444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

Automated Guided Vehicles (AGVs) have revolutionized the material handling and logistics industry, providing efficient and autonomous transportation of goods within various sectors. AGVs are self-operating vehicles that navigate through predetermined paths or routes without the need for human intervention. These vehicles are equipped with advanced sensors, cameras, and navigation systems to ensure precise and safe movement.

The global Automated Guided Vehicle market has witnessed significant growth in recent years, driven by the increasing demand for automation and the need for optimized productivity in various industries. AGVs offer several advantages, including improved operational efficiency, reduced labor costs, enhanced safety, and increased throughput. These factors have contributed to the widespread adoption of AGVs across sectors such as manufacturing, warehousing, automotive, healthcare, and e-commerce.

Meaning

Automated Guided Vehicles, commonly known as AGVs, are advanced robotic systems designed to perform material handling tasks autonomously. These vehicles operate in a predefined environment and navigate using various technologies, such as laser-based navigation, magnetic guidance, vision systems, and inertial navigation. AGVs are widely used for tasks such as picking, packing, sorting, transporting goods, and palletizing.

AGVs can be customized according to specific requirements, allowing them to adapt to diverse applications. They can be integrated with existing systems, such as warehouse management software, to optimize workflow and improve overall operational efficiency. AGVs can be categorized into different types, including tow vehicles, forklift AGVs, unit load carriers, and pallet trucks.

Executive Summary

The global Automated Guided Vehicle market is experiencing robust growth due to the increasing demand for automation and the rising need for efficient material handling and logistics solutions. AGVs offer numerous benefits, such as improved productivity, reduced labor costs, enhanced safety, and precise maneuverability. These factors have propelled the adoption of AGVs across various industries, including manufacturing, warehousing, automotive, healthcare, and e-commerce.

The market is witnessing the development of advanced AGV technologies, such as collaborative robots (cobots) and autonomous mobile robots (AMRs), which further enhance the capabilities and flexibility of AGVs. The COVID-19 pandemic has also highlighted the significance of automation in ensuring uninterrupted supply chains, leading to a surge in the adoption of AGVs.

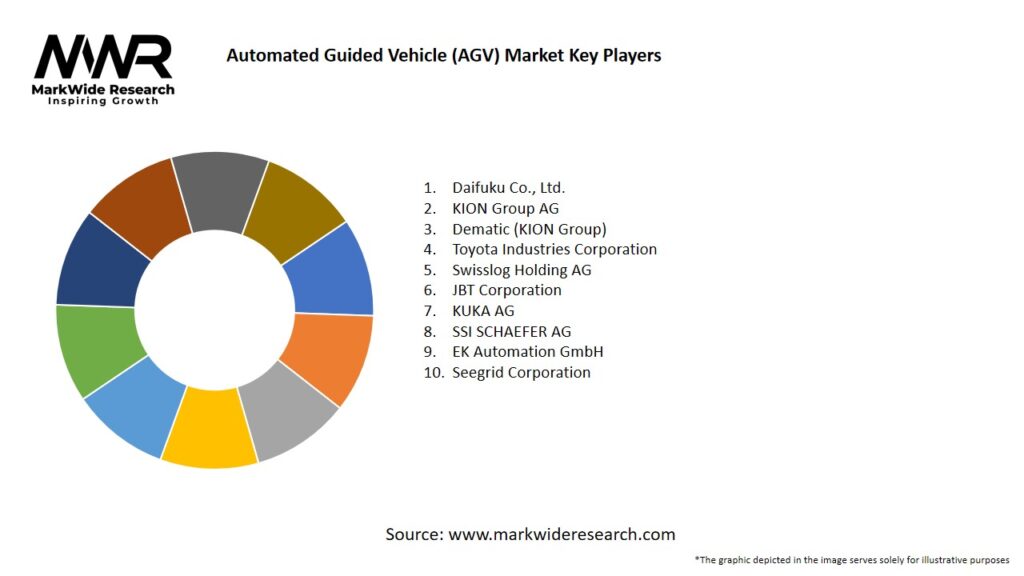

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The Automated Guided Vehicle market is driven by a combination of technological advancements, changing industry requirements, and the need for increased efficiency and productivity. The market dynamics are influenced by factors such as the integration of AI and IoT, expansion in e-commerce, and the focus on workplace safety.

The demand for AGVs is expected to rise steadily, driven by the advantages they offer, including cost reduction, improved safety, and optimization of material flow. However, challenges such as high initial investment costs and the need for workforce adaptation may hinder the market growth to some extent.

AGV manufacturers and solution providers are focusing on research and development activities to enhance the capabilities and functionality of AGVs. Key players in the market are investing in technologies like AI, IoT, and cloud-based systems to offer comprehensive and advanced solutions.

The competitive landscape of the AGV market is characterized by the presence of both established players and new entrants. The market is witnessing collaborations, mergers, and acquisitions, as companies strive to expand their market share and offer integrated solutions to customers.

Regional Analysis

The AGV market exhibits a global presence, with significant growth observed across various regions. North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa are key regions contributing to the market expansion.

Competitive Landscape

Leading Companies in the Automated Guided Vehicle (AGV) Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

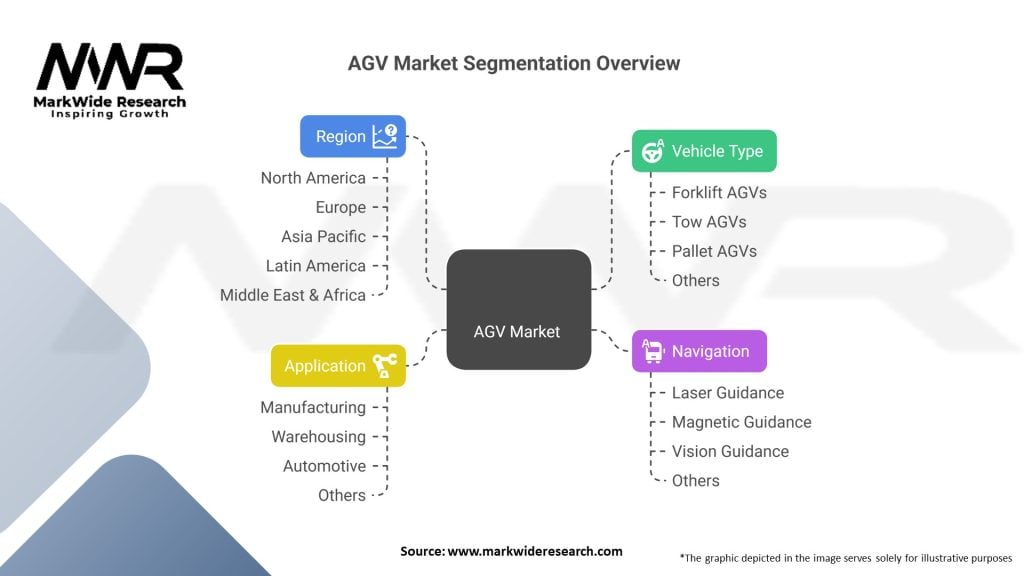

Segmentation

The Automated Guided Vehicle market can be segmented based on various factors, including type, application, industry vertical, and geography.

The segmentation of the market allows for a comprehensive understanding of the AGV landscape, facilitating targeted strategies and solutions for different industry verticals and applications.

Category-wise Insights

Each category of AGVs offers specific functionalities and features, catering to different material handling requirements across industries. The selection of the appropriate AGV type depends on factors such as load capacity, maneuverability, and application-specific needs.

Key Benefits for Industry Participants and Stakeholders

Industry participants and stakeholders, including manufacturers, logistics providers, and e-commerce companies, can harness these benefits to enhance their operational capabilities, drive growth, and stay ahead in a competitive market.

SWOT Analysis

A SWOT (Strengths, Weaknesses, Opportunities, and Threats) analysis provides a comprehensive understanding of the AGV market’s internal and external factors.

Strengths:

Weaknesses:

Opportunities:

Threats:

By understanding the strengths, weaknesses, opportunities, and threats, industry participants can formulate effective strategies to leverage market advantages, overcome challenges, and capitalize on emerging opportunities.

Market Key Trends

These key trends shape the future of the AGV market, driving innovation, enhancing capabilities, and addressing industry-specific requirements.

Covid-19 Impact

The COVID-19 pandemic has had a significant impact on the AGV market, emphasizing the importance of automation and efficient supply chain management. The pandemic-induced disruptions highlighted the vulnerabilities of traditional material handling systems and the need for resilient and agile operations.

AGVs played a crucial role in ensuring uninterrupted supply chains during lockdowns and movement restrictions. The ability of AGVs to operate autonomously and maintain social distancing protocols reduced the reliance on manual labor and minimized the risk of virus transmission.

The e-commerce sector experienced a surge in demand during the pandemic, and AGVs proved instrumental in meeting increased order volumes. AGVs enabled faster order processing, improved inventory management, and enhanced operational efficiency in e-commerce warehouses and distribution centers.

The pandemic also underscored the significance of workplace safety. AGVs eliminated the need for human operators in hazardous and high-risk areas, reducing the exposure of workers to potential health risks.

However, the COVID-19 pandemic also posed challenges to the AGV market. Supply chain disruptions, including disruptions in the production of AGVs and related components, impacted the market growth to some extent. The economic uncertainties and reduced capital expenditure in various industries further affected the adoption of AGVs.

Despite these challenges, the pandemic accelerated the adoption of automation technologies, including AGVs. The lessons learned from the crisis have highlighted the value of AGVs in ensuring business continuity, resilience, and operational efficiency.

Key Industry Developments

These industry developments demonstrate the continuous evolution and innovation within the AGV market, addressing industry demands, and driving market growth.

Analyst Suggestions

By following these suggestions, industry participants can position themselves for sustained growth and success in the competitive AGV market.

Future Outlook

The future of the Automated Guided Vehicle market appears promising, with continued growth expected in the coming years. Factors such as increasing demand for automation, advancements in AI and IoT technologies, and the need for efficient material handling solutions will drive market expansion.

The integration of AGVs with AI, IoT, and cloud-based systems will unlock new possibilities in terms of efficiency, connectivity, and data-driven decision-making. The customization of AGV solutions and the development of industry-specific applications will further fuel market growth.

The adoption of AGVs in emerging economies is expected to rise, driven by industrialization, infrastructure development, and the need for process optimization. The expansion of the e-commerce sector and the focus on sustainable and green technologies will also contribute to market growth.

However, challenges such as high initial investment costs, the need for workforce adaptation, and compliance with safety regulations may pose temporary restraints on market expansion.

Conclusion

The Automated Guided Vehicle (AGV) market is witnessing significant growth and transformation, driven by the increasing demand for automation, the need for efficient material handling solutions, and advancements in technologies such as AI and IoT. AGVs offer numerous benefits, including improved productivity, reduced labor costs, enhanced safety, and streamlined operations. These advantages have led to their widespread adoption across various industries, including manufacturing, warehousing, automotive, healthcare, and e-commerce.

The market is characterized by continuous innovation, with AGV manufacturers focusing on technological advancements, customization, and solution-based offerings. Integration with AI, IoT, and cloud-based systems, as well as collaborations with robotics companies and software providers, are shaping the future of AGVs, enabling enhanced capabilities and comprehensive automation solutions.

In conclusion, the AGV market presents a compelling value proposition for organizations seeking to improve their material handling processes, increase productivity, and achieve operational excellence. By embracing automation, harnessing technological advancements, and leveraging collaborative partnerships, industry participants can position themselves for success in the evolving AGV market and drive the future of efficient and autonomous material handling solutions.

Automated Guided Vehicle (AGV) Market:

| Segmentation | Details |

|---|---|

| Vehicle Type | Forklift AGVs, Tow AGVs, Pallet AGVs, Others |

| Navigation | Laser Guidance, Magnetic Guidance, Vision Guidance, Others |

| Application | Manufacturing, Warehousing, Automotive, Others |

| Region | North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Automated Guided Vehicle (AGV) Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at