444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The metal coil lamination market is witnessing significant growth globally due to the increasing demand for laminated metal coils in various industries. Metal coil lamination involves the process of applying a protective film or coating on metal coils to enhance their durability, aesthetics, and resistance to corrosion. This market overview will provide insights into the meaning of metal coil lamination, key market insights, market drivers, market restraints, market opportunities, market dynamics, regional analysis, competitive landscape, segmentation, category-wise insights, key benefits for industry participants and stakeholders, SWOT analysis, market key trends, the impact of Covid-19, key industry developments, analyst suggestions, future outlook, and a concluding remark.

Meaning

Metal coil lamination refers to the process of applying a protective film or coating on metal coils. This protective layer acts as a barrier against corrosion, abrasion, and other forms of damage. It not only enhances the durability and longevity of metal coils but also provides an attractive finish, making them suitable for various applications across industries.

Executive Summary

The metal coil lamination market is experiencing substantial growth, driven by the rising demand for laminated metal coils in industries such as automotive, construction, appliances, and packaging. The market is characterized by increasing investments in research and development activities to develop advanced laminating technologies and eco-friendly lamination materials. Key market players are focusing on strategic collaborations and partnerships to expand their product offerings and strengthen their market presence.

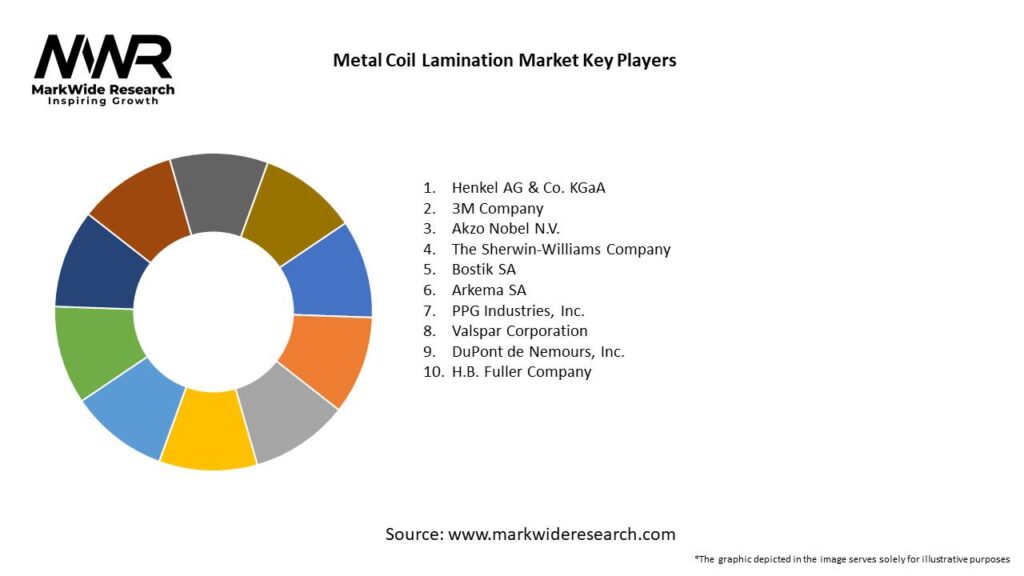

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

The metal coil lamination market is propelled by several key drivers:

Market Restraints

While the metal coil lamination market is witnessing growth, certain factors act as restraints:

Market Opportunities

The metal coil lamination market offers several opportunities for growth and expansion:

Market Dynamics

The metal coil lamination market is driven by various dynamics, including market trends, customer preferences, technological advancements, and regulatory landscape. Understanding these dynamics is crucial for market players to stay competitive and capitalize on the emerging opportunities.

Regional Analysis

The metal coil lamination market is analyzed across various regions, including North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa. Each region exhibits unique market characteristics influenced by factors such as industrial development, economic growth, and market demand. A comprehensive regional analysis helps in identifying potential growth markets and tailoring strategies accordingly.

Competitive Landscape

Leading Companies in Metal Coil Lamination Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

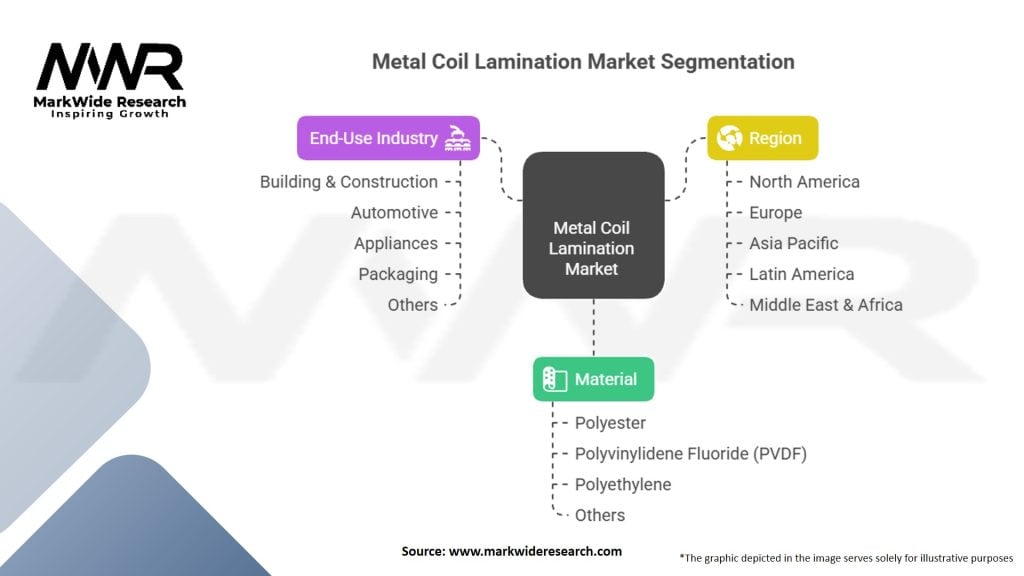

Segmentation

The metal coil lamination market can be segmented based on various factors such as material type, end-use industry, and geography. Segmentation helps in understanding specific market segments, their growth potential, and the target customer base.

Category-wise Insights

The metal coil lamination market can be categorized based on the type of laminating materials used, such as polyvinyl chloride (PVC), polyethylene terephthalate (PET), polypropylene (PP), and others. Each category offers unique characteristics and benefits, catering to specific industry requirements.

Key Benefits for Industry Participants and Stakeholders

Industry participants and stakeholders in the metal coil lamination market can benefit in several ways:

SWOT Analysis

Strengths:

Transformer Efficiency: Laminated cores reduce eddy‑current losses in electrical equipment.

Customization: Available in various grades and thicknesses to suit voltage and frequency needs.

Proven Technology: Decades of use in power and distribution transformers worldwide.

Weaknesses:

Manufacturing Precision: Requires tight tolerances, raising scrap rates if not well controlled.

Capital‑Intensive: High cost of specialized stamping and coating equipment.

Lead Times: Custom grades can face lengthy production ramps.

Opportunities:

Grid Modernization: Infrastructure upgrades and smart grid rollouts drive transformer replacements.

Renewable Integration: Wind and solar farms require specialized laminations for inverters and transformers.

Advanced Coatings: Nano‑coatings promise further efficiency gains.

Threats:

Alternative Core Designs: Amorphous metal and powder‑core technologies challenge grain‑oriented steel.

Raw Material Costs: Specialty steel price fluctuations impact overall product cost.

Import Competition: Low‑cost laminations from Asia may undercut local producers.

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic has had a significant impact on the metal coil lamination market. The global economic slowdown, supply chain disruptions, and temporary shutdown of industries have affected market growth. However, the market has shown resilience and is expected to recover gradually as economies reopen and industries resume operations.

Key Industry Developments

Analyst Suggestions

Future Outlook

The metal coil lamination market is poised for steady growth in the coming years. The increasing demand for durable and aesthetically appealing laminated metal coils across industries, coupled with advancements in lamination technologies, will drive market expansion. Emerging economies and the growing focus on sustainable solutions present significant growth opportunities for market players.

Conclusion

The metal coil lamination market is witnessing robust growth driven by the increasing demand for laminated metal coils in automotive, construction, packaging, and other industries. While market drivers such as the automotive industry’s demand for attractive and durable surfaces and the growing construction sector propel market growth, factors like high capital investment and environmental concerns act as restraints. However, emerging opportunities in emerging economies and technological advancements in lamination processes and materials provide a positive outlook for the market’s future. Strategic collaborations, product diversification, and sustainable initiatives are key strategies for industry participants to capitalize on these opportunities and thrive in the competitive landscape of the metal coil lamination market.

Metal Coil Lamination Market

| Segmentation Details | Description |

|---|---|

| Material | Polyester, Polyvinylidene Fluoride (PVDF), Polyethylene, Others |

| End-Use Industry | Building & Construction, Automotive, Appliances, Packaging, Others |

| Region | North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in Metal Coil Lamination Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at