444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

The global coil wound devices market is a rapidly growing sector within the electrical industry. Coil wound devices are widely used in various applications, including power generation, automotive, aerospace, consumer electronics, and industrial machinery. These devices play a crucial role in converting electrical energy into mechanical energy and vice versa. The market for coil wound devices is driven by the increasing demand for energy-efficient solutions, advancements in technology, and the growing automation industry.

Coil wound devices, also known as electromagnetic devices, consist of a coil or winding that is wound around a core material. The coil is typically made of copper or aluminum wire, which is wound in a specific pattern to create a magnetic field when an electric current passes through it. This magnetic field enables the device to perform its intended function, such as generating electromagnetic force, converting electrical energy into mechanical energy, or vice versa. Coil wound devices encompass a wide range of products, including transformers, inductors, solenoids, and electromagnets.

Executive Summary

The global coil wound devices market has witnessed significant growth in recent years and is expected to continue its upward trajectory. The market is driven by the increasing demand for energy-efficient devices, the rapid growth of the automotive and consumer electronics industries, and advancements in technology. Key market players are focusing on research and development activities to introduce innovative products that cater to the evolving needs of various industries. However, the market also faces challenges such as price volatility of raw materials and intense competition among manufacturers.

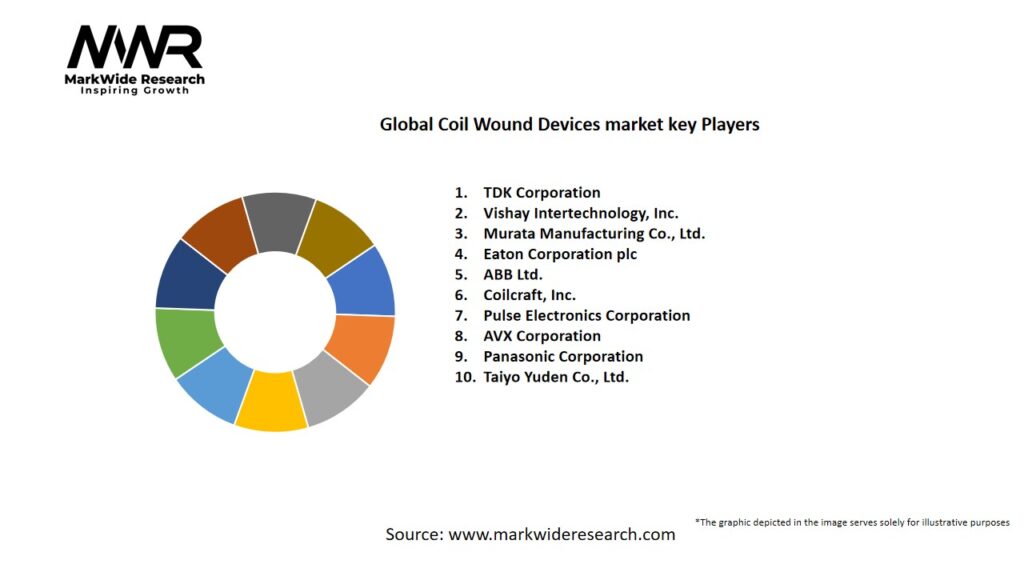

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

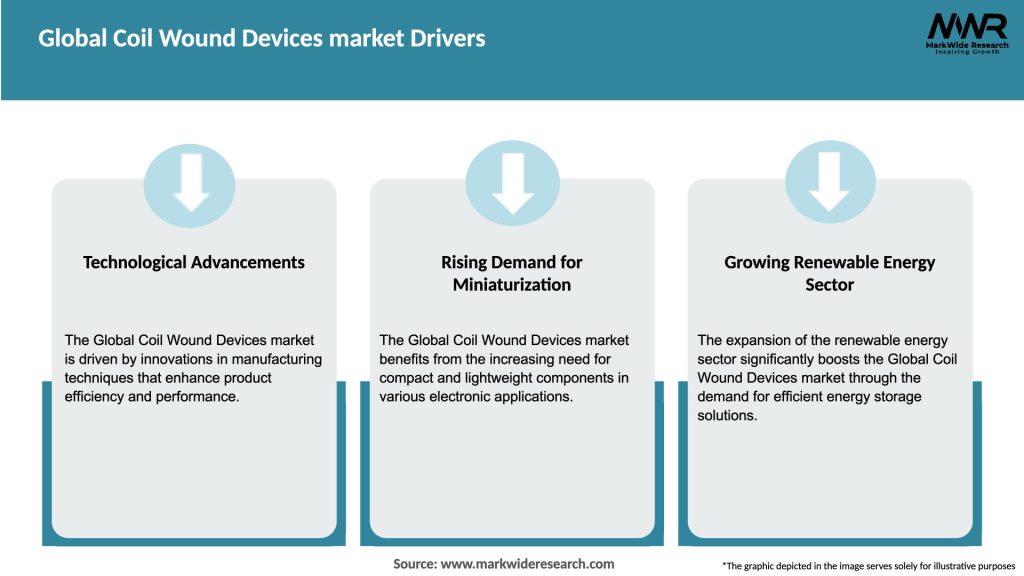

Several factors are driving the growth of the global coil wound devices market:

Market Restraints

Despite the positive growth prospects, the global coil wound devices market faces certain challenges that may hinder its progress:

Market Opportunities

The global coil wound devices market presents several opportunities for growth and expansion:

Market Dynamics

The global coil wound devices market is influenced by various dynamics, including industry trends, regulatory factors, technological advancements, and consumer preferences. Understanding these dynamics is crucial for manufacturers to make informed business decisions and adapt to the evolving market landscape.

One significant trend in the coil wound devices market is the increasing adoption of lightweight and compact designs. Manufacturers are focusing on developing smaller and lighter coil wound devices without compromising on performance. This trend is driven by the demand for portable and space-constrained applications in sectors such as automotive, aerospace, and consumer electronics.

Another trend is the integration of smart features in coil wound devices. With the rise of the IoT and industry 4.0, there is a growing need for intelligent and connected devices. Coil wound devices with built-in sensors, digital control systems, and communication capabilities enable remote monitoring, predictive maintenance, and enhanced functionality.

Regulatory factors also influence the market dynamics of coil wound devices. Government regulations aimed at energy efficiency, safety standards, and environmental protection impact the design, manufacturing, and usage of these devices. Compliance with regulatory requirements is essential for manufacturers to ensure market acceptance and avoid legal issues.

Technological advancements play a vital role in shaping the market dynamics of coil wound devices. Manufacturers are continuously investing in research and development to improve the efficiency, reliability, and performance of these devices. Advancements in materials, such as amorphous alloys and nanocrystalline cores, contribute to higher energy efficiency and reduced losses in coil wound devices.

Consumer preferences and industry-specific requirements drive the demand for specific types of coil wound devices. For example, the automotive industry demands coil wound devices with high-temperature resistance and compact designs, while the renewable energy sector requires devices capable of handling high voltage and power levels.

The global coil wound devices market is also influenced by economic factors, such as GDP growth, industrial output, and investment patterns. Economic fluctuations and changes in consumer spending can impact the demand for coil wound devices in different industry sectors.

Regional Analysis

The global coil wound devices market is segmented into various regions, including North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa. Each region has its unique characteristics and market dynamics.

Competitive Landscape

Leading companies in the Global Coil Wound Devices market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

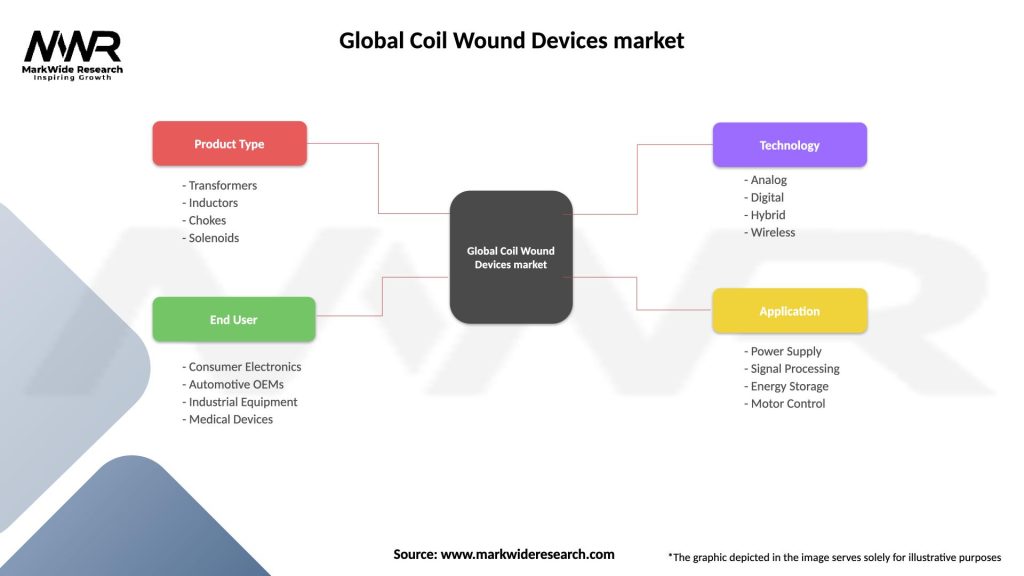

The global coil wound devices market can be segmented based on product type, application, and end-use industry.

Product Type:

Application:

End-Use Industry:

Category-wise Insights

Transformers: Transformers are the most widely used coil wound devices, primarily in power generation, distribution, and various industrial applications. These devices play a crucial role in stepping up or stepping down voltage levels for efficient power transmission and distribution. The demand for transformers is driven by the growing power generation capacity, increasing infrastructure development, and expanding renewable energy projects globally.

Inductors: Inductors are coil wound devices used for energy storage, filtering, and impedance matching applications. They are widely used in electronic circuits, power supplies, and automotive electronics. The demand for inductors is fueled by the increasing use of electronic devices, the growth of the automotive industry, and the adoption of renewable energy systems.

Solenoids: Solenoids are electromagnetic devices that convert electrical energy into linear motion. They find applications in various industries, including automotive, healthcare, industrial automation, and consumer electronics. Solenoids are used in applications such as valves, locks, actuators, and relays. The growing automotive sector, rising automation, and the need for precise control systems contribute to the demand for solenoids.

Electromagnets: Electromagnets are coil wound devices that generate a magnetic field when an electric current passes through them. They are used in applications such as lifting and holding heavy objects, magnetic separation, and magnetic resonance imaging (MRI) systems. The demand for electromagnets is driven by industries such as manufacturing, healthcare, and automotive.

Others: The “others” category includes various coil wound devices that are specific to certain applications or industries. These devices may include magnetic sensors, chokes, relays, and voice coil motors. The demand for these devices depends on the specific requirements of niche applications and industries.

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The global coil wound devices market, like many other industries, has been affected by the COVID-19 pandemic. The pandemic led to disruptions in the global supply chain, reduced manufacturing activities, and a decline in demand for various products and services.

During the initial phases of the pandemic, many manufacturing facilities were temporarily shut down or operated at reduced capacities to comply with lockdown measures and ensure employee safety. This resulted in delays in production and supply chain disruptions, impacting the availability of coil wound devices.

The demand for coil wound devices was also affected by the economic slowdown caused by the pandemic. Industries such as automotive, aerospace, and consumer electronics experienced a decline in demand due to reduced consumer spending and disrupted supply chains. This, in turn, affected the demand for coil wound devices used in these sectors.

However, the pandemic also highlighted the importance of certain applications that rely on coil wound devices. For instance, the need for renewable energy sources and the expansion of remote working and communication technologies created opportunities for the coil wound devices market. The shift towards remote monitoring and automation in various industries also drove the demand for smart coil wound devices.

As the global economy recovers and industries regain momentum, the coil wound devices market is expected to rebound. The increasing focus on energy efficiency, sustainability, and technological advancements will likely drive the market’s recovery and future growth.

Key Industry Developments

Analyst Suggestions

Future Outlook

The future of the global coil wound devices market looks promising, driven by factors such as the increasing demand for energy-efficient solutions, advancements in technology, and the growing adoption of automation across industries. As industries continue to emphasize energy conservation, sustainability, and improved performance, the demand for high-quality coil wound devices will increase. Technological advancements, including the integration of smart features and the development of advanced materials, will shape the future of coil wound devices. The market is expected to witness further miniaturization, lightweight designs, and enhanced functionality to meet the requirements of emerging applications such as IoT, electric mobility, and automation systems.

In conclusion, the global coil wound devices market is poised for growth, driven by the demand for energy-efficient solutions, advancements in technology, and the increasing adoption of automation. Manufacturers that focus on innovation, sustainability, and strategic partnerships will be well-positioned to capitalize on these opportunities and thrive in the competitive landscape.

What is Coil Wound Devices?

Coil wound devices are electrical components that utilize wound coils to create magnetic fields, which are essential in various applications such as transformers, inductors, and motors.

What are the key players in the Global Coil Wound Devices market?

Key players in the Global Coil Wound Devices market include companies like Coilcraft, Vishay Intertechnology, and Würth Elektronik, among others.

What are the main drivers of growth in the Global Coil Wound Devices market?

The growth of the Global Coil Wound Devices market is driven by the increasing demand for energy-efficient solutions, advancements in automotive electronics, and the rising adoption of renewable energy technologies.

What challenges does the Global Coil Wound Devices market face?

Challenges in the Global Coil Wound Devices market include the high cost of raw materials, competition from alternative technologies, and the need for continuous innovation to meet evolving industry standards.

What opportunities exist in the Global Coil Wound Devices market?

Opportunities in the Global Coil Wound Devices market include the expansion of electric vehicles, the growth of smart grid technologies, and the increasing integration of IoT devices in various sectors.

What trends are shaping the Global Coil Wound Devices market?

Trends in the Global Coil Wound Devices market include the miniaturization of components, the development of wireless charging technologies, and the increasing focus on sustainable manufacturing practices.

Global Coil Wound Devices market

| Segmentation Details | Description |

|---|---|

| Product Type | Transformers, Inductors, Chokes, Solenoids |

| End User | Consumer Electronics, Automotive OEMs, Industrial Equipment, Medical Devices |

| Technology | Analog, Digital, Hybrid, Wireless |

| Application | Power Supply, Signal Processing, Energy Storage, Motor Control |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the Global Coil Wound Devices market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at