frequency noise, they help create quieter and more comfortable environments in a range of settings, including residential, commercial, industrial, and transportation sectors.

Executive Summary

The Low-frequency Sound-absorbing Insulation Materials market has witnessed significant growth in recent years, driven by the rising demand for noise control solutions across various industries. These materials offer several advantages, including improved acoustic performance, energy efficiency, and enhanced occupant comfort. With increasing awareness about the importance of noise reduction, the market for low-frequency sound-absorbing insulation materials is expected to expand further in the coming years.

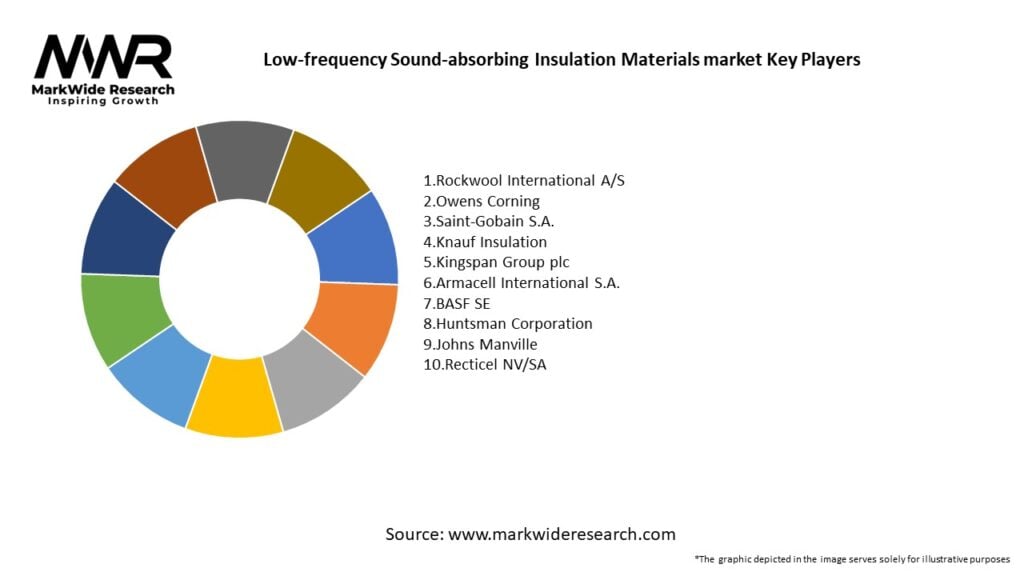

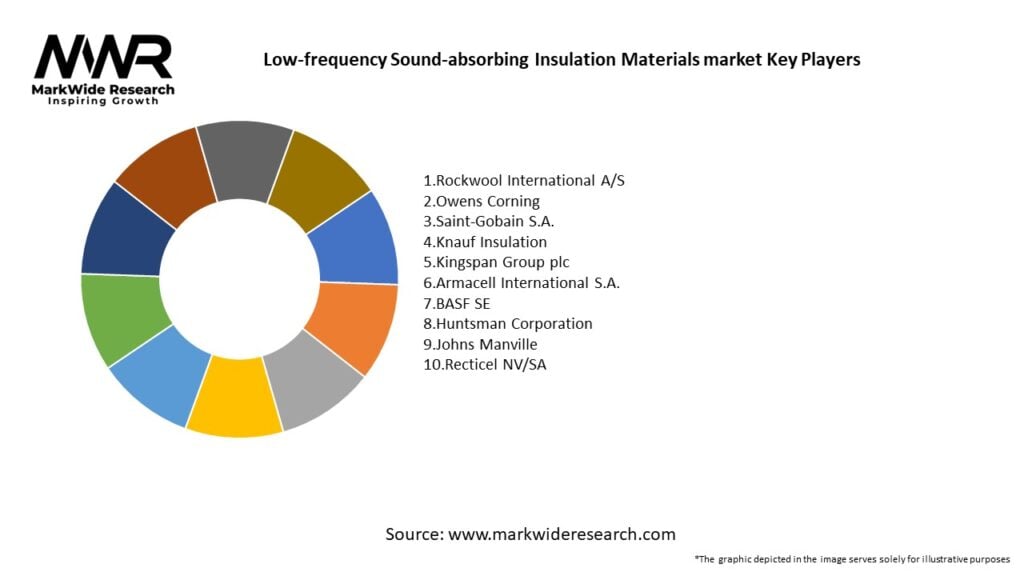

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

- Growing Noise Pollution Concerns: The rising awareness about the adverse effects of noise pollution on human health and productivity is a key driver of the low-frequency sound-absorbing insulation materials market. Governments and regulatory bodies are implementing stringent noise control regulations, driving the demand for effective sound-absorbing solutions.

- Increasing Construction Activities: The construction industry is a major consumer of low-frequency sound-absorbing insulation materials. As urbanization and infrastructure development projects continue to surge worldwide, the demand for these materials in the construction sector is expected to grow significantly.

- Automotive Industry Growth: The automotive sector is another key market for low-frequency sound-absorbing insulation materials. As electric vehicles (EVs) gain popularity and consumer expectations for a quieter and more comfortable ride increase, the demand for these materials in the automotive industry is expected to rise.

- Technological Advancements: The development of advanced materials and manufacturing processes has led to the introduction of innovative low-frequency sound-absorbing insulation materials. These advancements offer improved performance, durability, and cost-effectiveness, driving their adoption in various applications.

- Sustainability and Environmental Concerns: Increasing environmental awareness and the demand for eco-friendly solutions have led to the development of sustainable low-frequency sound-absorbing insulation materials. These materials, often made from recycled or renewable sources, cater to the growing market demand for sustainable products.

Market Drivers

- Stringent Noise Control Regulations: Governments and regulatory bodies worldwide are implementing stringent noise control regulations, mandating the use of effective sound-absorbing solutions. This regulatory push is a significant driver for the low-frequency sound-absorbing insulation materials market.

- Rising Construction Activities: The global construction industry is experiencing substantial growth, fueled by urbanization, population growth, and infrastructure development. The need for noise control measures in buildings and infrastructure projects is driving the demand for low-frequency sound-absorbing insulation materials.

- Growing Automotive Industry: The automotive sector is witnessing rapid growth, driven by factors such as increasing vehicle production, rising disposable income, and changing consumer preferences. The demand for low-frequency sound-absorbing insulation materials in the automotive industry is fueled by the need for quieter and more comfortable vehicles.

- Awareness about Noise-Related Health Issues: The increasing awareness about the negative health effects of noise pollution has led to a greater demand for noise control solutions. Low-frequency sound-absorbing insulation materials help reduce noise levels, contributing to improved health and well-being.

- Technological Advancements: Advances in materials science and manufacturing technologies have led to the development of innovative low-frequency sound-absorbing insulation materials. These materials offer improved performance, durability, and cost-effectiveness, driving their adoption in various sectors.

Market Restraints

- High Costs: Low-frequency sound-absorbing insulation materials can be relatively expensive compared to conventional insulation materials. The higher costs associated with these specialized materials may limit their adoption, particularly in price-sensitive markets.

- Limited Awareness: Despite the growing awareness about noise pollution, there is still a lack of awareness among consumers and end-users about the benefits of low-frequency sound-absorbing insulation materials. This limited awareness can hinder market growth to some extent.

- Technological Challenges: Developing advanced low-frequency sound-absorbing insulation materials with optimal acoustic performance across a wide frequency range can pose technical challenges. Overcoming these challenges requires substantial research and development efforts.

- Regulatory Compliance: Compliance with various regulatory standards and certifications can be a complex process for manufacturers of low-frequency sound-absorbing insulation materials. Meeting these compliance requirements adds to the overall costs and may pose challenges for smaller players in the market.

- Competition from Existing Insulation Solutions: The low-frequency sound-absorbing insulation materials market faces competition from conventional insulation materials that also provide some level of sound absorption. This competition may impact the adoption of specialized sound-absorbing materials.

Market Opportunities

- Infrastructure Development Projects: The ongoing and planned infrastructure development projects worldwide provide significant growth opportunities for the low-frequency sound-absorbing insulation materials market. These projects include the construction of airports, railways, highways, and public buildings, all of which require effective noise control solutions.

- Renovation and Retrofitting Activities: The renovation and retrofitting of existing buildings and infrastructure present opportunities for the adoption of low-frequency sound-absorbing insulation materials. As older structures are upgraded to meet modern standards, there is a growing need for noise reduction measures.

- Sustainable Solutions: The increasing demand for sustainable and eco-friendly products creates opportunities for manufacturers of low-frequency sound-absorbing insulation materials. Developing materials with reduced environmental impact and improved energy efficiency can attract environmentally conscious consumers and businesses.

- Emerging Markets: Rapid urbanization and industrialization in emerging economies offer substantial growth potential for the low-frequency sound-absorbing insulation materials market. As these countries focus on infrastructure development, the demand for noise control solutions is expected to increase.

- Collaborations and Partnerships: Collaborations between insulation material manufacturers, acoustic consultants, and construction companies can lead to the development of integrated noise control solutions. Such partnerships can help drive innovation and expand market reach.

Market Dynamics

The Low-frequency Sound-absorbing Insulation Materials market is characterized by several dynamic factors that shape its growth and development. Key dynamics include changing regulatory landscape, technological advancements, market competition, and evolving customer preferences. These dynamics influence market trends, demand patterns, and the competitive landscape.

Regional Analysis

The Low-frequency Sound-absorbing Insulation Materials market is analyzed across various regions, including North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa. Each region has its own unique market dynamics, driven by factors such as economic growth, infrastructure development, regulatory environment, and consumer awareness. The regional analysis provides insights into the market size, growth potential, and key players in each region.

Competitive Landscape

Leading Companies in the Low-frequency Sound-absorbing Insulation Materials Market:

- Rockwool International A/S

- Owens Corning

- Saint-Gobain S.A.

- Knauf Insulation

- Kingspan Group plc

- Armacell International S.A.

- BASF SE

- Huntsman Corporation

- Johns Manville

- Recticel NV/SA

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The Low-frequency Sound-absorbing Insulation Materials market can be segmented based on material type, application, end-use industry, and region. Material types may include foam, fiberglass, mineral wool, recycled materials, and others. Applications can range from residential and commercial buildings to industrial facilities, transportation, and automotive sectors. End-use industries may include construction, transportation, automotive, aerospace, and others.

Category-wise Insights

- Foam-Based Materials: Foam-based low-frequency sound-absorbing insulation materials offer lightweight and versatile solutions for noise control. They are widely used in building construction, automotive interiors, and industrial applications.

- Fiberglass Insulation: Fiberglass insulation materials provide excellent thermal and acoustic performance. They are commonly used in residential and commercial buildings, HVAC systems, and industrial settings.

- Mineral Wool: Mineral wool insulation materials offer high sound absorption capabilities and fire resistance. They find applications in buildings, power plants, and industrial facilities.

- Recycled Materials: Low-frequency sound-absorbing insulation materials made from recycled materials cater to the growing demand for sustainable solutions. These materials offer environmental benefits and can be used in various applications.

Key Benefits for Industry Participants and Stakeholders

- Improved Acoustic Performance: Low-frequency sound-absorbing insulation materials help reduce noise levels and improve acoustic comfort in various settings, enhancing the well-being and productivity of occupants.

- Regulatory Compliance: By using low-frequency sound-absorbing insulation materials, industry participants can comply with noise control regulations and standards, avoiding penalties and ensuring a safe and comfortable environment.

- Enhanced Energy Efficiency: Some low-frequency sound-absorbing insulation materials offer additional benefits such as thermal insulation, contributing to energy efficiency and reducing heating and cooling costs.

- Differentiation and Competitive Advantage: Companies that offer innovative low-frequency sound-absorbing insulation materials can differentiate themselves in the market and gain a competitive advantage by providing effective noise control solutions to their customers.

- Sustainability and Environmental Responsibility: Manufacturers and users of low-frequency sound-absorbing insulation materials can showcase their commitment to sustainability and environmental responsibility by using eco-friendly and recycled materials.

SWOT Analysis

Strengths:

- Effective noise reduction capabilities

- Technological advancements and innovation

- Growing demand for noise control solutions

Weaknesses:

- High costs compared to conventional insulation materials

- Limited awareness among consumers and end-users

- Technical challenges in developing optimal acoustic performance

Opportunities:

- Infrastructure development projects

- Renovation and retrofitting activities

- Sustainable and eco-friendly solutions

Threats:

- Competition from conventional insulation materials

- Stringent regulatory compliance requirements

- Economic uncertainties and market volatility

Market Key Trends

- Rising Demand for Acoustic Comfort: Increasing awareness about the negative impact of noise pollution on human health and well-being is driving the demand for low-frequency sound-absorbing insulation materials. Consumers and businesses are seeking acoustic comfort solutions in various settings.

- Integration of Smart Technologies: The integration of smart technologies, such as Internet of Things (IoT) and artificial intelligence (AI), is enabling the development of intelligent sound-absorbing materials. These materials can automatically adjust their properties to optimize noise control based on real-time conditions.

- Focus on Sustainable Solutions: There is a growing emphasis on sustainable and eco-friendly products in the low-frequency sound-absorbing insulation materials market. Manufacturers are developing materials with reduced environmental impact, recyclability, and energy efficiency.

- Customization and Design Flexibility: Customers are increasingly demanding customized low-frequency sound-absorbing insulation solutions that align with their specific requirements. Manufacturers are focusing on offering design flexibility and customization options to cater to these demands.

Covid-19 Impact

The Covid-19 pandemic has had a significant impact on the Low-frequency Sound-absorbing Insulation Materials market. The construction industry, one of the key end-use industries for these materials, experienced disruptions due to lockdowns, supply chain disruptions, and labor shortages. However, the pandemic also highlighted the importance of noise control and indoor acoustic comfort, leading to increased demand for low-frequency sound-absorbing insulation materials in healthcare facilities, offices, and residential buildings. The market witnessed a shift in demand towards materials that provide both acoustic performance and antimicrobial properties to ensure safer and healthier environments.

Key Industry Developments

- Introduction of Sustainable Materials: Manufacturers are increasingly focusing on developing low-frequency sound-absorbing insulation materials using sustainable and recycled materials. These materials help address environmental concerns and cater to the growing demand for eco-friendly solutions.

- Technological Advancements: Ongoing research and development efforts have led to the introduction of advanced materials with improved acoustic performance. These materials offer enhanced sound absorption capabilities across a wide frequency range.

- Collaboration with Acoustic Consultants: Insulation material manufacturers are collaborating with acoustic consultants to develop integrated noise control solutions. These collaborations help optimize the performance of low-frequency sound-absorbing insulation materials in various applications.

- Market Expansion in Emerging Economies: Several key players in the low-frequency sound-absorbing insulation materials market are focusing on expanding their presence in emerging economies. These regions offer significant growth potential due to rapid urbanization and infrastructure development.

Analyst Suggestions

- Continuous Research and Development: Manufacturers should invest in research and development activities to develop innovative low-frequency sound-absorbing insulation materials with improved acoustic performance, sustainability, and cost-effectiveness.

- Marketing and Awareness Campaigns: Increasing awareness among consumers and end-users about the benefits of low-frequency sound-absorbing insulation materials is crucial. Manufacturers should engage in marketing and awareness campaigns to educate the market about the importance of noise control and the advantages of these materials.

- Collaboration and Partnerships: Collaboration with acoustic consultants, construction companies, and other stakeholders can help manufacturers develop integrated noise control solutions and expand their market reach.

- Adapting to Regulatory Changes: The regulatory landscape for noise control is continuously evolving. Manufacturers should stay updated on the latest regulations and standards and ensure their products comply with the requirements.

- Focus on Sustainability: Considering the growing demand for sustainable solutions, manufacturers should prioritize the development of low-frequency sound-absorbing insulation materials that are environmentally friendly, recyclable, and energy efficient.

Future Outlook

The future outlook for the Low-frequency Sound-absorbing Insulation Materials market is promising. The market is expected to witness steady growth driven by factors such as increasing awareness about noise pollution, stringent regulations, infrastructure development, and technological advancements. The demand for innovative and sustainable low-frequency sound-absorbing insulation materials is likely to rise as customers seek effective noise control solutions. The market is also expected to witness collaborations, partnerships, and mergers and acquisitions as companies strive to expand their product offerings and global presence.

Conclusion

The Low-frequency Sound-absorbing Insulation Materials market is a niche segment within the broader insulation materials industry, catering to the growing demand for noise control solutions. The market offers several opportunities driven by infrastructure development projects, renovation activities, and the demand for sustainable solutions. However, challenges such as high costs and limited awareness need to be addressed. Manufacturers should focus on innovation, sustainability, and customization to stay competitive in the market. The future outlook for the market is positive, with steady growth expected in the coming years.