444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

The dispensing pharmacy packaging machine market is experiencing significant growth due to the rising demand for efficient and accurate pharmaceutical packaging solutions. These machines play a crucial role in automating the process of packaging medications in pharmacies, ensuring precision, speed, and adherence to regulatory standards. With the increasing focus on patient safety, convenience, and minimizing errors in medication distribution, the market for dispensing pharmacy packaging machines is expected to witness substantial expansion in the coming years.

Dispensing pharmacy packaging machines are advanced automated systems designed to handle the packaging of pharmaceutical products in pharmacies. These machines offer a range of functionalities, including counting, sorting, labeling, and blister packaging. By automating these tasks, they streamline the pharmacy workflow, reduce manual errors, enhance medication accuracy, and improve operational efficiency.

Executive Summary

The global market for dispensing pharmacy packaging machines is poised for remarkable growth in the forecast period. The market is driven by the increasing demand for efficient and error-free medication packaging solutions, growing adoption of automation in pharmacies, and the need to comply with stringent regulatory guidelines. These machines offer numerous benefits such as improved inventory management, reduced medication waste, enhanced patient safety, and increased productivity. Key players in the market are focusing on technological advancements, product innovation, and strategic collaborations to strengthen their market position.

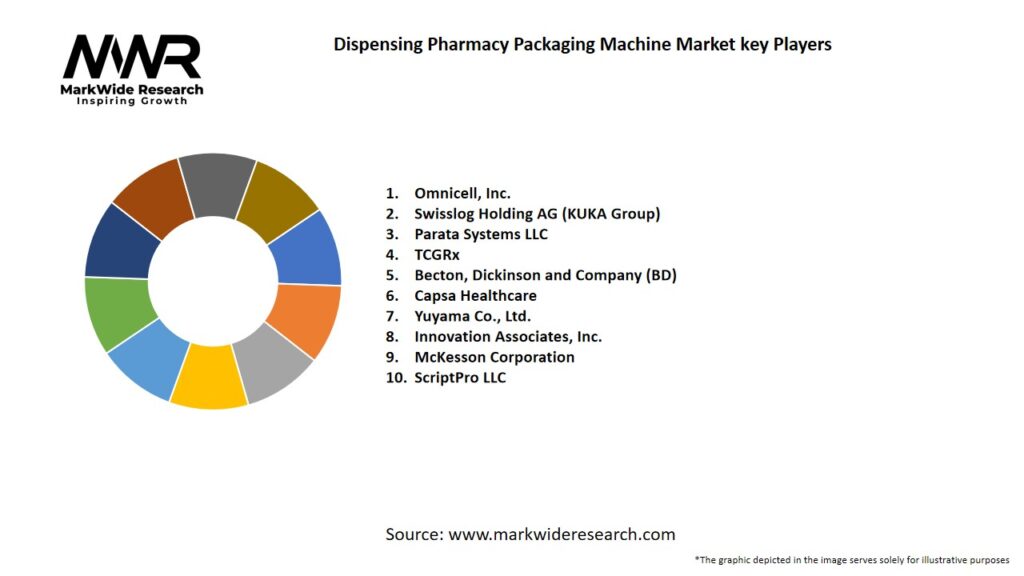

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The dispensing pharmacy packaging machine market is driven by various dynamics, including technological advancements, regulatory compliance, market competition, and changing consumer preferences.

Technological advancements play a crucial role in shaping the market landscape. Manufacturers are continually investing in research and development to enhance the functionalities of dispensing pharmacy packaging machines. Integration of advanced technologies such as AI, machine learning, robotics, and IoT enables improved efficiency, accuracy, and automation.

Regulatory compliance is a key driver, as pharmaceutical packaging must adhere to stringent guidelines to ensure patient safety and product integrity. Manufacturers need to stay updated with regulatory changes and design machines that meet the evolving requirements.

Market competition drives innovation and product differentiation. Key players focus on developing machines with user-friendly interfaces, high-speed operation, customization options, and integration with other pharmacy management systems. This competitive environment benefits end-users by providing them with a wide range of options to choose from.

Changing consumer preferences also impact the market dynamics. Patients and healthcare providers are increasingly seeking convenient and error-free medication packaging solutions. This drives the demand for dispensing pharmacy packaging machines that offer features like multi-dose packaging, barcode scanning, and patient-specific labeling.

Regional Analysis

The global dispensing pharmacy packaging machine market can be segmented into several regions, including North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa.

Competitive Landscape

Leading Companies in the Dispensing Pharmacy Packaging Machine Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

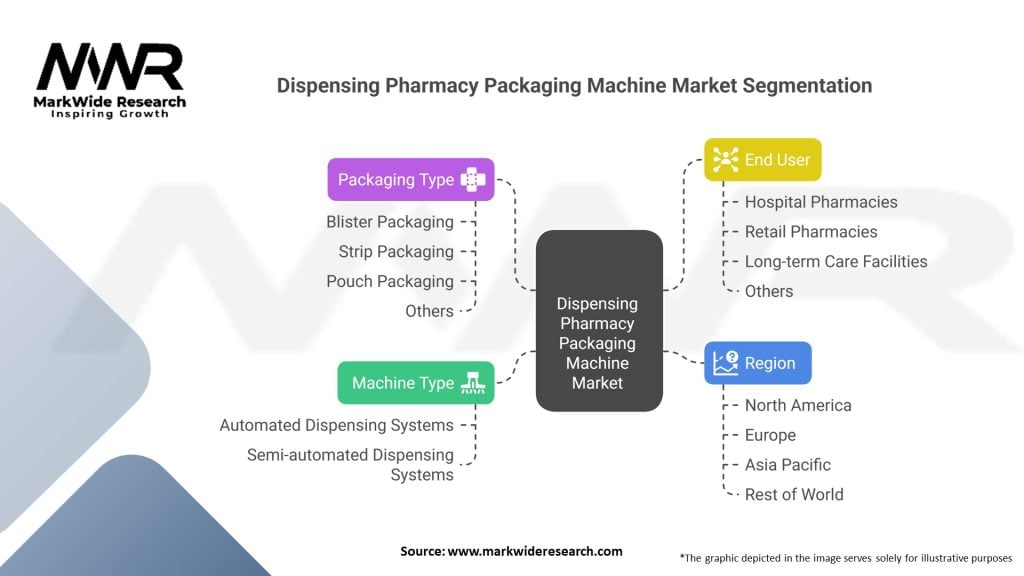

Segmentation

The dispensing pharmacy packaging machine market can be segmented based on various factors, including machine type, packaging type, end-user, and region.

Segmentation allows manufacturers and stakeholders to identify specific market segments and tailor their strategies accordingly. It helps them understand the varying needs and preferences of different end-users and regions, leading to better decision-making and market positioning.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

Industry participants and stakeholders in the dispensing pharmacy packaging machine market can enjoy several key benefits:

SWOT Analysis

A SWOT (Strengths, Weaknesses, Opportunities, and Threats) analysis of the dispensing pharmacy packaging machine market provides a comprehensive understanding of its internal and external factors.

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

The dispensing pharmacy packaging machine market is influenced by several key trends:

Covid-19 Impact

The Covid-19 pandemic has significantly influenced the dispensing pharmacy packaging machine market:

Key Industry Developments

The dispensing pharmacy packaging machine market has witnessed several key industry developments:

Analyst Suggestions

Based on market trends and developments, analysts provide the following suggestions:

Future Outlook

The future of the dispensing pharmacy packaging machine market appears promising. Key factors shaping the market’s outlook include:

Conclusion

Increased Collaboration and Partnerships: Collaboration between manufacturers, software providers, and pharmaceutical companies will intensify. This collaboration will lead to the development of integrated solutions that seamlessly connect dispensing pharmacy packaging machines with other pharmacy management systems, optimizing workflow and data management. Focus on Data Analytics and Insights: The collection and analysis of data generated by dispensing pharmacy packaging machines will become increasingly important. Manufacturers and pharmacies will utilize data analytics to gain insights into medication trends, optimize inventory management, and enhance operational efficiency.

Emphasis on Sustainability and Green Packaging: Sustainability will continue to be a significant trend in the pharmaceutical industry, driving the demand for eco-friendly and green packaging solutions. Manufacturers will develop packaging materials and machines that minimize waste, reduce carbon footprint, and support sustainable practices. Adoption of Remote Monitoring and Predictive Maintenance: Remote monitoring and predictive maintenance capabilities will become standard features in dispensing pharmacy packaging machines. These capabilities will enable manufacturers to remotely diagnose and resolve issues, ensuring minimal downtime and maximizing machine performance.

In conclusion, the dispensing pharmacy packaging machine market is poised for significant growth in the coming years. Technological advancements, increasing focus on patient safety, regulatory compliance, and sustainability will shape the market. Manufacturers that adapt to these trends, collaborate with stakeholders, and provide innovative and customizable solutions will be well-positioned to capitalize on the market opportunities and drive success in the industry.

What is Dispensing Pharmacy Packaging Machine?

A Dispensing Pharmacy Packaging Machine is a device used in pharmacies to automate the packaging of medications. These machines enhance efficiency by accurately dispensing and packaging various pharmaceutical products, ensuring proper dosage and compliance with safety standards.

What are the key players in the Dispensing Pharmacy Packaging Machine market?

Key players in the Dispensing Pharmacy Packaging Machine market include Omnicell, Inc., BD (Becton, Dickinson and Company), and Parata Systems, LLC, among others. These companies are known for their innovative solutions and technologies in pharmacy automation.

What are the growth factors driving the Dispensing Pharmacy Packaging Machine market?

The growth of the Dispensing Pharmacy Packaging Machine market is driven by the increasing demand for automation in pharmacies, the rising need for medication adherence, and the growing complexity of medication regimens. Additionally, the expansion of retail pharmacy chains is contributing to market growth.

What challenges does the Dispensing Pharmacy Packaging Machine market face?

The Dispensing Pharmacy Packaging Machine market faces challenges such as high initial investment costs and the need for regular maintenance. Furthermore, the integration of these machines with existing pharmacy systems can be complex and may require significant training.

What opportunities exist in the Dispensing Pharmacy Packaging Machine market?

Opportunities in the Dispensing Pharmacy Packaging Machine market include advancements in technology, such as artificial intelligence and machine learning, which can enhance machine efficiency. Additionally, the growing trend of personalized medicine presents new avenues for tailored packaging solutions.

What trends are shaping the Dispensing Pharmacy Packaging Machine market?

Current trends in the Dispensing Pharmacy Packaging Machine market include the increasing adoption of robotic systems for medication dispensing and the integration of smart technology for real-time monitoring. There is also a focus on sustainability, with manufacturers exploring eco-friendly packaging materials.

Dispensing Pharmacy Packaging Machine Market:

| Segmentation | Details |

|---|---|

| Machine Type | Automated Dispensing Systems, Semi-automated Dispensing Systems |

| Packaging Type | Blister Packaging, Strip Packaging, Pouch Packaging, Others |

| End User | Hospital Pharmacies, Retail Pharmacies, Long-term Care Facilities, Others |

| Region | North America, Europe, Asia Pacific, Rest of World |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Dispensing Pharmacy Packaging Machine Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at