444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2750

The Latin America plastic packaging films market represents a dynamic and rapidly evolving sector within the region’s packaging industry. This market encompasses a diverse range of flexible packaging solutions including polyethylene films, polypropylene films, polyester films, and specialty barrier films used across multiple industries. Market growth is driven by increasing consumer demand for convenient packaging, expanding food and beverage sectors, and growing e-commerce activities throughout Latin American countries.

Regional dynamics show significant variation across Latin America, with Brazil and Mexico leading market consumption at approximately 45% combined market share. The market demonstrates strong resilience despite economic fluctuations, supported by essential applications in food preservation, pharmaceutical packaging, and industrial applications. Sustainability trends are increasingly influencing product development, with manufacturers investing in biodegradable and recyclable film technologies to meet evolving environmental regulations.

Growth projections indicate the market will expand at a 6.2% CAGR through the forecast period, driven by urbanization, changing consumer lifestyles, and increased adoption of flexible packaging solutions. The region’s strategic position as a manufacturing hub for multinational corporations further strengthens market prospects, creating opportunities for both local and international plastic film producers.

The Latin America plastic packaging films market refers to the comprehensive ecosystem of flexible plastic film materials designed for packaging applications across various industries within Latin American countries. These films serve as protective barriers, preserving product quality, extending shelf life, and providing convenient packaging solutions for consumers and businesses throughout the region.

Plastic packaging films encompass multiple polymer types including low-density polyethylene (LDPE), high-density polyethylene (HDPE), polypropylene (PP), polyethylene terephthalate (PET), and specialized multi-layer barrier films. These materials are engineered to provide specific properties such as moisture resistance, oxygen barrier capabilities, heat sealability, and printability to meet diverse packaging requirements across food, pharmaceutical, personal care, and industrial applications.

Market scope includes both monolayer and multilayer film structures, ranging from basic commodity films to sophisticated barrier packaging solutions. The market serves critical functions in food preservation, pharmaceutical protection, agricultural applications, and consumer goods packaging, making it an essential component of Latin America’s packaging value chain and broader economic infrastructure.

Market performance in Latin America’s plastic packaging films sector demonstrates robust growth momentum, supported by expanding end-user industries and evolving consumer preferences. The market benefits from strong domestic demand in key countries including Brazil, Mexico, Argentina, Colombia, and Chile, while also serving as a regional manufacturing hub for export markets.

Key growth drivers include rapid urbanization affecting 78% of the regional population, increasing disposable incomes, and growing demand for convenient packaging solutions. The food and beverage sector represents the largest application segment, accounting for approximately 55% of total consumption, followed by pharmaceutical and personal care applications. E-commerce expansion has created additional demand for protective packaging films, particularly in urban markets.

Technological advancement focuses on developing sustainable packaging solutions, with manufacturers investing in bio-based materials and improved recycling technologies. Market consolidation continues as regional players seek to enhance production capabilities and expand geographic reach. Regulatory compliance regarding food safety and environmental standards drives innovation in film formulations and manufacturing processes, creating opportunities for premium product segments.

Market segmentation reveals distinct patterns across Latin American countries, with varying preferences for film types and applications. The following insights highlight critical market characteristics:

Economic growth across Latin America creates favorable conditions for plastic packaging films market expansion. Rising disposable incomes and changing consumer lifestyles drive demand for convenient, portable packaging solutions across multiple product categories. Urbanization trends significantly impact packaging requirements, with urban consumers preferring ready-to-eat foods and single-serving packages that rely heavily on flexible film packaging.

Food industry expansion represents the primary market driver, with growing processed food consumption requiring advanced packaging solutions. The region’s agricultural abundance creates opportunities for value-added food processing, increasing demand for barrier films that preserve freshness and extend shelf life. Export agriculture particularly benefits from high-performance packaging films that maintain product quality during international transportation.

E-commerce growth accelerates demand for protective packaging films, especially in countries with expanding online retail markets. The pharmaceutical sector’s expansion, driven by aging populations and improved healthcare access, creates sustained demand for specialized packaging films meeting stringent regulatory requirements. Manufacturing investment by multinational corporations establishes Latin America as a regional production hub, increasing local demand for industrial packaging applications.

Environmental concerns pose significant challenges to the plastic packaging films market, with increasing regulatory pressure and consumer awareness regarding plastic waste. Government initiatives promoting plastic reduction and improved recycling create compliance costs and require substantial investment in alternative materials development. Raw material volatility affects production costs, with petroleum-based polymer prices subject to global oil market fluctuations.

Economic instability in certain Latin American countries creates market uncertainty, affecting investment decisions and consumer spending patterns. Currency fluctuations impact import costs for specialized additives and equipment, while inflation pressures affect overall packaging demand. Infrastructure limitations in some regions constrain market development, particularly regarding waste management and recycling capabilities.

Competition from alternative packaging materials, including paper-based solutions and rigid packaging, challenges market share in specific applications. Technological barriers limit local manufacturers’ ability to produce high-performance barrier films, creating dependence on imports for premium applications. Regulatory complexity across different Latin American countries increases compliance costs and complicates regional market strategies for manufacturers.

Sustainability innovation presents significant opportunities for market expansion, with growing demand for biodegradable, compostable, and recyclable packaging films. Companies investing in bio-based polymer technologies and circular economy solutions position themselves advantageously for future growth. Premium applications in pharmaceutical and medical device packaging offer higher margins and stable demand patterns.

Agricultural modernization across Latin America creates opportunities for specialized films including greenhouse covers, mulch films, and crop protection applications. The region’s agricultural export focus drives demand for high-performance packaging that maintains product quality during extended transportation. Technology transfer from developed markets enables local manufacturers to upgrade capabilities and serve premium market segments.

Regional integration initiatives facilitate cross-border trade and create larger addressable markets for efficient manufacturers. Export opportunities to North America and Europe leverage Latin America’s competitive manufacturing costs and improving quality standards. Digital printing technologies enable smaller production runs and customized packaging solutions, opening new market segments for flexible packaging converters.

Supply chain dynamics in the Latin America plastic packaging films market reflect complex interactions between raw material suppliers, film manufacturers, converters, and end-users. Regional polymer production capabilities influence market competitiveness, with countries like Brazil and Mexico developing integrated petrochemical complexes that support local film manufacturing. Logistics optimization becomes increasingly important as manufacturers seek to serve diverse geographic markets efficiently.

Competitive dynamics show ongoing consolidation as larger players acquire regional manufacturers to expand market reach and production capabilities. Technology partnerships between international and local companies facilitate knowledge transfer and capability development. Customer relationships evolve toward longer-term partnerships, with film suppliers providing technical support and customized solutions to major end-users.

Innovation cycles accelerate as market demands shift toward sustainable and high-performance solutions. Research and development investments focus on barrier enhancement, sustainability improvements, and cost optimization. Market responsiveness to regulatory changes and consumer preferences drives continuous product development and manufacturing process improvements throughout the regional market.

Comprehensive market analysis employs multiple research methodologies to ensure accurate and reliable market insights. Primary research includes extensive interviews with industry executives, manufacturers, converters, and end-users across major Latin American markets. Secondary research incorporates industry reports, government statistics, trade association data, and company financial statements to validate market trends and projections.

Data collection spans quantitative and qualitative approaches, including market surveys, production statistics, trade flow analysis, and regulatory impact assessments. Regional market variations receive particular attention, with country-specific analysis covering Brazil, Mexico, Argentina, Colombia, Chile, and other significant markets. Industry expert consultation provides insights into technological trends, competitive dynamics, and future market developments.

Market modeling incorporates economic indicators, demographic trends, and industry-specific factors to generate accurate growth projections. Cross-validation techniques ensure data consistency and reliability across different information sources. Continuous monitoring of market developments enables real-time updates to market assessments and strategic recommendations for industry participants.

Brazil maintains market leadership with sophisticated manufacturing capabilities and diverse end-user industries. The country’s large domestic market supports economies of scale, while agricultural exports drive demand for high-performance packaging films. Manufacturing infrastructure includes both multinational and domestic producers, creating competitive market dynamics and technological advancement.

Mexico benefits from proximity to North American markets and strong manufacturing sector growth. The country’s strategic location facilitates export opportunities while domestic demand grows across food, pharmaceutical, and industrial applications. NAFTA/USMCA benefits enhance Mexico’s competitiveness in serving regional markets with integrated supply chains.

Argentina demonstrates strong agricultural packaging demand, particularly for grain and meat export applications. Economic volatility creates challenges but also opportunities for import substitution. Colombia and Chile show steady growth in food packaging applications, supported by expanding middle-class populations and improved retail infrastructure. Regional market share distribution shows 65% concentration in Brazil and Mexico combined, with remaining countries representing emerging opportunities for market expansion.

Market leadership includes both international corporations and strong regional players competing across different market segments. The competitive environment demonstrates ongoing consolidation and strategic partnerships to enhance market position and technological capabilities.

Competitive strategies focus on technological innovation, geographic expansion, and vertical integration to enhance market position. Companies invest in sustainable packaging solutions and advanced barrier technologies to differentiate their offerings and capture premium market segments.

By Material Type:

By Application:

By End-User Industry:

Food packaging films demonstrate the strongest growth momentum, driven by expanding processed food consumption and export agriculture. Barrier films for meat, dairy, and snack food applications show particular strength, with manufacturers investing in advanced multi-layer technologies. Sustainability requirements increasingly influence product development, with recyclable and compostable options gaining market traction.

Pharmaceutical packaging represents a high-value segment with stringent regulatory requirements and stable demand patterns. Growth drivers include aging populations, expanded healthcare access, and increasing pharmaceutical manufacturing in the region. Blister packaging films and sterile barrier applications demonstrate consistent growth across major markets.

Agricultural films benefit from Latin America’s agricultural modernization and export focus. Greenhouse films, mulch applications, and crop protection solutions show strong growth potential. Technology adoption in agriculture drives demand for specialized films with enhanced durability and performance characteristics. Industrial applications maintain steady demand, supported by manufacturing sector growth and infrastructure development across the region.

Manufacturers benefit from growing regional demand and opportunities for capacity expansion. The market’s diversity across applications and countries provides risk mitigation through portfolio diversification. Technology advancement opportunities enable manufacturers to develop competitive advantages through innovation in sustainable materials and high-performance applications.

Converters and processors gain from expanding market opportunities and closer relationships with end-users. Regional manufacturing capabilities reduce logistics costs and improve customer service. Supply chain integration opportunities enable converters to enhance value-added services and strengthen customer relationships.

End-users benefit from improved packaging solutions that enhance product protection, extend shelf life, and reduce overall packaging costs. Access to advanced barrier technologies and sustainable packaging options supports brand differentiation and regulatory compliance. Local sourcing opportunities reduce supply chain risks and support cost optimization strategies for major consumer goods companies operating in Latin America.

Strengths:

Weaknesses:

Opportunities:

Threats:

Sustainability transformation represents the most significant trend affecting the Latin America plastic packaging films market. Manufacturers increasingly invest in bio-based materials, improved recyclability, and circular economy solutions. Consumer awareness drives demand for environmentally responsible packaging, creating opportunities for innovative companies while challenging traditional approaches.

Digital printing integration enables shorter production runs and customized packaging solutions, particularly benefiting small and medium-sized converters. This trend supports brand differentiation and reduces inventory requirements for end-users. Smart packaging technologies incorporating sensors and indicators gain traction in pharmaceutical and food applications, adding value through enhanced functionality.

Supply chain localization accelerates as companies seek to reduce logistics costs and improve responsiveness to local market needs. This trend benefits regional manufacturers while creating challenges for import-dependent market segments. Vertical integration strategies become more common as companies seek to control quality and costs throughout the value chain, according to MarkWide Research analysis of market developments.

Capacity expansion projects across major Latin American markets demonstrate industry confidence in long-term growth prospects. Several multinational corporations announce significant investments in regional manufacturing facilities, particularly in Brazil and Mexico. Technology upgrades focus on improving barrier properties, sustainability characteristics, and production efficiency.

Merger and acquisition activity continues as companies seek to strengthen market positions and expand geographic reach. Regional consolidation creates larger, more competitive companies capable of serving diverse market requirements. Partnership agreements between international technology providers and local manufacturers facilitate knowledge transfer and capability development.

Regulatory developments across Latin American countries increasingly focus on environmental impact and food safety requirements. New standards for recyclable content and biodegradable materials drive product innovation and manufacturing process changes. Industry associations work to harmonize standards across countries and promote sustainable packaging practices throughout the region.

Strategic positioning should emphasize sustainability leadership and technological innovation to capture premium market segments. Companies investing early in bio-based materials and advanced recycling technologies will gain competitive advantages as environmental regulations tighten. Market diversification across applications and geographic regions provides risk mitigation and growth opportunities.

Operational excellence becomes increasingly important as market competition intensifies. Manufacturers should focus on cost optimization, quality improvement, and customer service enhancement to maintain market position. Supply chain optimization through vertical integration or strategic partnerships can improve margins and market responsiveness.

Innovation investment in barrier technologies, sustainable materials, and smart packaging solutions will differentiate successful companies from commodity producers. MarkWide Research recommends focusing on high-growth segments including pharmaceutical packaging, premium food applications, and agricultural films. Companies should also consider export market development to leverage regional manufacturing advantages and access larger addressable markets.

Long-term growth prospects for the Latin America plastic packaging films market remain positive, supported by demographic trends, economic development, and expanding end-user industries. The market is expected to maintain a 6.2% CAGR growth trajectory, with sustainability-focused products showing above-average growth rates. Technology evolution will continue driving product innovation and market differentiation opportunities.

Sustainability transformation will accelerate, with bio-based and recyclable films gaining significant market share over the forecast period. Regulatory pressure and consumer preferences will drive this transition, creating opportunities for innovative companies while challenging traditional approaches. Circular economy principles will become integral to business strategies and product development processes.

Regional integration will strengthen as trade agreements facilitate cross-border commerce and supply chain optimization. Export opportunities will expand as Latin American manufacturers improve quality standards and develop competitive advantages in specific market segments. MWR projects that successful companies will be those that combine operational excellence with sustainability leadership and technological innovation, positioning themselves for long-term success in an evolving market landscape.

The Latin America plastic packaging films market presents a compelling combination of growth opportunities and strategic challenges. Strong regional demand driven by economic development, urbanization, and expanding end-user industries creates a favorable foundation for market expansion. However, increasing environmental awareness and regulatory pressure require industry adaptation toward more sustainable solutions.

Market success will increasingly depend on companies’ ability to balance traditional performance requirements with sustainability objectives. Innovation in bio-based materials, recyclable films, and circular economy solutions will differentiate market leaders from commodity producers. Regional manufacturing advantages and growing export opportunities provide additional growth avenues for competitive companies.

Strategic positioning should emphasize technological innovation, operational excellence, and sustainability leadership to capture the most attractive market opportunities. The market’s diversity across applications, materials, and geographic regions offers multiple pathways for growth and risk mitigation. Companies that successfully navigate the transition toward sustainable packaging while maintaining cost competitiveness and performance standards will be best positioned for long-term success in this dynamic and evolving market.

What is Plastic Packaging Films?

Plastic packaging films are thin layers of plastic used for wrapping and protecting products. They are commonly utilized in various applications, including food packaging, medical supplies, and consumer goods.

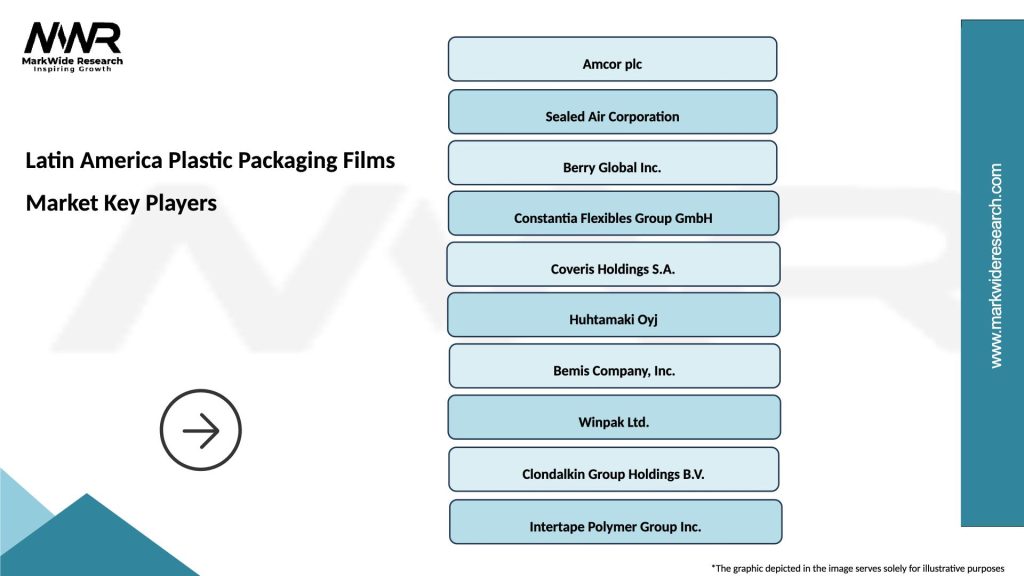

What are the key players in the Latin America Plastic Packaging Films Market?

Key players in the Latin America Plastic Packaging Films Market include Amcor, Sealed Air Corporation, and Berry Global, among others. These companies are known for their innovative packaging solutions and extensive distribution networks.

What are the main drivers of growth in the Latin America Plastic Packaging Films Market?

The growth of the Latin America Plastic Packaging Films Market is driven by increasing demand for convenient packaging solutions, the rise of e-commerce, and the need for sustainable packaging options. Additionally, the food and beverage industry significantly contributes to this demand.

What challenges does the Latin America Plastic Packaging Films Market face?

The Latin America Plastic Packaging Films Market faces challenges such as regulatory pressures regarding plastic waste, competition from alternative materials, and fluctuating raw material prices. These factors can impact production costs and market dynamics.

What opportunities exist in the Latin America Plastic Packaging Films Market?

Opportunities in the Latin America Plastic Packaging Films Market include the development of biodegradable films, advancements in recycling technologies, and the growing trend of sustainable packaging. Companies are increasingly focusing on eco-friendly solutions to meet consumer demands.

What trends are shaping the Latin America Plastic Packaging Films Market?

Trends in the Latin America Plastic Packaging Films Market include the shift towards lightweight and flexible packaging, the integration of smart packaging technologies, and the increasing use of recycled materials. These trends reflect a broader movement towards sustainability and innovation in packaging.

Latin America Plastic Packaging Films Market

| Segmentation Details | Description |

|---|---|

| Product Type | Stretch Films, Shrink Films, Barrier Films, Rigid Films |

| Application | Food Packaging, Medical Packaging, Industrial Packaging, Consumer Goods Packaging |

| Material | Polyethylene, Polypropylene, Polyvinyl Chloride, Biodegradable Plastics |

| End User | Food & Beverage, Healthcare, Retail, Electronics |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the Latin America Plastic Packaging Films Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at