Key Industry Developments

- Advancements in Deep Learning: The integration of deep learning algorithms with machine vision systems has led to significant improvements in object recognition, image segmentation, and anomaly detection. This advancement enables more accurate and reliable analysis, enhancing the capabilities of machine vision systems.

- 3D Machine Vision Innovations: The development of 3D machine vision systems has expanded the application possibilities. New technologies such as structured light, time-of-flight, and stereo vision are being utilized to capture and analyze three-dimensional data, enabling tasks such as robotic guidance, volumetric measurements, and 3D inspection.

- Increased Connectivity and Industrial IoT: The integration of machine vision systems with the Industrial Internet of Things (IIoT) and connectivity solutions has enabled real-time monitoring, remote access, and data analytics. This connectivity facilitates predictive maintenance, data-driven decision-making, and seamless integration within smart factory environments.

- Integration with Robotics: Machine vision systems are increasingly being integrated with robotic systems, enabling precise guidance, object recognition, and quality inspection. This integration enhances the capabilities of both technologies, leading to more efficient and accurate automation in manufacturing and logistics operations.

Analyst Suggestions

- Focus on AI Integration: Companies should explore the integration of AI algorithms and deep learning techniques with machine vision systems to enhance their capabilities. This includes leveraging AI for advanced image analysis, pattern recognition, and decision-making, leading to improved accuracy and efficiency.

- Invest in Research and Development: Continuous investment in research and development is crucial to stay ahead in the competitive market. Companies should focus on developing innovative solutions, improving hardware and software components, and exploring new application areas to meet evolving industry needs.

- Address Data Security and Privacy Concerns: Given the increasing reliance on machine vision systems and the collection of sensitive visual data, companies should prioritize data security and address privacy concerns. Implementing robust data protection measures and complying with relevant regulations are essential to gain trust from customers and stakeholders.

- Expand Market Reach in Emerging Economies: Companies should explore opportunities in emerging economies where industrialization and technological advancements are driving the demand for machine vision systems. Expanding market reach through strategic partnerships, localized support, and tailored solutions can unlock significant growth potential.

Future Outlook

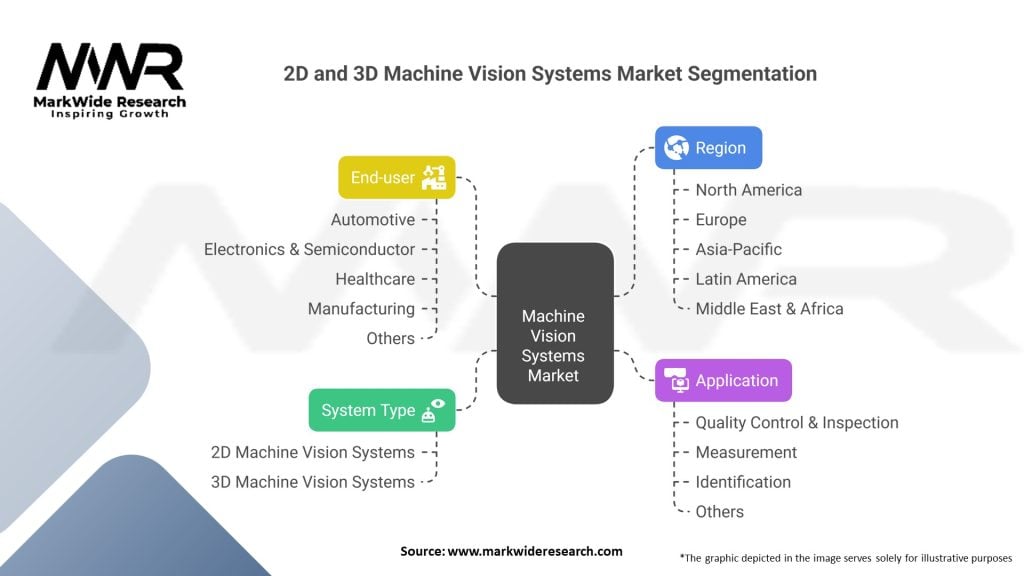

The future of the 2D and 3D Machine Vision Systems Market looks promising, driven by advancements in technology, increasing automation requirements, and the need for accurate quality control. The integration of AI, deep learning, and robotics will further enhance the capabilities of machine vision systems, enabling more sophisticated and efficient applications.

As industries continue to prioritize efficiency, productivity, and quality, the demand for machine vision systems will continue to grow. The expansion of applications into sectors such as healthcare, agriculture, and retail will further fuel market growth. Additionally, the ongoing development of compact and embedded systems will make machine vision technology more accessible to a wider range of industries.

However, companies should remain vigilant about addressing challenges such as high initial costs, skill requirements, and data security concerns. By embracing technological advancements, investing in research and development, and adapting to evolving industry needs, industry participants can seize the opportunities and thrive in the dynamic and competitive 2D and 3D Machine Vision Systems Market.

Conclusion

The 2D and 3D Machine Vision Systems Market offers immense potential for industries seeking to improve quality control, automate processes, and enhance productivity. With the continuous advancements in technology, the integration of AI and deep learning, and the expansion into new application areas, machine vision systems are revolutionizing various industries.

Despite challenges such as high costs and skill requirements, the market is poised for growth, driven by factors such as increasing demand for automation, the emergence of smart factories, and the need for efficient quality control. By embracing technological advancements, investing in research and development, and addressing.