444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The laser marking equipment market has emerged as a cornerstone of modern manufacturing and identification processes. This market facilitates precise, permanent marking on various materials, providing industries with a reliable means to enhance product traceability, branding, and security. As industries worldwide seek more efficient and sophisticated marking solutions, the laser marking equipment market’s growth trajectory remains impressive.

Meaning

Laser marking equipment is a technology that utilizes laser beams to create marks on surfaces, often by altering the material’s appearance or composition. This non-contact method ensures high precision, durability, and resistance to wear and tear. In industries ranging from electronics to automotive, laser marking equipment enables intricate designs, serial numbers, barcodes, and other essential information to be etched onto products efficiently.

Executive Summary

The laser marking equipment market is undergoing robust expansion due to its indispensable role in modern manufacturing. This comprehensive report delves into the core market insights, driving forces, constraints, opportunities, and prevailing trends. It offers a profound regional analysis, an assessment of the competitive landscape, and projections for the market’s future. Moreover, the report examines the impact of the Covid-19 pandemic and furnishes valuable recommendations for industry players to thrive in this evolving landscape.

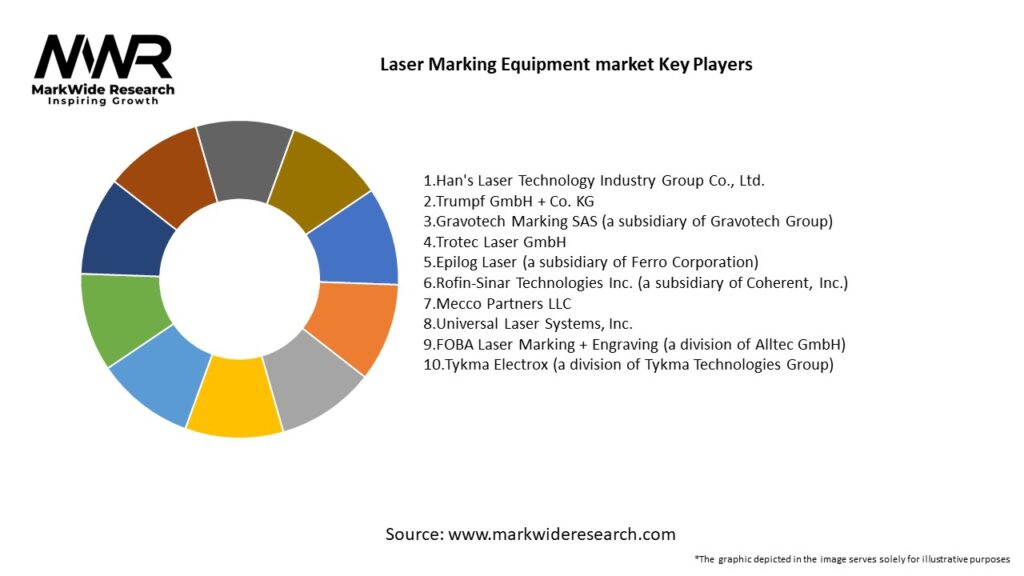

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

The growth of the Laser Marking Equipment market is influenced by several key drivers:

Market Restraints

Despite the positive growth prospects, there are several challenges facing the Laser Marking Equipment market:

Market Opportunities

The Laser Marking Equipment market presents various growth opportunities:

Market Dynamics

The Laser Marking Equipment market is influenced by various factors, including:

Regional Analysis

The Laser Marking Equipment market exhibits regional variations in adoption rates and technological advancements:

Competitive Landscape

Leading Companies in the Laser Marking Equipment Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The Laser Marking Equipment market can be segmented based on various factors, including:

Category-wise Insights

Each category of laser marking solutions offers unique benefits for specific applications:

Key Benefits for Industry Participants and Stakeholders

Laser Marking Equipment offers several benefits for stakeholders:

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Key trends shaping the Laser Marking Equipment market include:

Covid-19 Impact

The Covid-19 pandemic had varying effects on the laser marking equipment market. While supply chain disruptions initially posed challenges, the market demonstrated resilience due to its essential role in diverse industries. The pandemic underscored the importance of traceability and anti-counterfeiting measures, further driving the adoption of laser marking solutions.

Key Industry Developments

Analyst Suggestions

Future Outlook

The future outlook for the laser marking equipment market is positive, with sustained growth projected across industries. The market’s evolution will be guided by advancements in laser technology, increasing demand for traceability, and the ongoing convergence of digital and physical processes. Market players should embrace change, stay attuned to emerging trends, and adapt their strategies accordingly.

The market’s journey has been marked by continuous innovation, resulting in a range of solutions that cater to specific applications and materials. From the integration of AI and IoT to the development of handheld devices, the industry’s response to evolving demands is commendable. The Covid-19 pandemic highlighted the resilience of the market, reaffirming the significance of traceability in supply chains.

Conclusion

The laser marking equipment market serves as an essential enabler of modern manufacturing, offering accurate, permanent, and versatile marking solutions. As industries continue to prioritize traceability, branding, and efficiency, the market is poised for substantial growth. By embracing innovation, collaboration, and adaptability, industry participants can harness the potential of the laser marking equipment market and contribute to its continued evolution.

In conclusion, the laser marking equipment market stands as a testament to the fusion of technology and industrial needs. With its unparalleled precision and versatility, laser marking has redefined product identification and traceability across diverse sectors. As manufacturers strive for efficiency, quality, and compliance, laser marking equipment emerges as an indispensable tool.

What is Laser Marking Equipment?

Laser marking equipment refers to devices that use laser technology to engrave, etch, or mark materials with precision. This equipment is widely used in various industries for product identification, branding, and traceability.

What are the key players in the Laser Marking Equipment market?

Key players in the Laser Marking Equipment market include companies like Trumpf, Epilog Laser, and Trotec Laser, which are known for their innovative solutions and extensive product ranges in laser marking technology, among others.

What are the main drivers of growth in the Laser Marking Equipment market?

The growth of the Laser Marking Equipment market is driven by the increasing demand for automation in manufacturing, the need for high-quality marking solutions, and the rising adoption of laser technology in various sectors such as automotive, electronics, and packaging.

What challenges does the Laser Marking Equipment market face?

Challenges in the Laser Marking Equipment market include the high initial investment costs associated with advanced laser systems and the need for skilled operators to manage and maintain the equipment effectively.

What opportunities exist in the Laser Marking Equipment market?

Opportunities in the Laser Marking Equipment market include the expansion of e-commerce, which requires efficient product labeling, and the growing trend of personalized products that necessitate unique marking solutions.

What trends are shaping the Laser Marking Equipment market?

Trends in the Laser Marking Equipment market include the development of more compact and versatile laser systems, the integration of artificial intelligence for enhanced precision, and the increasing focus on eco-friendly marking solutions.

Laser Marking Equipment market

| Segmentation Details | Description |

|---|---|

| Product Type | Fiber Laser, CO2 Laser, UV Laser, Green Laser |

| End User | Automotive OEMs, Electronics Manufacturers, Aerospace, Medical Device Companies |

| Technology | Marking, Engraving, Coding, Etching |

| Application | Labeling, Serialization, Traceability, Branding |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Laser Marking Equipment Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at