Market Overview

Industrial pumping machinery plays a critical role in various sectors, including manufacturing, oil and gas, water and wastewater treatment, and chemical processing. These machines are designed to move fluids from one location to another, enabling the smooth operation of industrial processes. The global industrial pumping machinery market has witnessed significant growth in recent years, driven by the increasing demand for efficient and reliable pumping solutions across multiple industries.

Meaning

Industrial pumping machinery refers to a range of equipment used to transport fluids in industrial settings. These machines are designed to handle different types of fluids, including liquids, gases, and slurries. They come in various forms, such as centrifugal pumps, positive displacement pumps, and reciprocating pumps, each suited for specific applications. The primary function of industrial pumping machinery is to generate enough force to move fluids through pipelines, ensuring a continuous flow within industrial processes.

Executive Summary

The industrial pumping machinery market is experiencing steady growth worldwide due to the rising need for efficient fluid transportation systems in industrial operations. Manufacturers are focusing on developing advanced pumping technologies to enhance productivity, minimize energy consumption, and reduce maintenance costs. The market is highly competitive, with key players striving to gain a competitive edge by offering innovative solutions and expanding their product portfolios. Regional analysis reveals that Asia Pacific holds a significant share in the global market, driven by rapid industrialization and infrastructure development in countries like China and India.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

- Growing demand for energy-efficient pumping solutions drives market growth.

- Increasing focus on sustainable and eco-friendly pumping technologies.

- Technological advancements, such as the integration of IoT and automation, are shaping the market.

- Water and wastewater treatment industry presents lucrative opportunities for market players.

- Stringent government regulations regarding environmental protection impact market dynamics.

Market Drivers

The industrial pumping machinery market is fueled by several key drivers that contribute to its growth and expansion. These drivers include:

- Growing Industrialization: Rapid industrialization across the globe has led to increased demand for industrial pumping machinery. Industries such as manufacturing, oil and gas, and chemical processing require efficient pumping systems to support their operations.

- Infrastructure Development: Infrastructure development projects, particularly in emerging economies, require reliable pumping machinery for various applications, including water supply, sewage systems, and construction activities.

- Demand for Energy-efficient Solutions: Rising energy costs and environmental concerns have prompted industries to seek energy-efficient pumping solutions. Manufacturers are focusing on developing pumps with advanced features to optimize energy consumption.

- Increasing Focus on Water and Wastewater Treatment: The need for clean water and effective wastewater treatment has driven the demand for industrial pumping machinery in the water and wastewater treatment industry. Pumping systems play a crucial role in the efficient movement of water and sewage through treatment plants.

- Technological Advancements: The integration of advanced technologies, such as IoT, automation, and remote monitoring, has revolutionized the industrial pumping machinery market. These technologies improve pump performance, enable real-time monitoring, and facilitate predictive maintenance.

Market Restraints

While the industrial pumping machinery market presents significant growth opportunities, certain factors restrain its progress:

- High Initial Investment: The installation and maintenance of industrial pumping systems require substantial capital investment. This can pose a challenge, especially for small and medium-sized enterprises (SMEs), limiting their adoption of advanced pumping technologies.

- Operational Challenges: Industrial pumps can encounter operational challenges, such as cavitation, corrosion, and mechanical failures, which can impact their efficiency and lifespan. Regular maintenance and skilled workforce are necessary to address these challenges.

- Environmental Concerns: Stringent government regulations regarding emissions, energy consumption, and waste disposal impose compliance challenges for pump manufacturers. Adhering to these regulations adds complexity and cost to the production and operation of pumping systems.

- Volatility in Raw Material Prices: Fluctuations in raw material prices, particularly metals such as steel and iron, can affect the cost of manufacturing pumping machinery. This volatility can impact the profitability of pump manufacturers and hinder market growth.

Market Opportunities

The industrial pumping machinery market offers several opportunities for growth and expansion:

- Emerging Economies: Developing economies, especially in Asia Pacific and Latin America, present significant growth opportunities for industrial pumping machinery. Rapid industrialization, urbanization, and infrastructure development activities in these regions drive the demand for pumping systems.

- Renewable Energy Sector: The growing focus on renewable energy sources, such as wind and solar power, creates opportunities for pumping machinery. Pumps are required for cooling, lubrication, and fluid transfer in renewable energy installations.

- Water and Wastewater Treatment: The increasing need for clean water and efficient wastewater treatment systems offers promising prospects for the industrial pumping machinery market. Advanced pumping solutions are essential for the effective movement and treatment of water and sewage in treatment plants.

- Technological Advancements: Continuous advancements in pump technologies, including the integration of IoT, automation, and predictive maintenance, present opportunities for pump manufacturers to offer innovative and efficient solutions.

- Retrofitting and Upgradation: Many industries are retrofitting their existing pumping systems with more advanced and energy-efficient solutions. Retrofitting offers a cost-effective alternative to complete system replacement and enables industries to enhance the performance and efficiency of their operations.

Market Dynamics

The industrial pumping machinery market is influenced by various dynamic factors that shape its growth trajectory:

- Technological Advancements: The integration of advanced technologies, such as IoT, automation, and data analytics, has transformed the industrial pumping machinery market. These technologies enable real-time monitoring, predictive maintenance, and remote control, enhancing the efficiency and reliability of pumping systems.

- Competitive Landscape: The market is highly competitive, with numerous global and regional players vying for market share. Key players focus on offering innovative and energy-efficient solutions to gain a competitive edge. Mergers and acquisitions, partnerships, and collaborations are common strategies adopted by companies to expand their product portfolios and geographical reach.

- Regulatory Landscape: Governments worldwide are implementing stringent regulations to address environmental concerns and promote sustainable industrial practices. Pump manufacturers need to comply with these regulations, such as energy efficiency standards and emission limits, which influence the design and manufacturing of pumping systems.

- Economic Factors: Economic conditions, such as GDP growth, inflation rates, and industrial output, impact the industrial pumping machinery market. Economic downturns can lead to reduced investments in industrial sectors, affecting the demand for pumping machinery.

- Environmental Concerns: Increasing awareness of environmental issues drives the demand for eco-friendly pumping solutions. Pump manufacturers are focusing on developing energy-efficient pumps with reduced carbon footprints and environmentally friendly materials.

Regional Analysis

The industrial pumping machinery market exhibits regional variations in terms of market size, growth rate, and key players. The major regions analyzed in this report include:

- North America: The North American market is driven by industries such as oil and gas, manufacturing, and water and wastewater treatment. The United States and Canada are the major contributors to the regional market, with a strong focus on technological advancements and energy efficiency.

- Europe: Europe is a mature market for industrial pumping machinery, with well-established industries and stringent environmental regulations. Germany, France, and the United Kingdom are the key countries driving market growth in this region.

- Asia Pacific: The Asia Pacific region dominates the global industrial pumping machinery market, driven by rapid industrialization and infrastructure development in countries like China, India, and Southeast Asian nations. The manufacturing sector and water and wastewater treatment industry offer substantial growth opportunities in this region.

- Latin America: Latin America presents significant growth potential due to increasing investments in industries such as oil and gas, mining, and water infrastructure. Brazil, Mexico, and Argentina are the key markets in this region.

- Middle East and Africa: The Middle East and Africa region witness growth in the industrial pumping machinery market due to oil and gas exploration and production activities. Countries like Saudi Arabia, the United Arab Emirates, and South Africa contribute to market growth in this region.

Competitive Landscape

Leading Companies in the Industrial Pumping Machinery Market:

- Grundfos Holding A/S

- Xylem Inc.

- KSB SE & Co. KGaA

- Flowserve Corporation

- Sulzer Ltd

- Ebara Corporation

- ITT Inc.

- Wilo SE

- SPX FLOW, Inc.

- Pentair plc

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

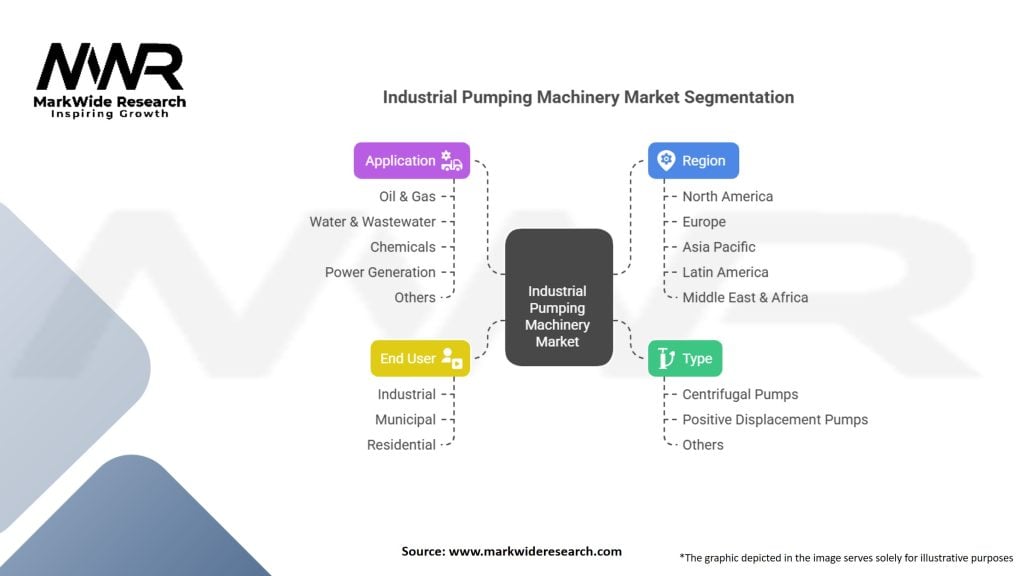

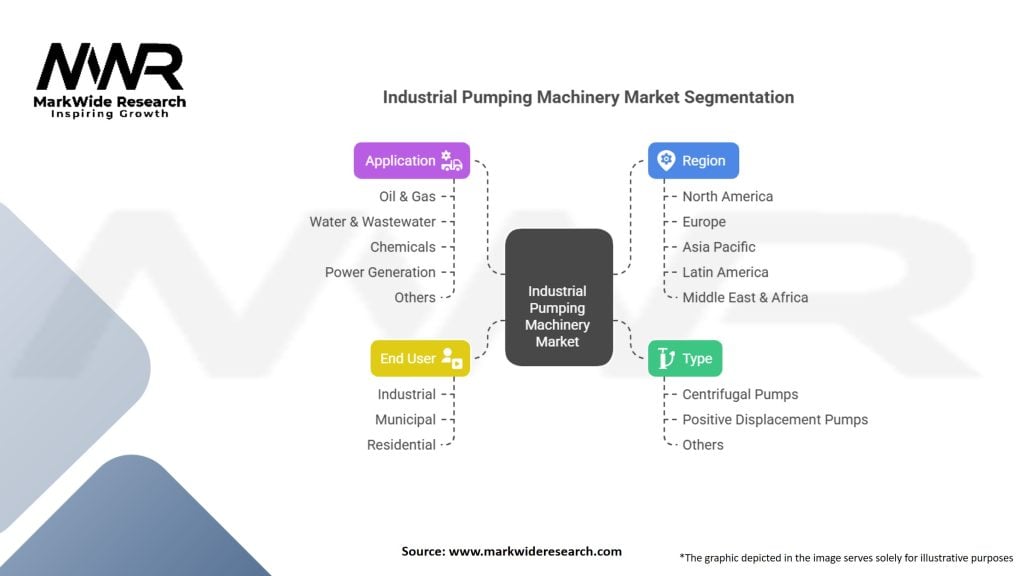

Segmentation

The industrial pumping machinery market can be segmented based on various factors, including pump type, end-use industry, and region. The following segmentation provides a comprehensive analysis of the market:

- By Pump Type:

- Centrifugal Pumps

- Positive Displacement Pumps

- Reciprocating Pumps

- Others

- By End-use Industry:

- Oil and Gas

- Manufacturing

- Water and Wastewater Treatment

- Chemical Processing

- Power Generation

- Others

- By Region:

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East and Africa

Category-wise Insights

- Centrifugal Pumps:

- Centrifugal pumps dominate the industrial pumping machinery market, accounting for the largest share. They are widely used in various industries due to their high efficiency, low maintenance requirements, and versatility.

- Positive Displacement Pumps:

- Positive displacement pumps are preferred for applications that require high pressure and precise flow control. They find extensive use in industries such as oil and gas, chemical processing, and pharmaceuticals.

- Reciprocating Pumps:

- Reciprocating pumps are known for their high-pressure capabilities and are commonly used in industries requiring high-pressure pumping, such as oil and gas exploration and water jetting.

- Oil and Gas Industry:

- The oil and gas industry is a significant end-user of industrial pumping machinery. Pumps are utilized for various applications, including crude oil transportation, refinery processes, and offshore drilling operations.

- Manufacturing Industry:

- The manufacturing industry relies on pumping machinery for processes such as material handling, coolant circulation, and hydraulic systems. The demand for efficient and reliable pumps in manufacturing plants drives market growth.

- Water and Wastewater Treatment:

- Water and wastewater treatment is a critical application for industrial pumping machinery. Pumps play a vital role in water supply, sewage systems, and treatment plant processes, ensuring the efficient movement of fluids.

- Power Generation:

- The power generation industry requires pumps for cooling systems, boiler feedwater circulation, and condensate extraction. As the demand for electricity continues to rise, the need for pumping machinery in power plants increases.

Key Benefits for Industry Participants and Stakeholders

The industrial pumping machinery market offers several benefits for industry participants and stakeholders:

- Increased Efficiency: Industrial pumping machinery improves operational efficiency by ensuring a continuous flow of fluids within industrial processes. Efficient pumps minimize downtime, reduce energy consumption, and enhance overall productivity.

- Cost Savings: Advanced pumping technologies enable cost savings through improved energy efficiency and reduced maintenance requirements. Energy-efficient pumps help industries save on energy costs, while predictive maintenance strategies minimize unexpected breakdowns and costly repairs.

- Enhanced Reliability: Reliable pumping systems are crucial for industries to maintain smooth operations. Industrial pumping machinery provides reliable fluid transportation, reducing the risk of process disruptions and equipment failures.

- Environmental Compliance: With increasing environmental regulations, industrial pumping machinery helps industries comply with emission standards and reduce their carbon footprints. Energy-efficient pumps contribute to sustainable operations and environmental protection.

- Technological Advancements: The integration of advanced technologies in industrial pumping machinery opens up opportunities for industries to optimize their processes. IoT-enabled pumps, automation, and remote monitoring enhance operational control and enable predictive maintenance.

SWOT Analysis

A SWOT (Strengths, Weaknesses, Opportunities, Threats) analysis of the industrial pumping machinery market provides valuable insights into its internal and external factors:

- Strengths:

- Technological advancements and innovation drive market growth.

- Diverse product portfolios cater to various industry needs.

- Strong distribution networks ensure global market presence.

- Established customer base and brand reputation.

- Weaknesses:

- High initial investment and installation costs limit market penetration.

- Operational challenges, such as cavitation and mechanical failures, impact reliability.

- Complex regulatory compliance requirements add complexity to manufacturing processes.

- Opportunities:

- Emerging economies offer growth potential with rapid industrialization.

- Demand for energy-efficient pumping solutions drives market expansion.

- Water and wastewater treatment industry presents significant opportunities.

- Technological advancements, such as IoT integration, offer innovative possibilities.

- Threats:

- Intense market competition leads to price pressure and reduced profit margins.

- Economic downturns can impact industrial investments and market growth.

- Fluctuating raw material prices affect manufacturing costs.

- Stringent environmental regulations impose compliance challenges.

Market Key Trends

The industrial pumping machinery market is influenced by several key trends:

- Energy Efficiency: The focus on energy-efficient pumping solutions continues to grow, driven by rising energy costs and environmental concerns. Manufacturers are developing pumps with improved efficiency and integrating advanced control systems to optimize energy consumption.

- IoT Integration: The integration of IoT technology enables real-time monitoring, remote control, and predictive maintenance of pumping systems. IoT-enabled pumps provide valuable data insights, leading to improved operational efficiency and reduced downtime.

- Automation and Robotics: Automation and robotics are revolutionizing the industrial pumping machinery market. Automated systems offer enhanced precision, reliability, and speed, optimizing pumping processes and reducing the reliance on manual intervention.

- Sustainability and Eco-Friendly Solutions: The industry is witnessing a shift towards sustainable and eco-friendly pumping solutions. Pump manufacturers are developing pumps with reduced carbon footprints, utilizing eco-friendly materials, and focusing on recycling and waste reduction.

- Remote Monitoring and Predictive Maintenance: Remote monitoring systems enable real-time data analysis and proactive maintenance of pumping machinery. Predictive maintenance strategies minimize unplanned downtime and reduce maintenance costs, enhancing overall system reliability.

Covid-19 Impact

The COVID-19 pandemic had a mixed impact on the industrial pumping machinery market:

- Disruptions in Supply Chains: The pandemic led to disruptions in global supply chains, affecting the production and delivery of industrial pumping machinery. Restrictions on movement and temporary shutdowns of manufacturing facilities resulted in delays and supply shortages.

- Reduced Industrial Activities: Lockdown measures and reduced industrial activities during the pandemic resulted in decreased demand for industrial pumping machinery. Industries such as manufacturing, oil and gas, and construction witnessed temporary slowdowns, affecting the market.

- Focus on Essential Services: The water and wastewater treatment industry, classified as an essential service, continued to operate during the pandemic. This sector sustained the demand for pumping machinery, particularly for sewage treatment and water supply systems.

- Shift towards Remote Monitoring and Automation: The pandemic accelerated the adoption of remote monitoring and automation technologies in the pumping industry. Industries sought ways to minimize human intervention and enable remote operations, leading to increased investments in IoT-enabled pumping systems.

- Recovery and Resilience: As economies recover from the pandemic, industries are gradually resuming operations and investing in infrastructure projects. The demand for industrial pumping machinery is expected to rebound as industrial activities regain momentum.

Key Industry Developments

The industrial pumping machinery market has witnessed significant industry developments in recent years:

- Technological Advancements: Pump manufacturers are investing in research and development to introduce technologically advanced pumping solutions. These include the integration of IoT, automation, and predictive maintenance capabilities, improving pump performance and reliability.

- Strategic Collaborations and Partnerships: Key players in the market are forming strategic collaborations and partnerships to expand their product portfolios and geographic presence. Collaborations enable companies to leverage complementary expertise and cater to a wider customer base.

- Mergers and Acquisitions: Mergers and acquisitions have been prevalent in the industrial pumping machinery market, leading to consolidation and market expansion. Large companies acquire smaller firms to enhance their capabilities, gain access to new markets, and strengthen their competitive position.

- Focus on Energy Efficiency: Pump manufacturers are increasingly focusing on developing energy-efficient pumping solutions. This includes the use of advanced motor technologies, optimized hydraulic designs, and smart control systems to minimize energy consumption and operational costs.

- Sustainable Manufacturing Practices: The industry is embracing sustainable manufacturing practices by reducing carbon emissions, optimizing resource utilization, and adopting eco-friendly materials. Pump manufacturers are incorporating circular economy principles, recycling, and waste reduction strategies into their operations.

Analyst Suggestions

Based on market analysis and trends, analysts provide the following suggestions for industry participants:

- Embrace Technological Advancements: Stay updated with the latest technological advancements in industrial pumping machinery. Focus on incorporating IoT, automation, and predictive maintenance capabilities into product offerings to enhance efficiency and customer satisfaction.

- Develop Energy-efficient Solutions: Invest in research and development to develop energy-efficient pumping solutions. Energy efficiency is a key factor influencing purchasing decisions, and companies that offer energy-saving pumps have a competitive advantage.

- Strengthen Distribution Networks: Expand distribution networks to reach a wider customer base and enhance market presence. Collaborate with distributors and agents in different regions to improve market penetration and customer reach.

- Focus on After-sales Services: Provide comprehensive after-sales services, including maintenance, repairs, and spare parts availability. Strong after-sales support builds customer loyalty and satisfaction, contributing to long-term business relationships.

- Collaborate for Innovation: Foster collaborations and partnerships with technology providers, research institutes, and industry experts to drive innovation. Collaborative efforts can lead to the development of cutting-edge pumping technologies and solutions.

Future Outlook

The future of the industrial pumping machinery market looks promising, driven by technological advancements, increasing demand for energy-efficient solutions, and infrastructure development projects. Key trends, such as IoT integration, automation, and sustainability, will continue to shape the market. As industries prioritize efficiency, reliability, and environmental sustainability, the demand for advanced pumping technologies will rise. Market players that focus on innovation, customer-centric solutions, and strategic partnerships are likely to thrive in this dynamic market.

Conclusion

The industrial pumping machinery market is witnessing steady growth due to the rising demand for efficient and reliable pumping solutions in various industries. Technological advancements, such as IoT integration and automation, are transforming the market, enabling improved performance and predictive maintenance. The market presents opportunities in emerging economies, renewable energy sectors, and water and wastewater treatment applications. However, challenges such as high initial investment, operational complexities, and regulatory compliance need to be addressed. By embracing innovation, energy efficiency, and sustainable practices, industry participants can position themselves for success in this competitive market.

Industrial Pumping Machinery Market

| Segmentation |

Details |

| Type |

Centrifugal Pumps, Positive Displacement Pumps, Others |

| Application |

Oil & Gas, Water & Wastewater, Chemicals, Power Generation, Others |

| End User |

Industrial, Municipal, Residential |

| Region |

North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Industrial Pumping Machinery Market:

- Grundfos Holding A/S

- Xylem Inc.

- KSB SE & Co. KGaA

- Flowserve Corporation

- Sulzer Ltd

- Ebara Corporation

- ITT Inc.

- Wilo SE

- SPX FLOW, Inc.

- Pentair plc

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA