444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

The Indonesia cloth market represents one of Southeast Asia’s most dynamic and rapidly evolving textile sectors, characterized by robust domestic demand and expanding export capabilities. Indonesia’s textile industry has emerged as a cornerstone of the nation’s manufacturing economy, driven by favorable demographics, increasing urbanization, and growing consumer purchasing power. The market encompasses a diverse range of products including cotton fabrics, synthetic textiles, traditional batik cloth, and modern fashion materials.

Market dynamics indicate sustained growth momentum, with the sector experiencing a compound annual growth rate of 6.2% over recent years. This expansion reflects Indonesia’s strategic position as both a major textile producer and consumer market in the Asia-Pacific region. The domestic market benefits from a population exceeding 270 million people, creating substantial demand for clothing and textile products across various price segments and quality categories.

Manufacturing capabilities have strengthened significantly, with Indonesian textile producers investing heavily in modern equipment and sustainable production technologies. The country’s competitive advantages include abundant raw material resources, skilled workforce, and strategic geographic location facilitating access to major export markets. Export performance has shown consistent improvement, with Indonesian cloth products gaining recognition in international markets for quality and competitive pricing.

The Indonesia cloth market refers to the comprehensive ecosystem encompassing the production, distribution, and consumption of textile fabrics within Indonesia’s domestic economy and export channels. This market includes various fabric types ranging from traditional handwoven textiles to modern synthetic materials, serving both local consumer needs and international trade requirements.

Market scope extends beyond basic fabric production to include value-added processes such as dyeing, printing, finishing, and garment manufacturing. The sector represents a critical component of Indonesia’s industrial base, contributing significantly to employment generation, foreign exchange earnings, and regional economic development. Traditional elements such as batik and ikat weaving coexist with modern textile manufacturing, creating a unique market characterized by cultural heritage and contemporary innovation.

Indonesia’s cloth market demonstrates remarkable resilience and growth potential, supported by strong domestic consumption patterns and expanding export opportunities. The sector has successfully navigated global challenges while maintaining competitive positioning through strategic investments in technology and sustainability initiatives. Market fundamentals remain robust, with increasing consumer sophistication driving demand for higher-quality fabrics and innovative textile solutions.

Key performance indicators reveal positive trends across multiple segments, with synthetic fabrics showing particularly strong growth at 8.1% annually, while traditional textiles maintain steady demand. The market benefits from government support through favorable policies, infrastructure development, and trade facilitation measures. Digital transformation has accelerated market evolution, with e-commerce platforms and digital marketing strategies enhancing market reach and consumer engagement.

Strategic positioning within global supply chains has strengthened, with Indonesian manufacturers increasingly recognized as reliable partners for international brands and retailers. The market’s future trajectory appears promising, supported by demographic advantages, improving economic conditions, and ongoing industrial modernization efforts.

Market analysis reveals several critical insights shaping the Indonesia cloth market landscape:

Consumer behavior patterns indicate growing preference for quality over price, with middle-class expansion supporting premium segment growth. Regional variations in demand reflect diverse cultural preferences and economic conditions across Indonesia’s archipelago, creating opportunities for targeted market strategies.

Economic growth serves as the primary driver for Indonesia’s cloth market expansion, with rising disposable incomes enabling increased consumer spending on textile products. The country’s steady GDP growth has translated into improved living standards and greater demand for quality clothing and home textiles. Urbanization trends contribute significantly to market dynamics, as urban consumers typically demonstrate higher consumption rates and preference for modern textile products.

Population demographics provide substantial market support, with approximately 42% of the population under 25 years of age, creating sustained demand for fashion-forward and trendy textile products. This demographic advantage ensures long-term market growth potential as young consumers enter the workforce and establish independent households. Cultural factors also drive demand, particularly for traditional textiles during religious ceremonies, cultural celebrations, and formal occasions.

Government initiatives supporting the textile industry through infrastructure development, skill training programs, and export promotion activities have created favorable market conditions. Trade agreements and preferential access to international markets have enhanced export opportunities, while domestic policies promoting local textile consumption support internal market growth.

Competition challenges from established textile manufacturing countries, particularly China, Vietnam, and Bangladesh, create pricing pressures and market share concerns for Indonesian producers. These competitors often benefit from lower labor costs or more advanced manufacturing capabilities, requiring Indonesian companies to focus on differentiation strategies and value-added services.

Raw material dependencies pose significant constraints, as Indonesia relies heavily on imported cotton and synthetic fibers for textile production. Price volatility in global commodity markets can impact production costs and profit margins, affecting overall market competitiveness. Currency fluctuations also influence import costs and export competitiveness, creating uncertainty for market participants.

Infrastructure limitations in certain regions restrict market development and increase operational costs. Transportation challenges, power supply issues, and limited access to modern manufacturing facilities can hinder productivity improvements and market expansion efforts. Skilled labor shortages in specialized textile manufacturing processes also constrain growth potential and technological advancement.

Export expansion presents significant opportunities, particularly in emerging markets where Indonesian textile products can compete effectively on quality and price. The growing global demand for sustainable and ethically produced textiles aligns well with Indonesia’s capabilities in eco-friendly manufacturing processes. Market penetration in premium segments offers potential for higher profit margins and brand development.

Digital transformation creates opportunities for direct-to-consumer sales, online marketplace participation, and digital marketing initiatives. E-commerce growth enables smaller manufacturers to access broader markets without significant distribution investments. Technology adoption in manufacturing processes can improve efficiency, reduce costs, and enhance product quality, supporting competitive positioning.

Sustainable textile production represents a growing market opportunity, with increasing consumer awareness driving demand for environmentally responsible products. Indonesian manufacturers can leverage natural fiber resources and traditional production methods to develop unique sustainable textile offerings. Value chain integration opportunities exist for companies willing to invest in vertical integration from fiber production to finished garments.

Supply and demand dynamics in the Indonesia cloth market reflect complex interactions between domestic consumption patterns, export requirements, and production capabilities. Seasonal variations influence market activity, with peak demand periods coinciding with religious festivals, back-to-school seasons, and traditional celebration periods. These cyclical patterns require careful inventory management and production planning.

Price dynamics are influenced by multiple factors including raw material costs, labor expenses, energy prices, and competitive pressures. Market consolidation trends show larger manufacturers gaining market share through economies of scale and technological investments, while smaller producers focus on niche markets and specialized products. Innovation cycles drive product development, with manufacturers introducing new fabric types, treatments, and finishes to meet evolving consumer preferences.

Regulatory dynamics impact market operations through environmental standards, labor regulations, and trade policies. MarkWide Research analysis indicates that companies adapting quickly to regulatory changes maintain competitive advantages and market positioning. Global trade dynamics affect export opportunities and competitive positioning, requiring market participants to remain flexible and responsive to international market conditions.

Comprehensive market analysis employs multiple research methodologies to ensure accurate and reliable market insights. Primary research includes extensive interviews with industry executives, manufacturers, distributors, and key stakeholders across the Indonesian textile value chain. These interviews provide firsthand insights into market trends, challenges, and opportunities from industry participants’ perspectives.

Secondary research incorporates analysis of government statistics, industry reports, trade data, and economic indicators relevant to the Indonesian cloth market. Quantitative analysis examines production volumes, export-import data, pricing trends, and market share information from reliable sources. Qualitative assessment evaluates market dynamics, competitive positioning, and strategic developments affecting market evolution.

Data validation processes ensure information accuracy through cross-referencing multiple sources and expert verification. Market modeling techniques project future trends based on historical data, current market conditions, and identified growth drivers. Regional analysis examines market variations across different Indonesian provinces and economic zones to provide comprehensive market understanding.

Java region dominates Indonesia’s cloth market, accounting for approximately 68% of total production capacity and hosting major manufacturing centers in West Java, Central Java, and East Java provinces. This concentration reflects historical industrial development, infrastructure advantages, and proximity to major ports facilitating raw material imports and finished product exports. Jakarta metropolitan area serves as the primary commercial hub for textile trading and distribution activities.

Sumatra region represents the second-largest market segment, with 18% market share concentrated primarily in North Sumatra and South Sumatra provinces. The region benefits from palm oil industry synergies and growing consumer markets in major cities like Medan and Palembang. Manufacturing capabilities in Sumatra focus on cotton textiles and traditional fabric production.

Other regions including Kalimantan, Sulawesi, and eastern Indonesia collectively account for 14% of market activity, with growth potential driven by regional economic development and infrastructure improvements. Traditional textile production remains significant in regions like Bali, Lombok, and Flores, where cultural heritage supports specialized market segments. Government initiatives promoting industrial decentralization create opportunities for market expansion beyond traditional manufacturing centers.

Market leadership is distributed among several major Indonesian textile manufacturers and international companies with local operations. The competitive environment reflects diverse strategies ranging from cost leadership to differentiation and niche market focus.

Competitive strategies emphasize technological advancement, sustainability initiatives, and market diversification. International partnerships and joint ventures enable technology transfer and market access, while local companies leverage cultural understanding and cost advantages.

By Fabric Type:

By Application:

By End User:

Cotton fabric segment maintains strong market position due to consumer preference for natural fibers and comfort characteristics. Domestic cotton production limitations require significant imports, creating opportunities for value-added processing and finishing operations. Premium cotton fabrics show growing demand among affluent consumers seeking quality and durability.

Synthetic fabric category demonstrates the highest growth rates at 8.1% annually, driven by performance characteristics, cost advantages, and versatility in applications. Polyester fabrics dominate this segment, with increasing adoption in both apparel and technical applications. Innovation focus on sustainable synthetic materials addresses environmental concerns while maintaining performance benefits.

Traditional textile segment preserves cultural significance while adapting to modern market requirements. Batik fabrics experience renewed interest from younger consumers and international markets, supported by UNESCO recognition and government promotion. Artisan communities benefit from growing appreciation for handcrafted textiles and cultural authenticity.

Technical textiles represent an emerging high-value segment with 12.3% growth potential, driven by industrial development and infrastructure projects. Specialized applications in automotive, construction, and medical sectors create opportunities for manufacturers with advanced capabilities and quality certifications.

Manufacturers benefit from Indonesia’s competitive production costs, skilled workforce, and improving infrastructure supporting efficient operations. Raw material access through established supply chains and government support programs reduces procurement challenges. Technology advancement opportunities through partnerships and investment incentives enable productivity improvements and quality enhancements.

Investors gain from market growth potential, favorable regulatory environment, and government support for textile industry development. Export opportunities provide revenue diversification and growth prospects beyond domestic markets. Vertical integration possibilities create value chain optimization and margin improvement opportunities.

Consumers enjoy diverse product choices, competitive pricing, and improving quality standards across all market segments. Cultural preservation through traditional textile production maintains heritage while providing contemporary applications. Sustainable options address environmental concerns while supporting local communities and artisan traditions.

Government stakeholders benefit from employment generation, export earnings, and regional development contributions. Tax revenues and foreign exchange earnings support economic development objectives. Industrial diversification reduces economic dependence on commodity exports while building manufacturing capabilities.

Strengths:

Weaknesses:

Opportunities:

Threats:

Sustainability integration emerges as a dominant trend, with manufacturers adopting eco-friendly production processes, sustainable raw materials, and circular economy principles. Consumer awareness drives demand for environmentally responsible textile products, creating competitive advantages for companies implementing sustainable practices. Certification programs and sustainability standards become increasingly important for market access and brand positioning.

Digital transformation accelerates across the value chain, with e-commerce adoption reaching 23% of total sales in urban markets. Smart manufacturing technologies including automation, IoT sensors, and data analytics improve operational efficiency and product quality. Digital marketing strategies enable direct consumer engagement and brand building activities.

Customization trends reflect growing consumer demand for personalized products and unique designs. Small-batch production capabilities enable manufacturers to serve niche markets and premium segments effectively. Design innovation incorporates traditional motifs with contemporary styling, appealing to both domestic and international consumers.

Supply chain optimization focuses on reducing lead times, improving quality control, and enhancing traceability throughout the production process. Vertical integration strategies help companies control quality and costs while improving market responsiveness.

Technology investments by major manufacturers include advanced weaving equipment, automated dyeing systems, and digital printing capabilities. PT Sri Rejeki Isman completed a major expansion project incorporating Industry 4.0 technologies, improving production efficiency by 15%. Sustainability initiatives across the industry include water treatment facilities, renewable energy adoption, and waste reduction programs.

Government policy developments include the National Industrial Development Master Plan emphasizing textile sector growth and competitiveness improvement. Export promotion programs provide financial incentives and market access support for Indonesian textile manufacturers. Skill development initiatives through partnerships with educational institutions address workforce training needs.

International partnerships and joint ventures facilitate technology transfer and market expansion. European fashion brands increasingly source from Indonesian manufacturers, recognizing quality improvements and ethical production practices. Regional trade agreements enhance market access and competitive positioning in ASEAN markets.

Innovation centers and research facilities support product development and technology advancement. Collaboration programs between manufacturers and universities promote research and development activities focused on sustainable textiles and advanced materials.

Strategic recommendations for market participants emphasize the importance of sustainability integration, technology adoption, and market diversification. MarkWide Research analysis suggests that companies investing in sustainable production capabilities will gain competitive advantages as environmental regulations tighten and consumer preferences shift toward eco-friendly products.

Export market development should focus on emerging economies in Africa, Latin America, and Southeast Asia where Indonesian textile products can compete effectively. Quality improvement initiatives remain critical for accessing premium market segments and building long-term customer relationships. Brand development strategies can differentiate Indonesian textile products from low-cost competitors.

Technology adoption priorities include automation systems, digital printing capabilities, and sustainable production technologies. Workforce development programs should address skill gaps in technical areas and quality management. Supply chain optimization can reduce costs and improve market responsiveness through better inventory management and logistics coordination.

Government collaboration opportunities exist in infrastructure development, export promotion, and regulatory framework improvement. Industry associations should coordinate collective marketing efforts and technology sharing initiatives to strengthen overall sector competitiveness.

Market projections indicate sustained growth momentum for the Indonesia cloth market, supported by favorable demographic trends, economic development, and expanding export opportunities. Domestic consumption is expected to grow at 5.8% annually over the next five years, driven by rising incomes and urbanization trends. Export growth potential remains strong, particularly in sustainable textile segments and technical applications.

Technology advancement will continue reshaping the industry, with smart manufacturing, artificial intelligence, and sustainable production technologies becoming standard practices. Digital integration across the value chain will enhance efficiency, quality control, and customer engagement capabilities. Innovation focus on sustainable materials and circular economy principles will create new market opportunities.

Regional development initiatives will distribute manufacturing capabilities more evenly across Indonesia, reducing concentration in Java and creating opportunities in other provinces. Infrastructure improvements will support market expansion and operational efficiency enhancements. MWR forecasts indicate that companies adapting to these trends will achieve superior performance and market positioning.

International competitiveness will depend on successful implementation of sustainability practices, quality improvements, and technological advancement. Market consolidation may accelerate as larger companies acquire smaller manufacturers to achieve economies of scale and market expansion.

Indonesia’s cloth market demonstrates remarkable potential for sustained growth and development, supported by strong fundamentals including large domestic demand, competitive production capabilities, and expanding export opportunities. The market’s evolution reflects successful adaptation to global trends while preserving cultural heritage and traditional textile expertise that provides unique competitive advantages.

Strategic positioning within global supply chains continues to strengthen, with Indonesian manufacturers gaining recognition for quality, reliability, and sustainable production practices. Technology adoption and sustainability integration will remain critical success factors as the market evolves to meet changing consumer preferences and regulatory requirements. Government support and industry collaboration create favorable conditions for continued market expansion and competitiveness improvement.

Future success will depend on the industry’s ability to balance traditional strengths with modern requirements, leveraging cultural heritage while embracing innovation and technological advancement. The Indonesia cloth market is well-positioned to capitalize on emerging opportunities in sustainable textiles, digital commerce, and international trade, ensuring continued growth and prosperity for all stakeholders involved in this dynamic and evolving sector.

What is Cloth?

Cloth refers to a flexible material made from weaving or knitting fibers, commonly used in the production of garments, home textiles, and various industrial applications.

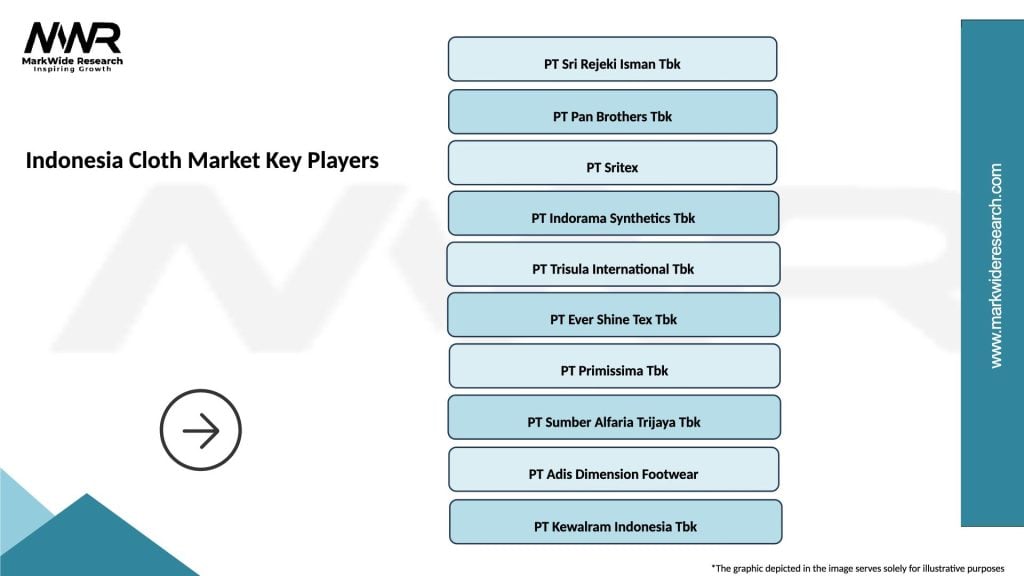

What are the key players in the Indonesia Cloth Market?

Key players in the Indonesia Cloth Market include PT. Sri Rejeki Isman Tbk, PT. Indorama Synthetics Tbk, and PT. Pan Brothers Tbk, among others.

What are the growth factors driving the Indonesia Cloth Market?

The growth of the Indonesia Cloth Market is driven by increasing consumer demand for fashion apparel, the rise of e-commerce platforms, and the expansion of textile manufacturing capabilities in the region.

What challenges does the Indonesia Cloth Market face?

Challenges in the Indonesia Cloth Market include competition from imported textiles, fluctuating raw material prices, and environmental regulations impacting production processes.

What opportunities exist in the Indonesia Cloth Market?

Opportunities in the Indonesia Cloth Market include the growing trend of sustainable fashion, the potential for export growth, and the increasing popularity of local textile brands.

What trends are shaping the Indonesia Cloth Market?

Trends in the Indonesia Cloth Market include the rise of eco-friendly fabrics, the integration of technology in textile production, and the shift towards online retailing for clothing sales.

Indonesia Cloth Market

| Segmentation Details | Description |

|---|---|

| Product Type | Cotton, Silk, Polyester, Wool |

| End User | Fashion Industry, Home Textiles, Upholstery, Industrial Applications |

| Distribution Channel | Online Retail, Wholesale, Direct Sales, Specialty Stores |

| Application | Apparel, Home Furnishings, Technical Textiles, Others |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the Indonesia Cloth Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at