444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The global electric gripper market is experiencing significant growth due to the increasing adoption of automation in various industries. Electric grippers are advanced robotic devices used to grasp and manipulate objects with precision. They are widely employed in industries such as automotive, electronics, pharmaceuticals, food and beverage, and logistics, among others. The demand for electric grippers is driven by their ability to improve operational efficiency, enhance productivity, and reduce labor costs.

Meaning

Electric grippers are robotic tools designed to grasp and handle objects with precision and accuracy. They are equipped with electric motors and sensors that enable them to perform delicate tasks with varying degrees of force. Electric grippers are used in various industries to automate gripping and manipulation processes, replacing manual labor and improving overall operational efficiency.

Executive Summary

The global electric gripper market is witnessing steady growth, driven by the rising demand for automation across industries. The market is characterized by the presence of several key players offering a wide range of electric gripper solutions. Key market trends include the integration of advanced sensing technologies, the development of lightweight and compact grippers, and the adoption of collaborative robots. The market is expected to witness further growth in the coming years, fueled by technological advancements and the increasing need for efficient handling and manipulation of objects.

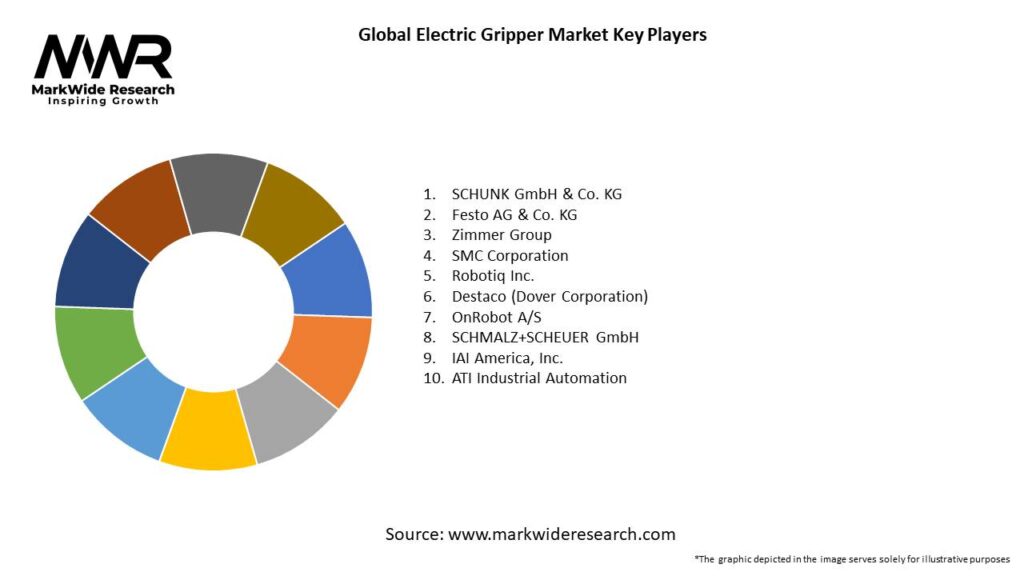

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

The Electric Gripper market is projected to grow at a CAGR of ~9% through 2030, driven by increased robotization in manufacturing and logistics.

Two-finger parallel and adaptive multi-finger grippers together comprise ~70% of unit shipments.

Asia-Pacific leads in volume due to large automotive and electronics contract manufacturing sectors; Europe commands high-value custom gripper sales.

Growing demand for clean-room and sterile-compatible grippers in pharmaceutical and food industries is fueling specialty segments.

Integration of force-torque sensing and vision-guided capabilities is becoming a standard feature in advanced gripper models.

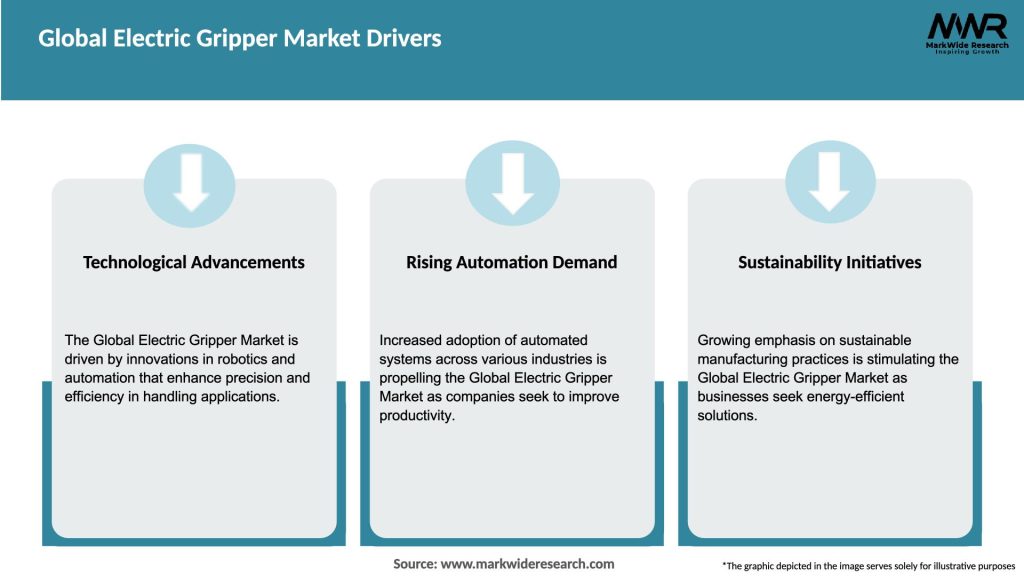

Market Drivers

Automation Intensification: Manufacturers adopt flexible automation to address labor shortages and increase throughput.

SME Adoption: Plug-and-play electric grippers lower entry barriers for small and mid-sized enterprises.

Versatility Needs: Electric grippers offer adjustable gripping force and configuration for mixed-product lines.

Energy Efficiency: Lower power consumption compared to pneumatic grippers aligns with sustainability goals.

Industry 4.0 Integration: Connectivity and smart diagnostics enable predictive maintenance and minimal downtime.

Market Restraints

Higher Initial Cost: Electric grippers are generally more expensive than pneumatic counterparts, affecting ROI calculations.

Payload Limitations: Some electric models have lower maximum force compared to hydraulic or pneumatic solutions.

Complexity of Control: Programming multi-axis motion and force parameters requires advanced robotics expertise.

Standardization Gaps: Lack of universal mounting and communication protocols can complicate system integration.

Service & Support: Dependence on OEM for firmware updates and repairs can lead to longer lead times.

Market Opportunities

Collaborative Robotics: Lightweight electric grippers optimized for safe human–robot collaboration in assembly tasks.

End-Taster Integration: Combining grippers with tactile sensors for robotized quality inspection and adaptive picking.

Modular End-Effector Kits: Quick-change gripper interfaces allowing rapid tool swapping on multi-cell robots.

Soft Gripper Technologies: Development of compliant, silicone-based fingers for delicate object handling in food and pharma.

Cloud-Based Analytics: Remote performance monitoring and usage analytics to optimize gripper selection and lifecycle management.

Market Dynamics

The global electric gripper market is dynamic, driven by technological advancements, changing industry needs, and evolving market trends. The market is highly competitive, with key players investing in research and development to develop innovative and efficient gripper solutions. Collaborative robots, or cobots, are gaining popularity, enabling human-robot collaboration and enhancing operational flexibility. Additionally, the market is witnessing increased adoption of electric grippers in small and medium-sized enterprises, as well as the integration of artificial intelligence and machine learning capabilities to enhance gripping performance.

Regional Analysis

The electric gripper market is segmented into several regions, including North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa. North America holds a significant share of the market due to the presence of established industries and high adoption of automation. Europe follows closely, driven by stringent industrial regulations and the need for efficient manufacturing processes. The Asia Pacific region is witnessing rapid growth, attributed to the expanding manufacturing sector, increasing industrial automation, and rising investments in robotics and automation technologies.

Competitive Landscape

Leading companies in the Global Electric Gripper Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

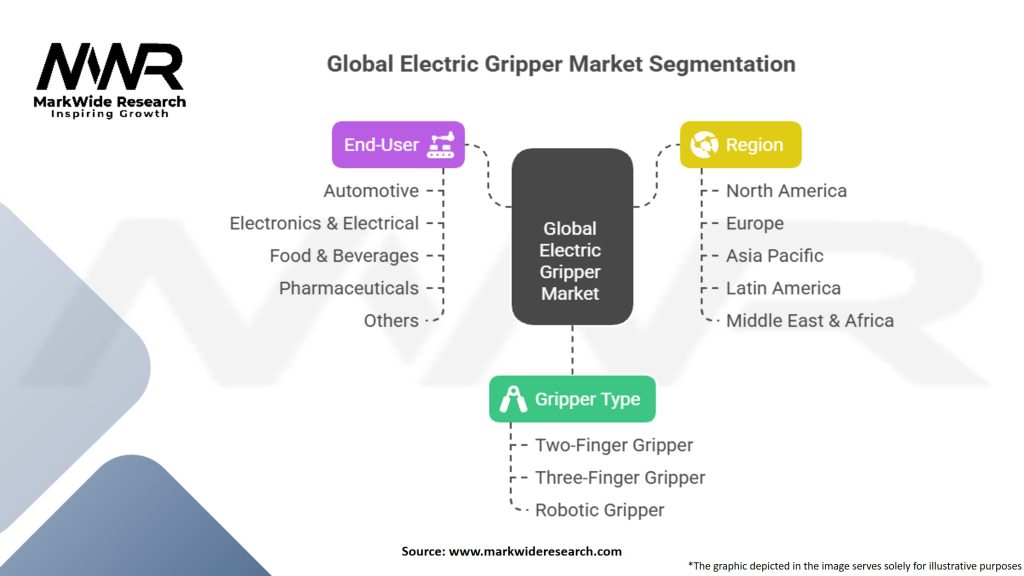

Segmentation

The electric gripper market can be segmented based on grip type, application, end-use industry, and geography. By grip type, the market can be divided into two-finger grippers, three-finger grippers, and multi-finger grippers. By application, the market includes handling and assembly, packaging and palletizing, machine tending, electronics, automotive, and others. By end-use industry, the market covers automotive, electronics, pharmaceuticals, food and beverage, logistics, and others.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Market Key Trends

Covid-19 Impact

The COVID-19 pandemic had both positive and negative impacts on the electric gripper market. On one hand, the pandemic accelerated the adoption of automation and robotics in industries to ensure business continuity and reduce human contact. This drove the demand for electric grippers, especially in industries such as e-commerce, healthcare, and logistics. On the other hand, supply chain disruptions and economic uncertainties slowed down investments in automation and robotics, affecting the market growth to some extent.

Key Industry Developments

Analyst Suggestions

Future Outlook

The global electric gripper market is poised for significant growth in the coming years. Technological advancements, increasing adoption of automation, and the need for efficient handling and manipulation of objects are key drivers for market expansion. Integration of artificial intelligence and machine learning capabilities, customization for specific applications, and expansion in emerging markets are expected to present lucrative opportunities. With ongoing advancements in gripper technologies and the evolving needs of industries, the electric gripper market is set to witness continuous innovation and development.

Conclusion

The global electric gripper market is experiencing robust growth due to the increasing demand for automation and efficient handling of objects in various industries. Electric grippers offer precise gripping capabilities, enhance operational efficiency, and reduce labor costs. The market is driven by advancements in sensing technologies, the development of lightweight and compact grippers, and the adoption of collaborative robots.

Despite challenges such as initial investment costs and integration complexities, the market presents opportunities for expansion, customization, and integration with advanced technologies. With continuous innovation and increasing adoption across industries, the electric gripper market is set to witness a promising future.

What is Electric Gripper?

Electric grippers are devices used in automation and robotics to grasp and manipulate objects. They utilize electric actuators to provide precise control and are commonly used in manufacturing, assembly, and packaging applications.

What are the key players in the Global Electric Gripper Market?

Key players in the Global Electric Gripper Market include companies like Schunk, Zimmer Group, and Applied Robotics, which are known for their innovative solutions in automation and robotics, among others.

What are the main drivers of growth in the Global Electric Gripper Market?

The growth of the Global Electric Gripper Market is driven by the increasing demand for automation in various industries, advancements in robotics technology, and the need for precision in manufacturing processes.

What challenges does the Global Electric Gripper Market face?

Challenges in the Global Electric Gripper Market include high initial costs of electric grippers, the complexity of integration with existing systems, and the need for skilled personnel to operate advanced robotic systems.

What opportunities exist in the Global Electric Gripper Market?

Opportunities in the Global Electric Gripper Market include the expansion of automation in emerging markets, the development of smart grippers with enhanced capabilities, and the increasing adoption of electric grippers in the logistics and warehousing sectors.

What trends are shaping the Global Electric Gripper Market?

Trends in the Global Electric Gripper Market include the rise of collaborative robots, advancements in sensor technology for better object detection, and the growing focus on sustainability in manufacturing processes.

Global Electric Gripper Market

| Segmentation Details | Information |

|---|---|

| Gripper Type | Two-Finger Gripper, Three-Finger Gripper, Robotic Gripper |

| End-User | Automotive, Electronics & Electrical, Food & Beverages, Pharmaceuticals, Others |

| Region | North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the Global Electric Gripper Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at