444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

The Saudi Arabia flexible plastic packaging market represents a dynamic and rapidly evolving sector within the Kingdom’s expanding manufacturing and consumer goods landscape. Flexible plastic packaging has emerged as a cornerstone of modern packaging solutions, offering superior barrier properties, cost-effectiveness, and versatility across multiple industries. The market encompasses a comprehensive range of products including pouches, bags, films, wraps, and specialized packaging solutions designed to meet the diverse needs of food and beverage, pharmaceutical, personal care, and industrial sectors.

Market dynamics in Saudi Arabia are particularly influenced by the Kingdom’s Vision 2030 initiative, which emphasizes economic diversification and the development of local manufacturing capabilities. The flexible plastic packaging sector has experienced robust growth driven by increasing consumer demand for convenient packaging solutions, expanding retail infrastructure, and growing awareness of product preservation technologies. Industry analysts project sustained expansion with the market demonstrating 8.5% CAGR over the forecast period, reflecting strong domestic consumption patterns and export potential.

Regional positioning within the Gulf Cooperation Council (GCC) has established Saudi Arabia as a key hub for flexible packaging manufacturing and distribution. The Kingdom’s strategic location, coupled with significant investments in petrochemical infrastructure, provides competitive advantages in raw material availability and cost optimization. Manufacturing capabilities have expanded substantially, with local production accounting for approximately 72% of domestic consumption, reducing import dependency and enhancing supply chain resilience.

The Saudi Arabia flexible plastic packaging market refers to the comprehensive ecosystem of manufacturing, distribution, and consumption of flexible plastic-based packaging solutions within the Kingdom’s borders. Flexible plastic packaging encompasses packaging materials that can be readily shaped, bent, or formed without breaking, including multilayer films, pouches, bags, wraps, and specialized barrier packaging designed to protect, preserve, and present various consumer and industrial products.

Market scope includes both primary packaging that directly contacts products and secondary packaging used for distribution and retail presentation. The sector encompasses various plastic polymer types including polyethylene (PE), polypropylene (PP), polyethylene terephthalate (PET), and specialized barrier materials designed for specific applications. Technological integration within this market includes advanced printing capabilities, barrier enhancement technologies, and sustainable packaging innovations that align with global environmental standards.

Economic significance extends beyond packaging functionality to encompass supply chain optimization, brand differentiation, and consumer convenience enhancement. The market serves as a critical enabler for various industries including food processing, pharmaceuticals, personal care, and industrial manufacturing, providing essential packaging solutions that ensure product integrity, extend shelf life, and facilitate efficient distribution across Saudi Arabia’s vast geographic landscape.

Strategic positioning of the Saudi Arabia flexible plastic packaging market reflects the Kingdom’s broader economic transformation and industrial diversification objectives. The market has demonstrated exceptional resilience and growth potential, driven by fundamental shifts in consumer behavior, retail modernization, and manufacturing sector expansion. Key performance indicators suggest sustained market momentum with domestic production capabilities expanding to meet 85% of local demand by the forecast period end.

Investment landscape has attracted significant capital from both domestic and international players, with major petrochemical companies leveraging Saudi Arabia’s competitive advantages in raw material availability and energy costs. The market benefits from government support through various initiatives including industrial development programs, export promotion schemes, and technology transfer partnerships that enhance local manufacturing capabilities and innovation adoption.

Competitive dynamics feature a balanced mix of established international players and emerging local manufacturers, creating a robust ecosystem that promotes innovation, quality improvement, and cost optimization. Market consolidation trends indicate strategic partnerships and joint ventures designed to enhance technological capabilities, expand product portfolios, and strengthen distribution networks across the Kingdom and broader regional markets.

Future trajectory points toward increased sophistication in packaging solutions, with growing emphasis on sustainability, smart packaging technologies, and customized solutions that address specific industry requirements. The market is positioned to capitalize on Saudi Arabia’s strategic location as a gateway to regional and international markets, supported by ongoing infrastructure investments and trade facilitation initiatives.

Fundamental market drivers reveal several critical insights that shape the Saudi Arabia flexible plastic packaging landscape. Consumer behavior evolution has accelerated demand for convenient, portable, and aesthetically appealing packaging solutions that align with modern lifestyle preferences and shopping patterns. The rise of e-commerce and online retail has created new packaging requirements focused on product protection during transportation and enhanced unboxing experiences.

Economic diversification initiatives under Saudi Arabia’s Vision 2030 program serve as a primary catalyst for flexible plastic packaging market expansion. The Kingdom’s strategic focus on developing non-oil sectors, including manufacturing and consumer goods, creates substantial demand for sophisticated packaging solutions that support product quality, brand positioning, and market competitiveness. Industrial development programs provide incentives for local manufacturing establishment and capacity expansion, attracting both domestic and international investment in packaging infrastructure.

Demographic trends significantly influence market dynamics, with a young, increasingly urbanized population driving demand for convenient, portable packaging solutions. Lifestyle changes associated with urbanization, including increased participation in the workforce and changing household structures, create preferences for ready-to-eat foods, portion-controlled packaging, and on-the-go consumption formats that rely heavily on flexible plastic packaging technologies.

Retail sector modernization represents another crucial driver, with expanding supermarket chains, hypermarkets, and convenience stores requiring sophisticated packaging solutions that enhance product presentation, extend shelf life, and facilitate efficient inventory management. The growth of organized retail creates demand for standardized packaging formats, improved barrier properties, and enhanced visual appeal that supports brand differentiation and consumer choice.

Food processing industry expansion drives substantial demand for flexible packaging solutions, particularly as Saudi Arabia develops its agricultural processing capabilities and reduces reliance on food imports. Local food production growth necessitates advanced packaging technologies that ensure product safety, extend shelf life, and maintain quality during distribution across the Kingdom’s extensive geographic area.

Environmental concerns regarding plastic waste and sustainability represent significant challenges for the flexible plastic packaging market in Saudi Arabia. Growing global awareness of environmental issues and increasing regulatory pressure for sustainable packaging solutions create constraints on traditional plastic packaging applications. Consumer consciousness about environmental impact influences purchasing decisions and drives demand for alternative packaging materials, potentially limiting market expansion in certain segments.

Raw material price volatility poses ongoing challenges for market participants, particularly given the petroleum-based nature of most plastic packaging materials. Oil price fluctuations directly impact production costs and profit margins, creating uncertainty in pricing strategies and long-term planning. Supply chain disruptions in global petrochemical markets can affect raw material availability and cost predictability, impacting overall market stability.

Regulatory compliance requirements, particularly in food contact applications and pharmaceutical packaging, create barriers to entry and increase operational costs for market participants. Stringent standards for food safety, migration testing, and quality certification require significant investment in testing facilities, quality control systems, and regulatory expertise that may limit participation by smaller manufacturers.

Technology adoption costs represent substantial barriers for companies seeking to implement advanced packaging technologies, including smart packaging, enhanced barrier properties, and sustainable material alternatives. Capital investment requirements for modern production equipment, quality control systems, and research and development capabilities may constrain market entry and expansion opportunities for some participants.

Sustainability innovation presents substantial opportunities for market participants who can develop and commercialize environmentally responsible packaging solutions. Circular economy initiatives and growing consumer demand for sustainable packaging create market potential for recyclable, biodegradable, and bio-based flexible packaging materials. Government support for environmental initiatives and sustainability programs provides additional incentives for companies investing in green packaging technologies.

Smart packaging integration offers significant growth opportunities through the incorporation of digital technologies, sensors, and interactive features that enhance consumer engagement and product functionality. Internet of Things (IoT) applications in packaging, including freshness indicators, temperature monitoring, and authentication features, create new value propositions and market differentiation opportunities.

Export market expansion leverages Saudi Arabia’s strategic geographic position and competitive manufacturing advantages to serve regional and international markets. Trade agreements and economic partnerships within the GCC and broader MENA region provide access to substantial export opportunities, particularly for specialized packaging solutions and high-quality products that meet international standards.

E-commerce packaging represents a rapidly expanding opportunity segment driven by the growth of online retail and direct-to-consumer distribution models. Specialized packaging requirements for e-commerce applications, including protective packaging, branded unboxing experiences, and return-friendly designs, create new market segments with premium pricing potential and growth prospects.

Supply chain evolution within the Saudi Arabia flexible plastic packaging market reflects broader trends toward localization, efficiency optimization, and resilience enhancement. Vertical integration strategies adopted by major players create competitive advantages through cost control, quality assurance, and supply security. The integration of petrochemical production with packaging manufacturing leverages Saudi Arabia’s natural resource advantages and creates sustainable competitive positioning.

Technological advancement drives continuous market evolution, with innovations in barrier properties, printing capabilities, and material science creating new application possibilities and performance improvements. Digital transformation initiatives encompass production optimization, quality control automation, and supply chain digitization that enhance operational efficiency and customer service capabilities.

Competitive intensity has increased as the market matures, driving focus on differentiation through innovation, quality, and service excellence. Market consolidation trends reflect strategic positioning for scale advantages, technology access, and market coverage expansion. Partnership strategies between international technology providers and local manufacturers facilitate knowledge transfer and capability development.

Regulatory landscape continues evolving with increasing emphasis on food safety, environmental protection, and consumer safety standards. Compliance requirements drive investment in quality systems, testing capabilities, and certification processes that enhance market credibility and access to premium applications. International standards adoption positions Saudi manufacturers for export market participation and global supply chain integration.

Comprehensive market analysis employs multiple research methodologies to ensure accuracy, reliability, and depth of insights into the Saudi Arabia flexible plastic packaging market. Primary research activities include structured interviews with industry executives, manufacturers, distributors, and end-users across various application segments. Survey methodologies capture quantitative data on market trends, purchasing patterns, and growth projections from representative samples of market participants.

Secondary research encompasses analysis of industry reports, government statistics, trade association data, and regulatory documentation to establish market context and validate primary research findings. Data triangulation techniques ensure consistency and reliability across multiple information sources, enhancing the credibility and accuracy of market assessments and projections.

Market modeling utilizes advanced analytical techniques including regression analysis, trend extrapolation, and scenario planning to develop robust market forecasts and identify key growth drivers. Segmentation analysis employs statistical clustering and classification methods to identify distinct market segments and their respective growth characteristics and competitive dynamics.

Expert validation processes involve consultation with industry specialists, technology experts, and market analysts to verify research findings and ensure practical relevance of insights and recommendations. Continuous monitoring systems track market developments, regulatory changes, and competitive activities to maintain current and accurate market intelligence throughout the research period.

Geographic distribution within Saudi Arabia reveals distinct regional characteristics that influence flexible plastic packaging market dynamics and growth patterns. Central Region dominance, anchored by Riyadh, represents the largest market concentration with approximately 42% of total consumption, driven by high population density, extensive retail infrastructure, and significant industrial activity including food processing and pharmaceutical manufacturing.

Eastern Province demonstrates strong market presence, accounting for roughly 28% of market share, supported by petrochemical industry concentration, port facilities, and industrial manufacturing clusters. The region’s strategic advantages include proximity to raw material sources, established industrial infrastructure, and access to export markets through major ports including Dammam and Jubail.

Western Region, centered on Jeddah and including the holy cities of Mecca and Medina, represents approximately 22% of market consumption, driven by diverse economic activities including tourism, trade, and consumer goods manufacturing. Religious tourism creates unique packaging requirements for food, beverages, and consumer products serving millions of annual visitors.

Northern and Southern regions collectively account for the remaining 8% of market share, with growth potential driven by ongoing development projects, agricultural expansion, and industrial diversification initiatives. Infrastructure development in these regions, including the NEOM project and southern border economic zones, creates future growth opportunities for flexible packaging applications.

Urban concentration patterns show that major metropolitan areas account for approximately 78% of total market consumption, reflecting population distribution, retail infrastructure development, and industrial activity concentration. Rural market development presents growth opportunities as infrastructure improvements and economic development initiatives expand market access and consumer purchasing power.

Market structure in the Saudi Arabia flexible plastic packaging sector features a dynamic competitive environment with both international and domestic players competing across various market segments. Leading companies have established strong market positions through strategic investments, technology advancement, and comprehensive product portfolios that serve diverse application requirements.

Competitive strategies emphasize differentiation through technology innovation, quality excellence, and customer service capabilities. Strategic partnerships between local manufacturers and international technology providers facilitate knowledge transfer, capability development, and market access expansion. Investment patterns reflect focus on capacity expansion, technology upgrading, and sustainability initiatives that position companies for long-term growth and market leadership.

Product segmentation within the Saudi Arabia flexible plastic packaging market encompasses diverse categories designed to serve specific application requirements and performance characteristics. Material-based segmentation includes polyethylene films and bags, polypropylene packaging, polyester films, and specialized barrier materials that provide enhanced protection and preservation properties.

By Material Type:

By Application Segment:

By End-Use Industry:

Food packaging applications dominate the Saudi Arabia flexible plastic packaging market, driven by expanding food processing capabilities, changing consumer preferences, and growing emphasis on food safety and preservation. Fresh food packaging represents the fastest-growing subsegment, with innovations in modified atmosphere packaging, antimicrobial films, and extended shelf-life technologies addressing consumer demands for convenience and quality.

Pharmaceutical packaging demonstrates exceptional growth potential, supported by Saudi Arabia’s healthcare sector expansion and increasing focus on local pharmaceutical manufacturing. Regulatory compliance requirements drive demand for specialized barrier films, tamper-evident packaging, and serialization-ready solutions that meet international pharmaceutical packaging standards.

Personal care packaging reflects growing consumer sophistication and brand consciousness, with emphasis on premium packaging solutions that enhance product appeal and user experience. Sustainability trends in this segment drive innovation in recyclable materials, refillable packaging systems, and reduced material usage without compromising functionality or aesthetics.

Industrial packaging applications serve diverse manufacturing sectors including chemicals, automotive, and construction materials, requiring specialized performance characteristics such as chemical resistance, temperature stability, and mechanical strength. Custom solutions development for industrial applications creates opportunities for premium pricing and long-term customer relationships.

E-commerce packaging emerges as a distinct category with unique requirements for product protection during shipping, brand presentation, and consumer convenience. Innovative designs for e-commerce applications include easy-open features, return-friendly packaging, and enhanced visual appeal that supports brand differentiation in the digital marketplace.

Manufacturers in the Saudi Arabia flexible plastic packaging market benefit from substantial competitive advantages including access to cost-effective raw materials, strategic geographic positioning, and government support for industrial development. Operational efficiency gains through proximity to petrochemical feedstocks reduce transportation costs and enhance supply chain reliability, creating sustainable competitive positioning in regional and international markets.

Brand owners and consumer goods companies gain access to sophisticated packaging solutions that enhance product differentiation, extend shelf life, and improve consumer convenience. Local sourcing capabilities provide supply chain security, reduced lead times, and enhanced responsiveness to market demands and seasonal fluctuations. Customization opportunities enable brand-specific packaging solutions that support marketing objectives and consumer engagement strategies.

Retailers and distributors benefit from improved product presentation, enhanced shelf life, and reduced handling costs through advanced flexible packaging solutions. Inventory optimization advantages include reduced storage space requirements, improved product protection, and enhanced supply chain efficiency that supports profitability and customer satisfaction objectives.

Consumers experience enhanced convenience, product quality, and value through advanced flexible packaging technologies. Lifestyle benefits include portion control, resealable packaging, and on-the-go consumption formats that align with modern lifestyle preferences and time constraints. Product safety improvements through advanced barrier properties and tamper-evident features enhance consumer confidence and satisfaction.

Environmental stakeholders benefit from ongoing innovation in sustainable packaging solutions, including recyclable materials, reduced material usage, and circular economy initiatives. Waste reduction potential through optimized packaging design and material efficiency contributes to environmental protection objectives while maintaining product functionality and consumer satisfaction.

Strengths:

Weaknesses:

Opportunities:

Threats:

Sustainability transformation represents the most significant trend shaping the Saudi Arabia flexible plastic packaging market, with increasing emphasis on circular economy principles, recyclable materials, and reduced environmental impact. Bio-based materials development and adoption accelerate as companies respond to consumer preferences and regulatory pressures for environmentally responsible packaging solutions.

Smart packaging integration gains momentum through incorporation of digital technologies, sensors, and interactive features that enhance consumer engagement and product functionality. Internet of Things (IoT) applications include freshness monitoring, authentication features, and supply chain tracking capabilities that create new value propositions and market differentiation opportunities.

Customization and personalization trends drive demand for flexible packaging solutions that can accommodate small batch production, variable data printing, and brand-specific design requirements. Digital printing technologies enable cost-effective customization and rapid response to market demands and seasonal variations.

E-commerce optimization influences packaging design priorities, with growing emphasis on protective properties, unboxing experience, and return-friendly features that support online retail growth. Omnichannel packaging solutions address the need for packaging that performs effectively across multiple distribution channels and consumer touchpoints.

Barrier enhancement technologies continue advancing to address evolving product preservation requirements, particularly in food and pharmaceutical applications. Nanotechnology applications and advanced coating systems provide superior barrier properties while maintaining packaging flexibility and cost-effectiveness.

Manufacturing capacity expansion initiatives across the Saudi Arabia flexible plastic packaging market reflect strong confidence in long-term growth prospects and market opportunities. Major investments in production facilities, technology upgrades, and quality enhancement systems position market participants for sustained growth and competitive advantage in domestic and export markets.

Technology partnerships between local manufacturers and international technology providers facilitate knowledge transfer, capability development, and innovation acceleration. Joint ventures and licensing agreements enable access to advanced packaging technologies, specialized materials, and global best practices that enhance market competitiveness and product quality.

Sustainability initiatives gain prominence as companies invest in recyclable materials development, waste reduction programs, and circular economy solutions. MarkWide Research analysis indicates that sustainability-focused investments account for approximately 15% of total capital expenditure in the sector, reflecting growing commitment to environmental responsibility and market positioning.

Regulatory compliance enhancement drives investment in quality systems, testing capabilities, and certification processes that ensure adherence to international standards and market access requirements. Food safety certifications, pharmaceutical compliance systems, and environmental management standards become increasingly important for market participation and customer acceptance.

Digital transformation initiatives encompass production optimization, supply chain digitization, and customer service enhancement through technology integration. Industry 4.0 concepts including automation, data analytics, and predictive maintenance improve operational efficiency and quality consistency while reducing production costs and environmental impact.

Strategic positioning recommendations for market participants emphasize the importance of balancing growth opportunities with sustainability requirements and technological advancement needs. Investment priorities should focus on developing capabilities in sustainable packaging solutions, smart packaging technologies, and export market development that leverage Saudi Arabia’s competitive advantages while addressing evolving market demands.

Innovation focus areas should prioritize development of environmentally responsible packaging solutions, including recyclable materials, biodegradable options, and circular economy applications that address growing consumer and regulatory pressures. Research and development investments in barrier enhancement technologies, smart packaging integration, and customization capabilities create competitive differentiation opportunities and premium market positioning.

Market expansion strategies should emphasize export market development, particularly within the GCC region and broader MENA markets where Saudi manufacturers can leverage cost advantages and strategic positioning. Partnership development with international brands and distributors facilitates market access and capability enhancement while reducing market entry risks and investment requirements.

Operational excellence initiatives should focus on quality enhancement, cost optimization, and supply chain efficiency improvement that support competitive positioning and profitability objectives. Digital transformation investments in production automation, quality control systems, and customer service capabilities enhance operational efficiency and market responsiveness.

Regulatory compliance preparation should anticipate evolving environmental regulations, food safety requirements, and international standards that may impact market access and operational requirements. Proactive compliance strategies reduce regulatory risks and position companies for market leadership in quality and safety standards.

Long-term growth prospects for the Saudi Arabia flexible plastic packaging market remain highly favorable, supported by fundamental demographic trends, economic diversification initiatives, and expanding industrial capabilities. Market evolution toward more sophisticated packaging solutions, sustainability integration, and technology advancement creates opportunities for value creation and competitive differentiation throughout the forecast period.

Technology advancement will continue driving market evolution, with particular emphasis on smart packaging integration, barrier enhancement technologies, and sustainable material development. Innovation cycles are expected to accelerate as companies invest in research and development capabilities and establish partnerships with technology providers and research institutions.

Export market development represents significant growth potential, with MWR projections indicating that export revenues could account for 35% of total market value by the end of the forecast period. Regional market integration and international trade expansion create opportunities for Saudi manufacturers to leverage competitive advantages and establish global market presence.

Sustainability transformation will reshape market dynamics, with increasing emphasis on circular economy principles, recyclable materials, and environmental responsibility. Regulatory evolution toward stricter environmental standards and consumer preference shifts toward sustainable packaging create both challenges and opportunities for market participants.

Market consolidation trends may accelerate as companies seek scale advantages, technology access, and market coverage expansion through strategic partnerships, acquisitions, and joint ventures. Competitive positioning will increasingly depend on innovation capabilities, sustainability credentials, and operational excellence rather than traditional cost-based competition.

The Saudi Arabia flexible plastic packaging market stands at a pivotal juncture, characterized by robust growth prospects, evolving consumer demands, and transformative technological advancement. Market fundamentals remain strong, supported by demographic trends, economic diversification initiatives, and expanding industrial capabilities that create sustained demand for sophisticated packaging solutions across multiple application segments.

Strategic opportunities abound for market participants who can successfully navigate the balance between growth acceleration and sustainability requirements while leveraging Saudi Arabia’s competitive advantages in raw material access, strategic positioning, and government support. Innovation leadership in sustainable packaging solutions, smart packaging technologies, and export market development will determine long-term success and market positioning.

Future success in the Saudi Arabia flexible plastic packaging market will require comprehensive strategies that encompass technology advancement, sustainability integration, operational excellence, and market expansion initiatives. Companies that can effectively combine these elements while maintaining focus on quality, customer service, and regulatory compliance will be best positioned to capitalize on the substantial growth opportunities that lie ahead in this dynamic and evolving market landscape.

What is Flexible Plastic Packaging?

Flexible Plastic Packaging refers to packaging made from flexible materials that can be easily shaped and molded. It is widely used in various applications such as food packaging, personal care products, and medical supplies.

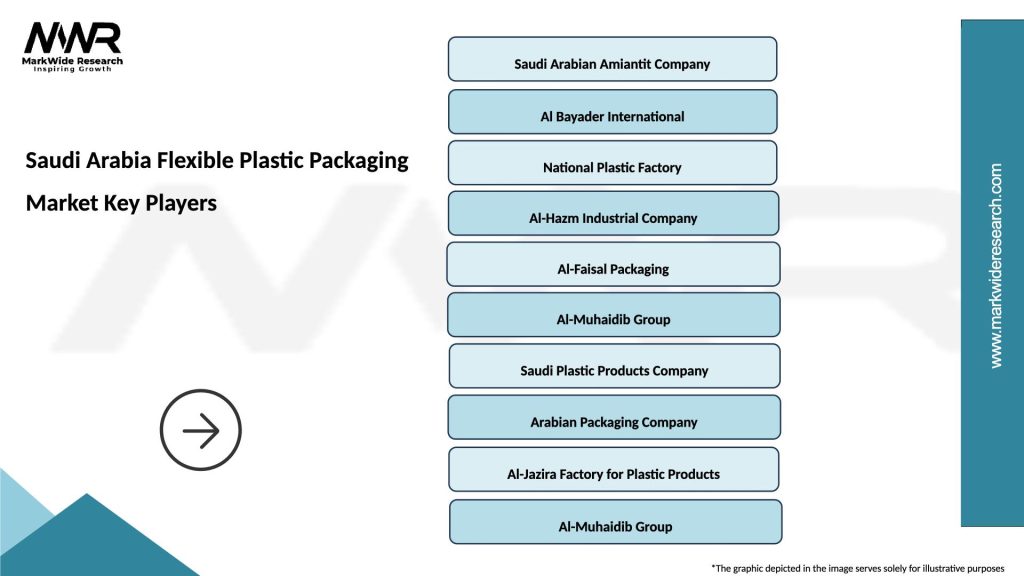

What are the key players in the Saudi Arabia Flexible Plastic Packaging Market?

Key players in the Saudi Arabia Flexible Plastic Packaging Market include companies like Al Bayader International, National Plastic Factory, and Saudi Plastic Products Company, among others.

What are the growth factors driving the Saudi Arabia Flexible Plastic Packaging Market?

The growth of the Saudi Arabia Flexible Plastic Packaging Market is driven by increasing demand for convenient packaging solutions, the rise in e-commerce, and a growing focus on sustainable packaging options.

What challenges does the Saudi Arabia Flexible Plastic Packaging Market face?

Challenges in the Saudi Arabia Flexible Plastic Packaging Market include regulatory pressures regarding plastic waste, competition from alternative packaging materials, and fluctuating raw material prices.

What opportunities exist in the Saudi Arabia Flexible Plastic Packaging Market?

Opportunities in the Saudi Arabia Flexible Plastic Packaging Market include the development of biodegradable packaging solutions, innovations in packaging technology, and expanding applications in the food and beverage sector.

What trends are shaping the Saudi Arabia Flexible Plastic Packaging Market?

Trends in the Saudi Arabia Flexible Plastic Packaging Market include a shift towards eco-friendly materials, increased automation in packaging processes, and the growing popularity of stand-up pouches and resealable packaging.

Saudi Arabia Flexible Plastic Packaging Market

| Segmentation Details | Description |

|---|---|

| Product Type | Stand-Up Pouches, Shrink Films, Rigid Containers, Flexible Bags |

| Material | Polyethylene, Polypropylene, Polyvinyl Chloride, Bioplastics |

| End User | Food & Beverage, Personal Care, Pharmaceuticals, Household Products |

| Packaging Type | Flexible Packaging, Rigid Packaging, Vacuum Packaging, Barrier Packaging |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the Saudi Arabia Flexible Plastic Packaging Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at