444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Direct-to-Shape inkjet printers have emerged as a groundbreaking technology in the printing industry, offering unprecedented capabilities and versatility. This advanced printing solution allows for direct printing on various three-dimensional objects, eliminating the need for traditional labeling or pre-printed materials. This comprehensive market analysis provides insights into the direct-to-shape inkjet printers market, including key trends, market drivers, restraints, opportunities, and future outlook.

Direct-to-shape inkjet printers are innovative machines that enable printing directly on complex surfaces such as bottles, containers, cans, and other shaped objects. This revolutionary technology utilizes inkjet printheads to precisely deposit ink onto the surface, resulting in vibrant, high-resolution graphics. By eliminating the need for labels or pre-printed materials, direct-to-shape inkjet printers offer cost-effective and customizable printing solutions for a wide range of industries.

Executive Summary

The direct-to-shape inkjet printers market has witnessed significant growth in recent years due to the increasing demand for personalized packaging, brand differentiation, and the need for efficient printing processes. This executive summary provides a concise overview of the market, highlighting key market insights, market drivers, restraints, opportunities, and future prospects for industry participants and stakeholders.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

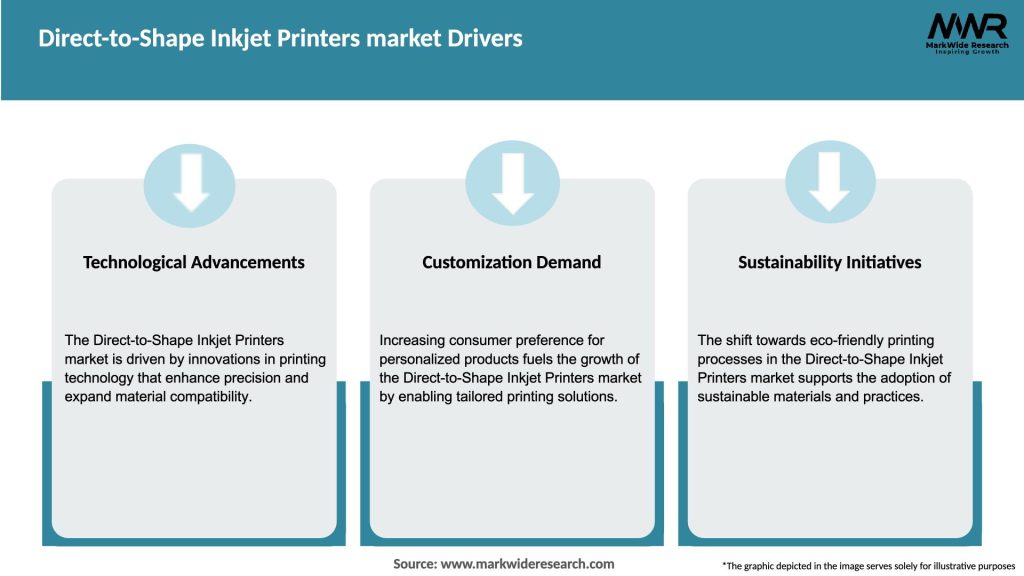

The direct-to-shape inkjet printers market is driven by a combination of factors, including market drivers, restraints, and opportunities. The market dynamics shape the competitive landscape and influence the growth and direction of the industry. Understanding these dynamics is essential for industry participants to make informed decisions and capitalize on the market’s potential.

Regional Analysis

The direct-to-shape inkjet printers market exhibits regional variations in terms of adoption, demand, and market trends. This section provides a comprehensive analysis of the market across different regions, including North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa. It explores the factors influencing market growth in each region and highlights the key market players operating in these geographies.

Competitive Landscape

Leading Companies in the Direct-to-Shape Inkjet Printers Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The direct-to-shape inkjet printers market can be segmented based on various factors such as technology type, substrate type, end-use industry, and geography. This segmentation allows for a deeper understanding of the market dynamics within specific segments, enabling businesses to target their products and services to the right audience effectively.

Category-wise Insights

This section provides in-depth insights into the direct-to-shape inkjet printers market based on different categories, including printer type, ink type, application, and end-use industry. It examines the market trends, growth potential, and opportunities within each category, helping industry participants identify key growth areas and make strategic decisions accordingly.

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

This section highlights the key trends shaping the direct-to-shape inkjet printers market. It covers technological advancements, market innovations, changing consumer preferences, and industry developments. By staying updated with the latest trends, industry participants can adapt their strategies and offerings to align with market demands and stay ahead of the competition.

Covid-19 Impact

The Covid-19 pandemic has had a significant impact on various industries, including printing. This section examines the effects of the pandemic on the direct-to-shape inkjet printers market. It analyzes the disruptions caused by supply chain disruptions, changing consumer behavior, and market dynamics. Furthermore, it explores the market’s response to the crisis, including innovations, strategies, and recovery measures adopted by industry participants.

Key Industry Developments

This section highlights the key industry developments in the direct-to-shape inkjet printers market. It covers product launches, mergers and acquisitions, partnerships and collaborations, and other notable activities that have shaped the market landscape. These developments reflect the dynamic nature of the industry and provide insights into the strategies employed by market players to gain a competitive edge and drive market growth.

Analyst Suggestions

Based on the comprehensive analysis of the direct-to-shape inkjet printers market, our industry experts offer valuable suggestions for industry participants and stakeholders. These suggestions encompass strategies for market entry, product development, partnerships, and marketing tactics to maximize growth opportunities and navigate challenges effectively. The suggestions provide actionable insights to help businesses make informed decisions and thrive in the competitive market landscape.

Future Outlook

The future outlook section presents a forward-looking view of the direct-to-shape inkjet printers market. It explores emerging trends, technological advancements, market growth potential, and anticipated market dynamics. This section assists industry participants in understanding the market’s future prospects and devising strategies to capitalize on upcoming opportunities.

Conclusion

The direct-to-shape inkjet printers market is witnessing remarkable growth driven by the demand for customized packaging, cost efficiency, and advancements in printing technology. While initial capital investment and technical limitations pose challenges, emerging markets and the integration of IoT present significant growth opportunities.

Industry participants and stakeholders can benefit from understanding regional dynamics, competitive landscape, market segmentation, and key trends to make informed decisions and stay competitive in the evolving market. By embracing innovation, leveraging partnerships, and adapting to market changes, businesses can harness the potential of direct-to-shape inkjet printers and revolutionize the printing industry.

What is Direct-to-Shape Inkjet Printers?

Direct-to-Shape Inkjet Printers are specialized printing devices designed to print directly onto three-dimensional objects, such as bottles, cans, and other packaging materials. They utilize inkjet technology to achieve high-quality, detailed prints on various surfaces.

What are the key companies in the Direct-to-Shape Inkjet Printers market?

Key companies in the Direct-to-Shape Inkjet Printers market include Markem-Imaje, Domino Printing Sciences, and Epson, among others. These companies are known for their innovative printing solutions and advanced technology in the packaging and labeling sectors.

What are the drivers of growth in the Direct-to-Shape Inkjet Printers market?

The growth of the Direct-to-Shape Inkjet Printers market is driven by the increasing demand for customized packaging solutions, the rise of e-commerce, and the need for efficient production processes. Additionally, advancements in inkjet technology are enhancing print quality and speed.

What challenges does the Direct-to-Shape Inkjet Printers market face?

The Direct-to-Shape Inkjet Printers market faces challenges such as high initial investment costs and the need for specialized training for operators. Furthermore, competition from traditional printing methods can hinder market penetration.

What opportunities exist in the Direct-to-Shape Inkjet Printers market?

Opportunities in the Direct-to-Shape Inkjet Printers market include the expansion into new industries such as cosmetics and pharmaceuticals, where unique packaging is essential. Additionally, the growing trend of sustainable packaging solutions presents new avenues for innovation.

What trends are shaping the Direct-to-Shape Inkjet Printers market?

Trends in the Direct-to-Shape Inkjet Printers market include the increasing adoption of automation and digitalization in manufacturing processes. There is also a growing focus on eco-friendly inks and materials, reflecting the industry’s shift towards sustainability.

Direct-to-Shape Inkjet Printers Market

| Segmentation | Details |

|---|---|

| Printing Technology | UV-Curable Inkjet, Solvent-based Inkjet, Others |

| Application | Food & Beverage Packaging, Personal Care Packaging, Pharmaceuticals Packaging, Others |

| Region | North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Direct-to-Shape Inkjet Printers Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at