444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview:

The polyethylene terephthalate-glycol (PETG) market is witnessing significant growth due to its wide range of applications across various industries. PETG is a thermoplastic polyester that offers excellent mechanical, chemical, and thermal properties. It is widely used in packaging, automotive, electrical and electronics, and healthcare sectors. This market analysis aims to provide insights into the key trends, drivers, restraints, opportunities, and future outlook of the PETG market.

Meaning:

Polyethylene Terephthalate-Glycol (PETG) is a type of polyester that is formed through the polymerization of ethylene glycol and terephthalic acid. It is known for its transparency, toughness, and versatility. PETG has gained popularity as a substitute for other plastics due to its superior impact resistance, chemical resistance, and ease of processing. It finds extensive applications in the production of bottles, sheets, films, and other packaging materials.

Executive Summary:

The PETG market is experiencing steady growth, driven by the increasing demand for sustainable packaging solutions and the rising awareness of environmental concerns. The market is witnessing a surge in demand from the food and beverage industry, particularly for PETG bottles and containers. The electrical and electronics sector is also adopting PETG for its excellent electrical insulation properties. Additionally, the healthcare industry is utilizing PETG in medical device manufacturing due to its biocompatibility and sterilizability.

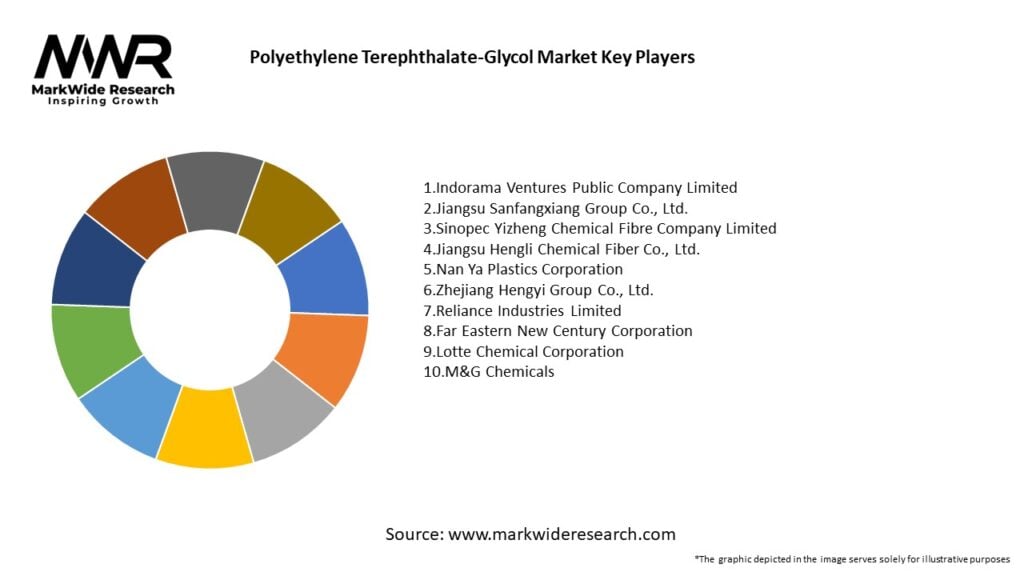

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights:

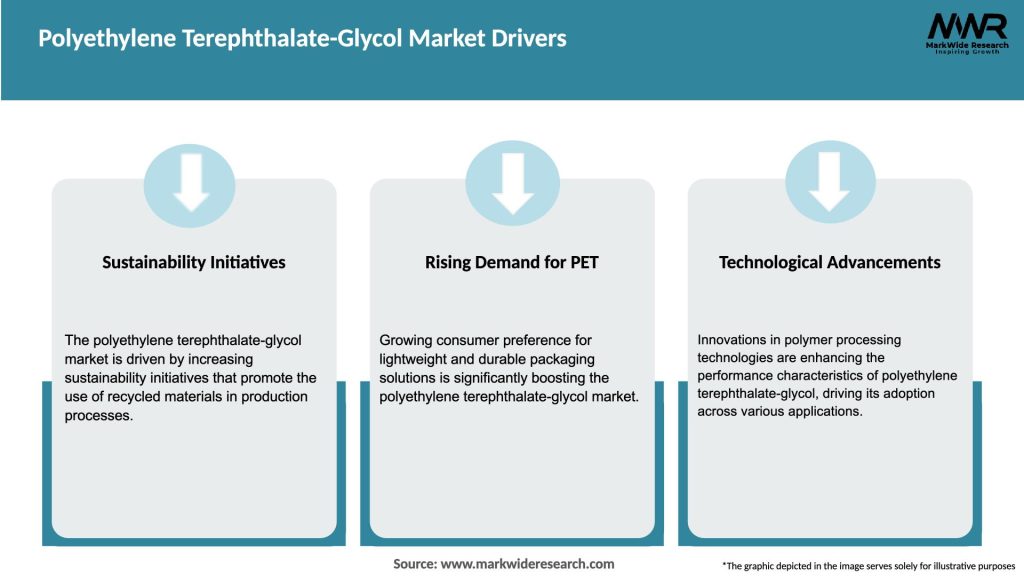

Market Drivers

Growing Demand for Durable Packaging: PETG’s excellent clarity, impact resistance, and chemical inertness make it a preferred choice for food and beverage containers.

Rise of 3D Printing: PETG filament’s balance of strength and ease of printing accelerates adoption in additive manufacturing applications.

Medical and Pharmaceutical Uses: Biocompatibility and sterilization compatibility drive its use in medical devices, vials, and labware.

Regulatory Push for Recyclable Plastics: PETG’s recyclability aligns with sustainability mandates in Europe and North America.

Consumer Preference for Premium Aesthetics: High gloss and transparency support its use in high-end retail displays and cosmetic packaging.

Market Restraints

Higher Cost Than Standard PET: Premium performance comes with a price premium that can deter cost-sensitive applications.

Thermal Limitations: Lower heat deflection temperature compared to some engineering plastics limits high-temperature uses.

Recycling Infrastructure Gaps: Limited dedicated PETG recycling streams can lead to lower recovery rates.

Competition from Alternative Resins: PLA, polycarbonate, and other co-polyesters may offer advantages in specific niches.

Moisture Sensitivity in Storage: Hygroscopic nature requires careful drying and storage to ensure processing quality.

Market Opportunities

Expansion in Medical Packaging: Increasing demand for sterile, clear packaging in biotech and pharmaceutical sectors.

Automotive Interior Components: Potential in decorative trims and transparent housings as OEMs seek lightweight alternatives.

Greenhouse and Horticulture Films: UV-stabilized PETG films for greenhouse glazing and hydroponic applications.

Specialty Sports Equipment: Use in protective gear and helmet visors where clarity and toughness are essential.

Recycled PETG Development: R&D into high-quality recycled PETG to meet circular-economy goals.

Market Dynamics:

The PETG market is driven by a combination of factors including demand from various end-use industries, technological advancements, and regulatory measures. The market dynamics are influenced by the economic growth of regions, consumer preferences, and environmental concerns. The industry players need to stay abreast of market trends, innovate in product development, and adopt sustainable practices to maintain a competitive edge.

Regional Analysis:

The PETG market is segmented into key regions including North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa. Asia Pacific holds a significant share in the market due to the presence of a large consumer base and the expansion of industrial sectors. North America and Europe are witnessing steady growth driven by the demand for sustainable packaging materials and advancements in the healthcare and automotive industries.

Competitive Landscape:

Leading Companies in the Polyethylene Terephthalate-Glycol Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

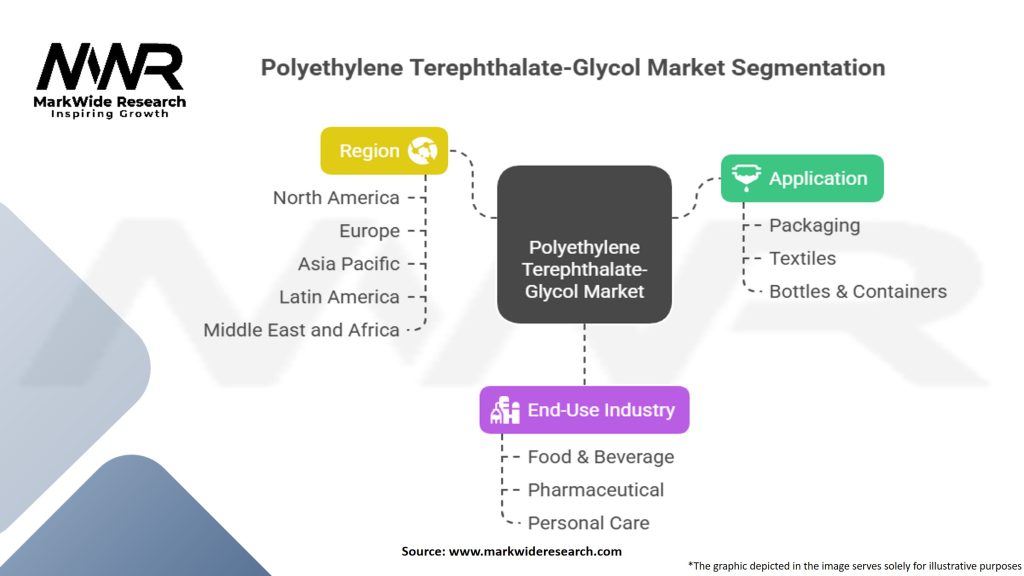

Segmentation:

The PETG market can be segmented based on application, end-use industry, and region. By application, it can be categorized into bottles, sheets, films, and others. Based on end-use industry, it can be divided into packaging, automotive, electrical and electronics, healthcare, and others.

Category-wise Insights:

Key Benefits for Industry Participants and Stakeholders:

SWOT Analysis:

Market Key Trends

Blended and Alloyed Grades: Combination with other polymers for improved temperature and chemical resistance.

Antimicrobial Additives: Incorporation of silver-based or natural antimicrobials for healthcare and food packaging.

Co-Extrusion Multilayer Structures: Enhanced barrier properties through co-extruded PETG layers.

Digital Printing Compatibility: Growing use of direct-to-substrate digital printing on PETG for on-demand customization.

Lightweighting Initiatives: Thinner-wall designs enabled by PETG’s toughness to reduce material use.

Covid-19 Impact:

The COVID-19 pandemic had a mixed impact on the PETG market. While some industries faced disruptions and reduced demand, others experienced increased demand, particularly in the healthcare sector. The market witnessed fluctuations in raw material prices and supply chain disruptions. However, the growing awareness of hygiene and safety measures has increased the demand for PETG packaging solutions.

Key Industry Developments:

Analyst Suggestions:

Future Outlook:

The PETG market is expected to witness steady growth in the coming years. The increasing demand for sustainable packaging solutions, growing awareness of environmental concerns, and advancements in technology are key drivers of market expansion. The development of bio-based variants and the expanding application scope in industries such as automotive and 3D printing present significant growth opportunities. However, market players need to address challenges related to raw material prices and competition from alternative materials.

Conclusion:

The PETG market is experiencing substantial growth driven by its versatile applications in packaging, automotive, electrical and electronics, and healthcare sectors. The demand for sustainable packaging solutions and the superior properties of PETG contribute to its increasing popularity. Market players should focus on innovation, sustainability, and market expansion strategies to capitalize on the growing opportunities in this dynamic industry.

What is Polyethylene Terephthalate-Glycol?

Polyethylene Terephthalate-Glycol, commonly known as PETG, is a thermoplastic polymer that is a variant of polyethylene terephthalate (PET). It is known for its clarity, toughness, and ease of processing, making it suitable for various applications including packaging, medical devices, and consumer products.

What are the key companies in the Polyethylene Terephthalate-Glycol Market?

Key companies in the Polyethylene Terephthalate-Glycol Market include Eastman Chemical Company, BASF SE, and DuPont, among others. These companies are involved in the production and development of PETG for various applications such as packaging and industrial uses.

What are the growth factors driving the Polyethylene Terephthalate-Glycol Market?

The growth of the Polyethylene Terephthalate-Glycol Market is driven by increasing demand for sustainable packaging solutions, the rise in consumer goods requiring durable materials, and advancements in manufacturing technologies that enhance product performance.

What challenges does the Polyethylene Terephthalate-Glycol Market face?

The Polyethylene Terephthalate-Glycol Market faces challenges such as fluctuating raw material prices, environmental concerns regarding plastic waste, and competition from alternative materials like biodegradable plastics.

What opportunities exist in the Polyethylene Terephthalate-Glycol Market?

Opportunities in the Polyethylene Terephthalate-Glycol Market include the development of innovative recycling technologies, increasing applications in the medical and electronics sectors, and the growing trend towards eco-friendly packaging solutions.

What trends are shaping the Polyethylene Terephthalate-Glycol Market?

Trends in the Polyethylene Terephthalate-Glycol Market include a shift towards lightweight and high-performance materials, the integration of smart packaging technologies, and a focus on circular economy practices to enhance sustainability.

Polyethylene Terephthalate-Glycol Market

| Segmentation Details | Details |

|---|---|

| Application | Packaging, Textiles, Bottles & Containers, Others |

| End-Use Industry | Food & Beverage, Pharmaceutical, Personal Care, Others |

| Region | North America, Europe, Asia Pacific, Latin America, Middle East and Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Polyethylene Terephthalate-Glycol Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at