Market Overview

The Asia-Pacific Semiconductor Manufacturing Equipment market is a thriving industry that plays a pivotal role in the semiconductor ecosystem. Semiconductor manufacturing equipment refers to the machinery, tools, and systems used in the production and assembly of semiconductors. This market encompasses various types of equipment, including deposition systems, lithography systems, etching equipment, cleaning systems, and wafer inspection systems, among others.

Meaning

Semiconductor manufacturing equipment is crucial for the production of semiconductors, which are the building blocks of modern electronic devices. These equipment ensure the precise fabrication, testing, and packaging of semiconductors, enabling the creation of advanced electronic components used in smartphones, computers, automotive systems, and other electronic devices.

Executive Summary

The Asia-Pacific Semiconductor Manufacturing Equipment market has witnessed significant growth in recent years. The region is home to several leading semiconductor manufacturers and has emerged as a major hub for semiconductor production. The increasing demand for consumer electronics, rapid technological advancements, and the growing adoption of internet of things (IoT) devices are driving the growth of the market in the region.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

- The Asia-Pacific Semiconductor Manufacturing Equipment market is expected to experience substantial growth in the coming years.

- China, Japan, South Korea, and Taiwan are the key countries contributing to the growth of the market in the region.

- The market is driven by the rising demand for advanced electronic devices, such as smartphones and tablets.

- The deployment of 5G technology and the increasing adoption of artificial intelligence (AI) and machine learning (ML) technologies are fueling the demand for semiconductor manufacturing equipment.

- The market is highly competitive, with several established players and new entrants vying for market share.

Market Drivers

The Asia-Pacific Semiconductor Manufacturing Equipment market is propelled by several key drivers:

- Growing Demand for Consumer Electronics: The rising consumer demand for smartphones, tablets, and other electronic devices is driving the need for advanced semiconductors, thereby increasing the demand for semiconductor manufacturing equipment.

- Technological Advancements: The continuous advancements in semiconductor technologies, such as miniaturization, integration, and improved performance, are pushing semiconductor manufacturers to invest in advanced manufacturing equipment to meet the evolving requirements.

- Internet of Things (IoT) Adoption: The proliferation of IoT devices across various industries, including automotive, healthcare, and industrial automation, is boosting the demand for semiconductors and, consequently, semiconductor manufacturing equipment.

- Increasing Deployment of 5G Technology: The rollout of 5G networks requires high-performance semiconductors, driving the demand for advanced manufacturing equipment capable of producing these cutting-edge components.

Market Restraints

Despite the positive growth prospects, the Asia-Pacific Semiconductor Manufacturing Equipment market faces certain challenges:

- High Initial Capital Investment: The establishment of semiconductor manufacturing facilities and the acquisition of advanced equipment involve significant upfront costs, which can act as a barrier for new entrants and smaller players.

- Technological Complexity: Semiconductor manufacturing equipment is highly complex and requires skilled technicians to operate and maintain. The shortage of skilled labor can hinder the market growth to some extent.

- Environmental and Safety Regulations: The semiconductor manufacturing process involves the use of hazardous materials and chemicals. Compliance with stringent environmental and safety regulations can pose challenges for manufacturers and impact market growth.

Market Opportunities

The Asia-Pacific Semiconductor Manufacturing Equipment market offers several lucrative opportunities:

- Expansion of 5G Infrastructure: The ongoing expansion of 5G networks in the Asia-Pacific region presents significant opportunities for semiconductor manufacturing equipment providers. The demand for high-performance semiconductors for 5G infrastructure is expected to surge, driving the need for advanced manufacturing equipment.

- Automotive Sector Growth: The automotive industry is witnessing a rapid transformation with the increasing integration of advanced driver-assistance systems (ADAS), electric vehicles (EVs), and autonomous driving technologies. These advancements require sophisticated semiconductors, creating opportunities for equipment manufacturers.

- Emerging Technologies: The adoption of emerging technologies such as AI, ML, augmented reality (AR), and virtual reality (VR) is on the rise in the Asia-Pacific region. These technologies rely on advanced semiconductors, presenting a growing market for semiconductor manufacturing equipment.

Market Dynamics

The Asia-Pacific Semiconductor Manufacturing Equipment market is characterized by dynamic trends and factors that shape its growth:

- Technological Advancements: Continuous innovations in semiconductor technologies, such as advanced materials, process improvements, and new architectures, drive the need for upgraded manufacturing equipment.

- Industry Collaborations: Semiconductor manufacturers, equipment providers, and research institutions are collaborating to develop cutting-edge technologies and improve the manufacturing processes, fostering market growth.

- Government Initiatives: Governments in the Asia-Pacific region are implementing policies and providing incentives to promote domestic semiconductor manufacturing, which is expected to boost the demand for manufacturing equipment.

- Supply Chain Disruptions: The semiconductor industry is prone to supply chain disruptions, as seen during the COVID-19 pandemic. These disruptions can impact the availability and cost of semiconductor manufacturing equipment.

- Mergers and Acquisitions: The market is witnessing a significant number of mergers and acquisitions as companies aim to strengthen their market position and expand their product portfolios.

Regional Analysis

The Asia-Pacific Semiconductor Manufacturing Equipment market is divided into several key regions, including:

- China: China dominates the regional market due to its extensive semiconductor manufacturing capabilities and investments in technology infrastructure.

- Japan: Japan has a strong presence in the semiconductor industry, driven by its technological expertise and investments in research and development.

- South Korea: South Korea is a key player in the semiconductor manufacturing equipment market, with major companies involved in the production of memory chips and displays.

- Taiwan: Taiwan is renowned for its semiconductor foundries and serves as a major manufacturing hub for global semiconductor companies.

These countries collectively account for a significant share of the Asia-Pacific Semiconductor Manufacturing Equipment market.

Competitive Landscape

Leading Companies in the Asia-Pacific Semiconductor Manufacturing Equipment Market:

- Applied Materials, Inc.

- Tokyo Electron Limited

- ASML Holding N.V.

- Lam Research Corporation

- KLA Corporation

- SCREEN Semiconductor Solutions Co., Ltd.

- Teradyne, Inc.

- Hitachi High-Tech Corporation

- ASM Pacific Technology Ltd.

- Advantest Corporation

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

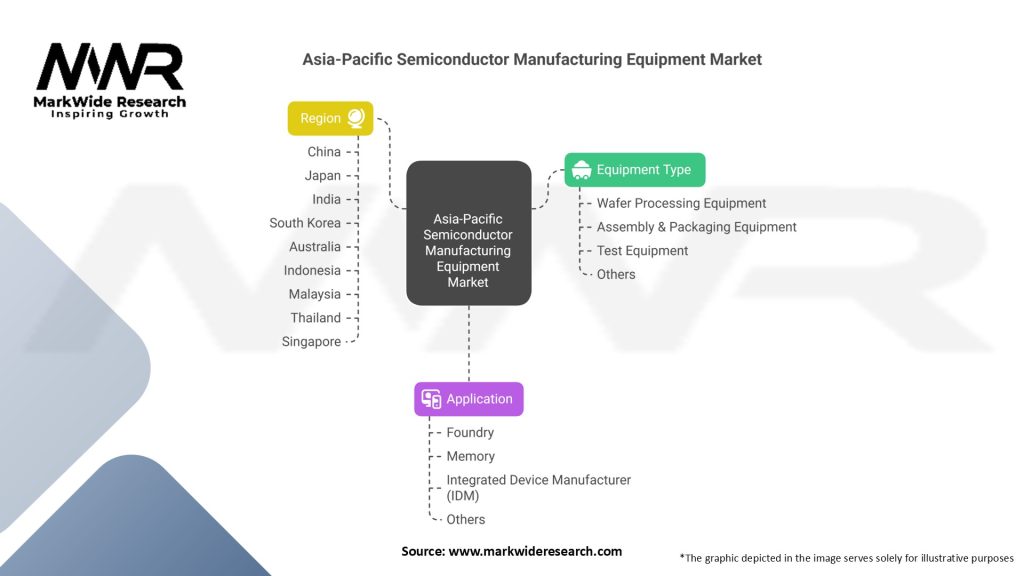

Segmentation

The Asia-Pacific Semiconductor Manufacturing Equipment market can be segmented based on equipment type, end-user industry, and geography:

- By Equipment Type:

- Deposition Systems

- Lithography Systems

- Etching Equipment

- Cleaning Systems

- Wafer Inspection Systems

- Others

- By End-user Industry:

- Electronics

- Automotive

- Industrial

- Healthcare

- Aerospace and Defense

- Others

- By Geography:

- China

- Japan

- South Korea

- Taiwan

- Rest of Asia-Pacific

Category-wise Insights

- Deposition Systems: Deposition systems are used to deposit thin films of various materials onto wafers during the semiconductor fabrication process. They are essential for creating layers with specific properties required for the functioning of semiconductor devices.

- Lithography Systems: Lithography systems play a vital role in the semiconductor manufacturing process by transferring intricate patterns onto wafers. These patterns define the circuitry and components of semiconductor devices.

- Etching equipment: Etching equipment is used to remove specific layers of materials from wafers to create desired patterns and structures. Different types of etching techniques, such as dry etching and wet etching, are employed based on the requirements.

- Cleaning Systems: Cleaning systems are crucial for maintaining the cleanliness and integrity of wafers throughout the manufacturing process. They remove contaminants and particles from the wafer surfaces to ensure optimal performance of the semiconductor devices.

- Wafer Inspection Systems: Wafer inspection systems are employed to detect defects and abnormalities on wafers. These systems use advanced imaging and sensing technologies to identify and categorize defects, enabling manufacturers to ensure the quality of their products.

Key Benefits for Industry Participants and Stakeholders

- Semiconductor Manufacturers: The availability of advanced manufacturing equipment enables semiconductor manufacturers to enhance their production capabilities, improve product quality, and meet the growing demand for semiconductors.

- Equipment Manufacturers: The Asia-Pacific market presents significant opportunities for equipment manufacturers to expand their customer base and increase their revenue through the sale of state-of-the-art semiconductor manufacturing equipment.

- Research and Development Institutions: Collaboration with semiconductor equipment manufacturers offers research institutions access to cutting-edge technologies and facilitates the development of innovative solutions for the semiconductor industry.

- Government Agencies: The growth of the Semiconductor Manufacturing Equipment market positively impacts the economy by attracting investments, generating employment opportunities, and promoting technological advancements in the region.

SWOT Analysis

A SWOT (Strengths, Weaknesses, Opportunities, and Threats) analysis of the Asia-Pacific Semiconductor Manufacturing Equipment market provides insights into its internal and external factors:

- Strengths:

- Strong presence of leading semiconductor manufacturers

- Technological expertise and innovation capabilities

- Favorable government initiatives and policies

- Weaknesses:

- High initial capital investment requirements

- Shortage of skilled labor in some regions

- Environmental and safety regulations

- Opportunities:

- Expansion of 5G infrastructure

- Growing automotive sector

- Adoption of emerging technologies

- Threats:

- Supply chain disruptions

- Intense market competition

- Economic and geopolitical uncertainties

Market Key Trends

- Miniaturization and Integration: The demand for smaller and more integrated semiconductor components is driving the trend of miniaturization and integration, leading to the development of advanced manufacturing equipment capable of achieving higher precision and accuracy.

- Advanced Materials: The utilization of advanced materials, such as gallium nitride (GaN) and silicon carbide (SiC), in semiconductor manufacturing is gaining prominence. Equipment manufacturers are focusing on providing solutions optimized for these materials.

- Smart Manufacturing and Industry 4.0: The integration of smart manufacturing technologies, including automation, data analytics, and connectivity, is revolutionizing the semiconductor manufacturing process. Equipment with intelligent features and connectivity capabilities are becoming increasingly prevalent.

- Sustainable Manufacturing: With the growing emphasis on environmental sustainability, semiconductor manufacturers are adopting eco-friendly practices. Equipment manufacturers are developing solutions that minimize energy consumption, reduce waste, and optimize resource utilization.

Covid-19 Impact

The COVID-19 pandemic had a significant impact on the Asia-Pacific Semiconductor Manufacturing Equipment market. The initial outbreak disrupted global supply chains, causing a shortage of critical components and equipment. However, the semiconductor industry witnessed a strong recovery due to increased demand for electronics, remote working and learning arrangements, and the accelerated digital transformation across industries.

The pandemic highlighted the importance of semiconductor manufacturing and the need for resilient supply chains. It prompted governments to prioritize domestic semiconductor production and invest in semiconductor manufacturing infrastructure. The industry adapted to remote work arrangements, implemented safety protocols, and accelerated digitalization to ensure business continuity.

Key Industry Developments

- Expansion of Semiconductor Foundries: Major semiconductor foundries in the Asia-Pacific region, such as TSMC (Taiwan Semiconductor Manufacturing Company) and Samsung Foundry, have announced plans to expand their manufacturing capacities to meet the growing demand for advanced semiconductors.

- Investments in Advanced Technologies: Several companies are investing in advanced technologies, including extreme ultraviolet (EUV) lithography, to enhance the production capabilities and improve the performance of semiconductor devices.

- Collaboration and Partnerships: Industry players are forming strategic alliances, collaborations, and partnerships to leverage each other’s strengths and accelerate innovation in semiconductor manufacturing equipment.

- Focus on Research and Development: Companies are investing in research and development activities to develop cutting-edge equipment that meets the evolving requirements of semiconductor manufacturers, including higher productivity, improved yields, and cost efficiency.

Analyst Suggestions

Based on the market dynamics and trends, analysts suggest the following strategies for industry participants:

- Focus on Innovation: Continuous innovation in semiconductor manufacturing equipment is crucial to meet the demand for advanced semiconductor components. Companies should invest in research and development to develop technologically advanced and efficient equipment.

- Strengthen Customer Relationships: Building strong relationships with semiconductor manufacturers is essential to understand their evolving needs and provide tailored solutions. Collaborative partnerships and customer-centric approaches can enhance customer satisfaction and loyalty.

- Expand Market Presence: Companies should explore opportunities to expand their market presence by entering new regions, forming strategic alliances, and catering to emerging industries that require semiconductor components.

- Enhance After-Sales Support: Providing comprehensive after-sales support, including maintenance, training, and troubleshooting services, can differentiate equipment manufacturers in the market. Timely support and quick response to customer queries can foster long-term relationships.

Future Outlook

The future outlook for the Asia-Pacific Semiconductor Manufacturing Equipment market is highly promising. The market is expected to witness substantial growth driven by the increasing demand for semiconductors in various industries, advancements in semiconductor technologies, and government initiatives to promote domestic semiconductor manufacturing.

The deployment of 5G networks, the adoption of AI and ML technologies, and the growth of emerging sectors such as electric vehicles, IoT, and automation will continue to drive the demand for advanced semiconductor manufacturing equipment. Companies that adapt to technological advancements, focus on innovation, and provide comprehensive solutions will be well-positioned to capitalize on the market opportunities.

Conclusion

The Asia-Pacific Semiconductor Manufacturing Equipment market is experiencing significant growth due to the rising demand for advanced semiconductors in consumer electronics, the adoption of emerging technologies, and the expansion of 5G infrastructure. Despite challenges such as high initial capital investment and technological complexity, the market offers numerous opportunities for equipment manufacturers, semiconductor manufacturers, and stakeholders.

By embracing technological advancements, fostering innovation, and building strong customer relationships, companies can thrive in this competitive market. The future outlook for the market remains optimistic, with sustained growth expected as the demand for advanced semiconductors continues to rise in the Asia-Pacific region.

Asia-Pacific Semiconductor Manufacturing Equipment Market:

| Segmentation Details |

Information |

| Equipment Type |

Wafer Processing Equipment, Assembly & Packaging Equipment, Test Equipment, Others |

| Application |

Foundry, Memory, Integrated Device Manufacturer (IDM), Others |

| Region |

Asia-Pacific (China, Japan, India, South Korea, Australia, Indonesia, Malaysia, Thailand, Singapore) |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Asia-Pacific Semiconductor Manufacturing Equipment Market:

- Applied Materials, Inc.

- Tokyo Electron Limited

- ASML Holding N.V.

- Lam Research Corporation

- KLA Corporation

- SCREEN Semiconductor Solutions Co., Ltd.

- Teradyne, Inc.

- Hitachi High-Tech Corporation

- ASM Pacific Technology Ltd.

- Advantest Corporation

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

![]()

![]()