444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2750

The South America Polyethylene Terephthalate (PET) market represents a dynamic and rapidly evolving sector within the region’s chemical and packaging industries. PET polymer has established itself as a cornerstone material across multiple applications, from beverage containers to textile fibers, driving substantial demand throughout Argentina, Brazil, Chile, Colombia, and other South American nations. The market demonstrates robust growth potential with expanding applications in food packaging, automotive components, and industrial materials.

Regional consumption patterns indicate strong demand from the beverage industry, which accounts for approximately 68% of total PET usage across South America. The market benefits from increasing urbanization, rising disposable incomes, and growing consumer preference for convenient packaging solutions. Brazil dominates the regional landscape, representing nearly 55% of South American PET consumption, followed by Argentina and Colombia as significant contributors to market expansion.

Manufacturing capabilities within the region have strengthened considerably, with local production facilities reducing dependence on imports and improving supply chain efficiency. The market experiences consistent growth driven by sustainable packaging initiatives and increasing adoption of recycled PET materials. Innovation trends focus on lightweight packaging solutions, enhanced barrier properties, and improved recyclability features that align with environmental regulations and consumer expectations.

The South America Polyethylene Terephthalate (PET) market refers to the comprehensive ecosystem encompassing production, distribution, and consumption of PET polymer materials across South American countries. PET represents a thermoplastic polymer resin belonging to the polyester family, characterized by excellent clarity, strength, and barrier properties that make it ideal for packaging applications.

Market scope includes various PET forms such as bottle-grade PET for beverage containers, food-grade PET for packaging applications, fiber-grade PET for textile production, and film-grade PET for flexible packaging solutions. The market encompasses both virgin PET production and recycled PET processing, reflecting growing emphasis on circular economy principles and sustainable material usage.

Value chain participants include raw material suppliers, PET resin manufacturers, converters, packaging companies, brand owners, and recycling facilities. The market serves diverse end-use industries including beverages, food packaging, textiles, automotive, electronics, and industrial applications, creating a multifaceted demand landscape that drives regional market dynamics.

Market fundamentals demonstrate strong growth trajectory supported by expanding beverage consumption, increasing packaging demand, and growing textile industry requirements across South America. The regional market benefits from strategic investments in production capacity, technological advancements in PET processing, and supportive government policies promoting local manufacturing capabilities.

Key growth drivers include rising consumer spending on packaged goods, expanding food and beverage industry, increasing export opportunities, and growing adoption of sustainable packaging solutions. The market shows resilience against economic fluctuations due to essential nature of PET applications and diversified end-use portfolio spanning multiple industries.

Competitive dynamics feature both international players and regional manufacturers competing through product innovation, cost optimization, and strategic partnerships. Market participants focus on expanding production capacity, improving product quality, and developing specialized PET grades to meet specific application requirements. Sustainability initiatives drive approximately 23% of new product development activities, emphasizing recycled content and improved recyclability features.

Future prospects remain positive with anticipated growth in packaging applications, expanding textile sector, and increasing adoption of PET in emerging applications such as automotive components and industrial materials. The market benefits from favorable demographic trends, urbanization patterns, and evolving consumer preferences toward convenient and sustainable packaging solutions.

Demand patterns reveal strong correlation between economic growth and PET consumption, with beverage packaging representing the largest application segment across all South American markets. Regional preferences vary significantly, with Brazil showing higher demand for large-format containers while smaller markets prefer single-serve packaging solutions.

Economic expansion across South America creates favorable conditions for PET market growth, with increasing industrial activity, rising consumer spending, and expanding middle-class population driving demand for packaged goods. Urbanization trends accelerate adoption of convenient packaging solutions, particularly in beverage and food applications where PET offers superior performance characteristics.

Beverage industry growth serves as the primary market driver, with expanding soft drink consumption, growing bottled water demand, and increasing preference for ready-to-drink products. The sector benefits from hot climate conditions across much of South America, seasonal consumption patterns, and evolving lifestyle preferences favoring portable beverage options.

Infrastructure development supports market expansion through improved transportation networks, enhanced distribution capabilities, and better access to raw materials. Government initiatives promoting local manufacturing, import substitution policies, and support for sustainable packaging solutions create positive regulatory environment for PET market development.

Technological advancements in PET processing enable production of lighter-weight containers, improved barrier properties, and enhanced recyclability features. These innovations reduce material costs, improve product performance, and align with sustainability objectives, driving adoption across multiple application segments.

Raw material volatility presents significant challenges for PET manufacturers, with fluctuating petroleum prices directly impacting production costs and profit margins. Supply chain dependencies on imported raw materials expose regional producers to currency fluctuations, transportation disruptions, and geopolitical uncertainties affecting cost structures.

Environmental concerns regarding plastic waste management create regulatory pressures and consumer resistance in certain segments. Waste management infrastructure limitations across many South American countries hinder effective PET recycling programs, potentially limiting long-term market sustainability and growth prospects.

Economic instability in key regional markets affects consumer spending patterns, industrial investment decisions, and overall demand for PET products. Currency devaluations increase costs for imported equipment and raw materials while reducing purchasing power for end-use applications, creating cyclical market pressures.

Competition from alternative materials including glass, aluminum, and bio-based polymers challenges PET market share in certain applications. Regulatory restrictions on single-use plastics and increasing emphasis on reusable packaging solutions may limit growth in specific market segments, requiring adaptation strategies from industry participants.

Recycling expansion presents substantial opportunities for market growth, with increasing demand for recycled PET content in packaging applications and government incentives supporting circular economy initiatives. Chemical recycling technologies enable processing of previously non-recyclable PET waste, expanding feedstock availability and reducing environmental impact.

Export market development offers significant potential for South American PET producers, with competitive manufacturing costs, strategic geographic location, and growing global demand for sustainable packaging solutions. Trade agreements facilitate market access to North American and European markets, creating opportunities for capacity expansion and revenue growth.

Application diversification beyond traditional packaging uses opens new market segments including automotive components, electronics housings, and industrial materials. Technical grade PET applications in engineering plastics, medical devices, and specialty films provide higher-value opportunities with improved profit margins.

Innovation partnerships between regional manufacturers and international technology providers enable access to advanced processing techniques, specialized product grades, and sustainable material solutions. Research collaborations with universities and research institutions support development of next-generation PET materials with enhanced performance characteristics.

Supply-demand equilibrium in the South American PET market reflects balanced growth between production capacity and consumption requirements, with regional manufacturers maintaining healthy utilization rates while meeting expanding demand. Market maturity varies significantly across countries, with Brazil and Argentina showing mature market characteristics while smaller economies demonstrate higher growth potential.

Competitive intensity drives continuous improvement in product quality, cost efficiency, and customer service levels. Price dynamics follow global petrochemical trends while incorporating regional factors such as transportation costs, local taxes, and currency fluctuations that influence final product pricing.

Technology adoption accelerates across the region, with manufacturers investing in advanced processing equipment, quality control systems, and automation technologies to improve competitiveness. Sustainability integration becomes increasingly important, with approximately 34% of market participants implementing comprehensive environmental management systems.

Market consolidation trends indicate potential for strategic acquisitions, joint ventures, and capacity expansion projects as companies seek to strengthen market positions and achieve economies of scale. Vertical integration strategies enable better cost control and supply chain optimization, particularly for large-scale producers serving multiple application segments.

Comprehensive market analysis employs multiple research methodologies to ensure accurate and reliable market insights for the South American PET market. Primary research includes extensive interviews with industry executives, manufacturers, distributors, and end-users across major South American countries to gather firsthand market intelligence and validate secondary research findings.

Secondary research encompasses analysis of industry reports, government statistics, trade association data, and company financial statements to establish market baselines and identify trends. Data triangulation methods ensure consistency and accuracy across multiple information sources, providing robust foundation for market analysis and forecasting.

Market modeling utilizes statistical analysis, regression techniques, and econometric methods to project future market trends and quantify growth opportunities. Scenario analysis evaluates potential market outcomes under different economic, regulatory, and competitive conditions to provide comprehensive market outlook.

Expert validation processes involve review by industry specialists, technical experts, and regional market analysts to ensure research findings accurately reflect market realities and provide actionable insights for stakeholders. Continuous monitoring systems track market developments and update analysis to maintain relevance and accuracy of research conclusions.

Brazil dominates the South American PET market with approximately 55% of regional consumption, driven by large population, developed beverage industry, and established manufacturing infrastructure. São Paulo serves as the primary industrial hub with major PET production facilities and extensive distribution networks serving domestic and export markets.

Argentina represents the second-largest market with strong demand from beverage, food packaging, and textile applications. Economic volatility creates cyclical demand patterns, but underlying market fundamentals remain solid with growing consumer base and expanding industrial applications supporting long-term growth prospects.

Colombia demonstrates rapid market expansion with increasing urbanization, rising disposable incomes, and growing beverage consumption driving PET demand. Strategic location provides access to both South American and North American markets, creating opportunities for regional manufacturing and export activities.

Chile and Peru show steady market growth supported by stable economies, expanding food and beverage sectors, and increasing adoption of modern packaging solutions. Mining industry presence in both countries creates additional demand for industrial PET applications and specialty products.

Smaller markets including Ecuador, Uruguay, and Bolivia demonstrate emerging opportunities with growing consumer markets, improving infrastructure, and increasing integration with regional supply chains. Market penetration rates remain below regional averages, indicating significant growth potential as economic conditions improve.

Market leadership features combination of international corporations and regional players competing across different market segments and geographic areas. Competitive strategies focus on capacity expansion, product innovation, cost optimization, and strategic partnerships to strengthen market positions and capture growth opportunities.

Competitive differentiation strategies include development of specialized product grades, implementation of sustainable manufacturing practices, and establishment of strategic customer partnerships. Market share dynamics remain relatively stable with gradual shifts based on capacity additions, technological improvements, and customer relationship management.

By Product Type: The market segments into bottle-grade PET, fiber-grade PET, film-grade PET, and engineering-grade PET, with bottle-grade representing the largest segment due to extensive beverage packaging applications. Fiber-grade PET shows strong growth potential driven by expanding textile industry and increasing demand for polyester fibers.

By Application: Beverage packaging dominates market segmentation, followed by food packaging, textile fibers, automotive components, and industrial applications. Packaging applications collectively account for approximately 78% of total market demand, reflecting the primary use of PET in consumer goods industries.

By End-Use Industry: Food and beverage industry represents the largest end-use segment, followed by textiles, automotive, electronics, and industrial manufacturing. Cross-industry applications demonstrate PET versatility and support market stability through diversified demand base.

By Technology: Conventional PET production maintains market dominance while bio-based PET and recycled PET technologies gain market share. Recycled content integration increases across all application segments, driven by sustainability requirements and cost considerations.

Bottle-Grade PET: Represents the largest market category with consistent demand from beverage industry and expanding applications in food packaging. Lightweighting trends drive innovation in bottle design and material optimization, reducing PET consumption per unit while maintaining performance characteristics. Quality requirements focus on clarity, barrier properties, and processing stability.

Fiber-Grade PET: Shows robust growth driven by textile industry expansion and increasing demand for polyester fibers in apparel, home textiles, and industrial applications. Recycled content integration reaches 28% in fiber applications, supporting circular economy objectives while meeting performance requirements for various textile applications.

Film-Grade PET: Demonstrates steady growth in flexible packaging, industrial films, and specialty applications requiring excellent mechanical properties and chemical resistance. Technical innovations focus on enhanced barrier properties, improved heat resistance, and specialized surface treatments for specific applications.

Engineering-Grade PET: Emerges as high-value segment with applications in automotive components, electronics housings, and industrial parts. Performance modifications through additives and processing techniques enable PET use in demanding applications previously dominated by other engineering plastics.

Manufacturers benefit from growing market demand, expanding application opportunities, and improving profit margins through operational efficiency and product innovation. Economies of scale enable cost reduction while technological advancements support product differentiation and premium pricing strategies.

Brand owners gain access to versatile packaging solutions offering excellent product protection, consumer appeal, and sustainability credentials. PET packaging provides optimal balance of performance, cost-effectiveness, and environmental responsibility, supporting brand positioning and market competitiveness.

Consumers benefit from improved product quality, enhanced convenience, and better environmental outcomes through recyclable packaging solutions. Lightweight packaging reduces transportation costs and environmental impact while maintaining product integrity and safety standards.

Recycling industry participants capitalize on growing demand for recycled PET content and expanding collection infrastructure. Circular economy initiatives create new revenue streams while supporting environmental objectives and regulatory compliance requirements.

Regional economies benefit from job creation, industrial development, and reduced import dependence through local PET production capacity. Export opportunities generate foreign exchange earnings while supporting regional economic growth and industrial competitiveness.

Strengths:

Weaknesses:

Opportunities:

Threats:

Sustainability Integration emerges as dominant trend with increasing adoption of recycled PET content, development of bio-based alternatives, and implementation of circular economy principles across the value chain. Consumer awareness drives demand for environmentally responsible packaging solutions, influencing product development and marketing strategies.

Lightweighting Innovation continues advancing with development of thinner-wall containers, optimized bottle designs, and improved material efficiency. Technology improvements enable production of lighter packaging while maintaining structural integrity and barrier properties, reducing material costs and environmental impact.

Digital Integration transforms manufacturing operations through implementation of Industry 4.0 technologies, predictive maintenance systems, and automated quality control processes. Data analytics optimize production efficiency, reduce waste, and improve product consistency across manufacturing facilities.

Regional Consolidation accelerates through strategic acquisitions, joint ventures, and capacity expansion projects as companies seek economies of scale and market leadership positions. Vertical integration strategies enable better supply chain control and cost optimization opportunities.

Specialty Applications growth drives development of high-performance PET grades for automotive, electronics, and industrial applications. Technical innovation focuses on enhanced properties such as heat resistance, chemical compatibility, and mechanical strength for demanding applications.

Capacity Expansion Projects across major South American markets indicate strong industry confidence and growing demand expectations. Recent investments focus on modernizing existing facilities, implementing advanced technologies, and expanding production capabilities to serve domestic and export markets.

Recycling Infrastructure Development accelerates with new collection systems, sorting facilities, and chemical recycling plants supporting circular economy objectives. Government initiatives provide incentives for recycling investments while regulatory frameworks encourage sustainable packaging practices.

Technology Partnerships between regional manufacturers and international technology providers enable access to advanced processing techniques and specialized product development capabilities. Knowledge transfer programs support local technical expertise development and innovation capacity building.

Sustainability Certifications gain importance with increasing adoption of environmental management systems, carbon footprint reduction programs, and sustainable sourcing practices. Industry standards evolve to address environmental concerns while maintaining product quality and performance requirements.

Market Consolidation Activities include strategic acquisitions, joint ventures, and partnership agreements aimed at strengthening market positions and achieving operational synergies. Cross-border investments facilitate technology transfer and market access expansion opportunities.

MarkWide Research recommends that industry participants focus on sustainability initiatives as key differentiator in competitive marketplace. Investment priorities should emphasize recycling capabilities, energy efficiency improvements, and development of bio-based alternatives to address evolving market requirements and regulatory expectations.

Strategic partnerships with technology providers, research institutions, and downstream customers enable access to innovation capabilities and market intelligence necessary for long-term competitiveness. Collaboration opportunities should focus on developing next-generation PET materials and sustainable packaging solutions.

Market diversification beyond traditional packaging applications reduces dependence on cyclical beverage industry demand while capturing higher-value opportunities in technical applications. Application development in automotive, electronics, and industrial segments provides growth potential and margin improvement opportunities.

Operational excellence through digital transformation, automation implementation, and continuous improvement programs enhances competitiveness and profitability. Technology adoption should prioritize solutions that improve efficiency, reduce costs, and enhance product quality consistency.

Regional integration strategies enable better market coverage, supply chain optimization, and risk diversification across South American markets. Cross-border expansion opportunities should consider regulatory environments, competitive dynamics, and customer requirements in target markets.

Market prospects remain positive with anticipated growth driven by expanding beverage consumption, increasing packaging demand, and growing adoption of sustainable materials. Long-term trends support continued market expansion despite short-term economic uncertainties and competitive pressures affecting regional markets.

Technology evolution will continue driving innovation in PET processing, recycling, and application development. Advanced recycling technologies enable processing of previously non-recyclable materials while bio-based alternatives provide sustainable feedstock options for future production growth.

Regulatory environment evolution toward stricter environmental standards and circular economy requirements will reshape market dynamics and competitive strategies. Compliance capabilities become increasingly important for market access and customer acceptance in environmentally conscious market segments.

Regional integration opportunities through trade agreements and economic cooperation initiatives support market expansion and export development. MWR analysis indicates that South American PET producers are well-positioned to capitalize on global market opportunities through competitive cost structures and strategic geographic location.

Innovation focus on sustainable materials, advanced processing technologies, and specialized applications will drive future market differentiation and value creation. Investment in research and development capabilities becomes critical for maintaining competitiveness in evolving market landscape.

The South America Polyethylene Terephthalate (PET) market demonstrates robust fundamentals and positive growth trajectory supported by expanding applications, improving production capabilities, and growing emphasis on sustainable packaging solutions. Market dynamics reflect balanced supply-demand conditions with opportunities for capacity expansion, technology advancement, and application diversification across the region.

Industry transformation toward sustainability, digitalization, and operational excellence creates both challenges and opportunities for market participants. Successful companies will be those that effectively integrate environmental responsibility, technological innovation, and customer-focused strategies to capture emerging market opportunities while maintaining competitive cost structures.

Regional advantages including competitive manufacturing costs, strategic location, and growing domestic markets position South American PET producers favorably for both domestic growth and export expansion. Future success depends on continued investment in technology, sustainability initiatives, and market development activities that align with evolving customer requirements and regulatory expectations.

What is Polyethylene Terephthalate (PET)?

Polyethylene Terephthalate (PET) is a type of plastic commonly used in packaging, textiles, and containers. It is known for its strength, thermal stability, and resistance to moisture, making it ideal for various applications.

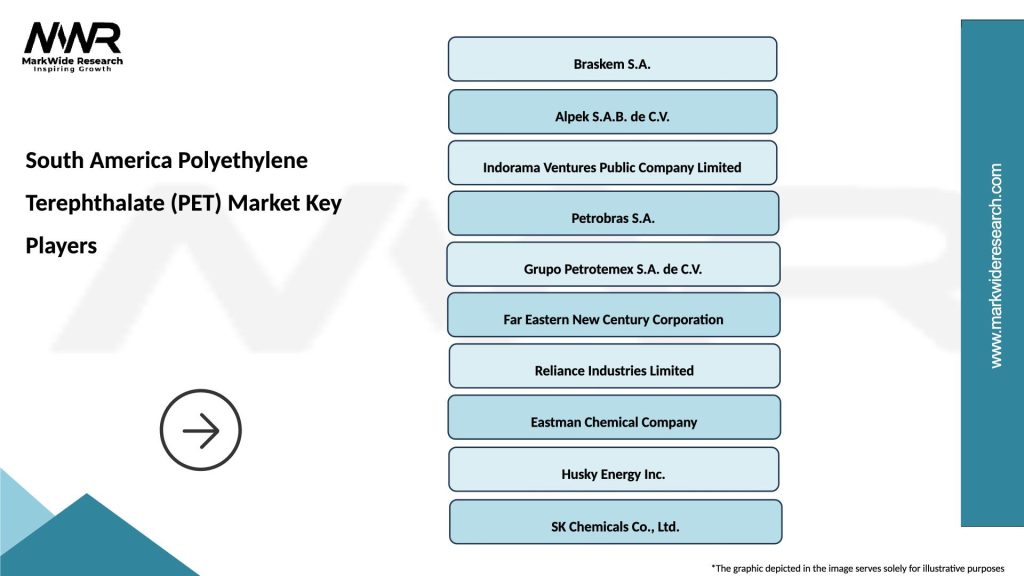

What are the key players in the South America Polyethylene Terephthalate (PET) Market?

Key players in the South America Polyethylene Terephthalate (PET) Market include companies like Braskem, Alpek, and Indorama Ventures, which are involved in the production and distribution of PET products, among others.

What are the growth factors driving the South America Polyethylene Terephthalate (PET) Market?

The growth of the South America Polyethylene Terephthalate (PET) Market is driven by increasing demand for sustainable packaging solutions, the rise in beverage consumption, and the expansion of the textile industry.

What challenges does the South America Polyethylene Terephthalate (PET) Market face?

The South America Polyethylene Terephthalate (PET) Market faces challenges such as fluctuating raw material prices, environmental concerns regarding plastic waste, and competition from alternative materials.

What opportunities exist in the South America Polyethylene Terephthalate (PET) Market?

Opportunities in the South America Polyethylene Terephthalate (PET) Market include the development of bio-based PET, innovations in recycling technologies, and increasing investments in sustainable production methods.

What trends are shaping the South America Polyethylene Terephthalate (PET) Market?

Trends in the South America Polyethylene Terephthalate (PET) Market include a growing focus on circular economy practices, advancements in PET recycling processes, and the rising popularity of lightweight packaging solutions.

South America Polyethylene Terephthalate (PET) Market

| Segmentation Details | Description |

|---|---|

| Product Type | Injection Molding, Blow Molding, Extrusion, Thermoforming |

| Grade | Food Grade, Industrial Grade, Recycled Grade, High Purity |

| Application | Bottles, Containers, Films, Fibers |

| End Use Industry | Packaging, Textiles, Automotive, Electronics |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the South America Polyethylene Terephthalate (PET) Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at