Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

-

Barrier Packaging Trend: Rising demand for moisture and oxygen barrier packaging in foods, pharmaceuticals, and electronics is a primary driver for tie layer resin consumption.

-

Sustainability Shift: Regulatory bans on multilayer non‑recyclable plastics are pushing development of mono‑material recyclable solutions using tie layers to bond layers of the same base polymer (e.g., PP/PP).

-

E‑Commerce Boom: The growth of online retail is fueling demand for protective flexible packaging and mailers that rely on multilayer films with tie layers for puncture and tear resistance.

-

Bio‑Based and Recycled Grades: Innovation in bio‑PE tie resins and compatibility with post‑consumer recycled (PCR) content addresses circular economy targets.

-

Industry Consolidation: Strategic M&A and partnerships between resin producers and packaging converters accelerate technology transfer and market penetration.

Market Drivers

-

Growing Flexible Packaging Demand: Global consumption of flexible films in food and non‑food packaging sectors is increasing, requiring advanced multilayer structures and tie layers.

-

Sustainability and Recycling Regulations: Government mandates (e.g., EU’s Packaging and Packaging Waste Regulation) stimulate adoption of recyclable, mono‑material multilayer films reliant on tie layer resins.

-

E‑Commerce Packaging Needs: Rising online retail volumes necessitate durable, protective flexible packaging solutions with high tear and puncture resistance.

-

Advancements in Polymer Chemistry: Development of functionalized polyolefins, metallocene‑based tie resins, and bio‑based chemistries enhances performance and sustainability.

-

Healthcare and Medical Packaging: Stringent sterility and barrier requirements in pharmaceutical packaging strengthen demand for specialized tie layer resins.

-

Lightweighting Initiatives: Automotive and construction sectors leverage multilayer composites with tie layers to reduce weight while maintaining structural integrity.

Market Restraints

-

Feedstock Price Volatility: Fluctuating crude oil and monomer prices impact raw material costs, affecting resin pricing and profit margins.

-

Technical Complexity: Formulating tie layers for optimal adhesion across diverse polymer combinations requires extensive R&D and process expertise.

-

Regulatory Hurdles: Evolving global regulations on chemicals and microplastics pose compliance challenges and may limit certain chemistries.

-

Competition from Alternative Technologies: Barrier coatings, lamination adhesives, and emerging metallized or nano‑coated films offer alternative bonding solutions.

-

Limited Recycling Infrastructure: Inadequate recycling systems in some regions hamper the adoption of recyclable multilayer films.

Market Opportunities

-

Mono‑Material Multilayer Films: Development of PP/PP or PE/PE multilayer structures using tie layers to enable fully recyclable films.

-

Bio‑Based Tie Resins: Commercialization of certified bio‑PE and bio‑PP tie layers sourced from renewable feedstocks.

-

Functional Coatings Integration: Hybrid solutions combining hydrophilic or antimicrobial coatings with tie layers for active packaging.

-

Advanced Medical Applications: Biocompatible and sterilizable tie layer resins for medical device packaging and drug delivery systems.

-

Emerging Economies: Rapid industrial growth in Asia‑Pacific and Latin America offers expansion potential for packaging and automotive applications.

Market Dynamics

-

Supply Side: Technology licensing, capacity expansions, vertical integration by major resin producers, and collaboration with catalyst suppliers drive supply growth.

-

Demand Side: Converters and brand owners demand high‑performance, cost‑effective, and sustainable tie layer solutions, influencing product development and customization.

-

Economic and Policy Influences: Fluctuating currency rates, trade policies, and environmental regulations (e.g., Extended Producer Responsibility) shape regional dynamics.

Regional Analysis

-

North America: Mature packaging market with strong demand for recyclable films and advanced medical packaging; leading resin producers allocate R&D to high‑performance tie layers.

-

Europe: Stringent sustainability mandates drive rapid adoption of recyclable multilayer packaging using tie layers; bio‑based resin innovations flourish.

-

Asia‑Pacific: Highest growth region, led by China and India; expanding food & beverage and e‑tail sectors fuel demand; infrastructure investments improve recycling.

-

Latin America: Steady growth in FMCG packaging and automotive sectors; increasing adoption of modern flexible packaging and multilayer films.

-

Middle East & Africa: Emerging demand in foodservice and healthcare, but limited recycling infrastructure; growth tied to industrialization and petrochemical feedstock availability.

Competitive Landscape

Leading Companies in Tie Layer Resin Market

- Dow Chemical Company

- LyondellBasell Industries N.V.

- DuPont de Nemours, Inc.

- Exxon Mobil Corporation

- Solvay SA

- Borealis AG

- Mitsui Chemicals, Inc.

- Lotte Chemical Corporation

- Chevron Phillips Chemical Company LLC

- INEOS Group Holdings S.A.

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

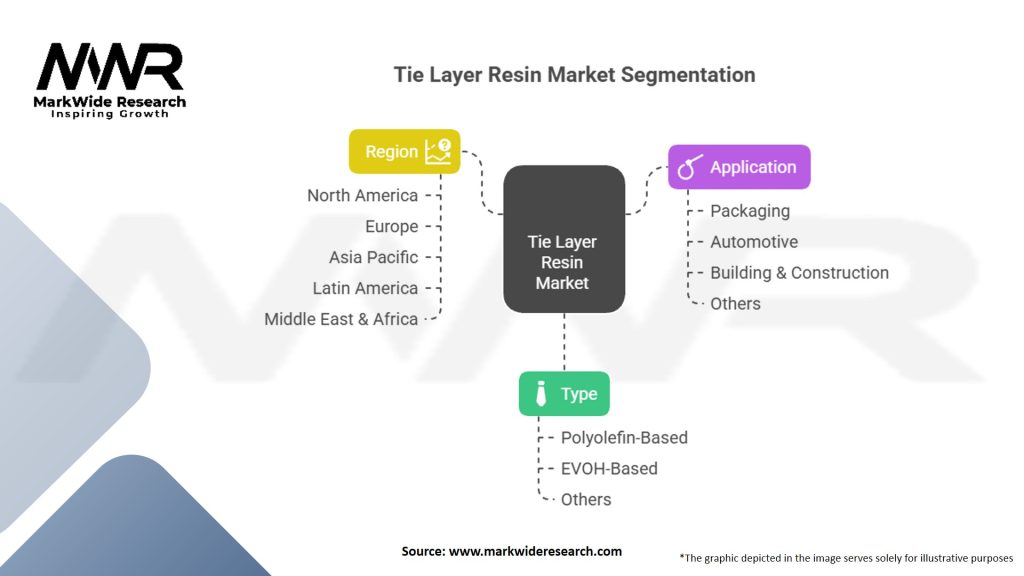

Segmentation

-

By Resin Type:

-

Linear Low Density Polyethylene (LLDPE)

-

Low Density Polyethylene (LDPE)

-

High Density Polyethylene (HDPE)

-

Polypropylene (PP)

-

Ethylene‑Vinyl Acetate (EVA)

-

Others (EMA, EEA)

-

-

By Application:

-

Food & Beverage Packaging

-

Pharmaceutical & Medical Packaging

-

Consumer Goods Packaging

-

Automotive Components

-

Industrial & Construction Films

-

Agriculture Films

-

-

By Processing Technology:

-

Blown Film Co‑Extrusion

-

Cast Film Co‑Extrusion

-

Extrusion Lamination

-

Others (Injection Molding, Sheet Extrusion)

-

-

By End‑User:

-

Packaging Converters

-

OEMs (Automotive, Construction)

-

Healthcare Device Manufacturers

-

-

By Region:

-

North America

-

Europe

-

Asia‑Pacific

-

Latin America

-

Middle East & Africa

-

Category-wise Insights

-

LLDPE Tie Layers: Offer high toughness and flexibility, widely used in flexible food packaging and heavy‑duty industrial films.

-

LLDPE Bio‑Based Grades: Emerging segment combining performance with sustainability credentials.

-

PP Tie Layers: Preferred for high‑temperature applications and rigid packaging/containers co‑molded with barrier layers.

-

EVA/EVA Copolymers: Provide excellent adhesion to polar substrates, used in high‑barrier and specialty films.

Key Benefits for Industry Participants and Stakeholders

-

Enhanced Product Performance: Tie layers enable multilayer films with superior barrier, mechanical, and seal properties.

-

Sustainability Gains: Facilitate recyclable mono‑material structures, reducing plastic waste and supporting circular economy goals.

-

Cost Optimization: Optimize material use by enabling thinner layers of expensive barrier polymers bonded to cheaper polyolefins.

-

Innovation Acceleration: Close collaboration between resin producers and converters drives rapid prototyping and technology adoption.

-

Market Differentiation: Advanced tie layer technologies allow brand owners to offer premium, sustainable packaging solutions.

SWOT Analysis

Strengths:

-

Critical enabling material for advanced multilayer structures

-

Broad application across packaging and industrial sectors

-

Ongoing polymer innovations and wide product portfolio

Weaknesses:

-

High dependence on petrochemical feedstocks (subject to price volatility)

-

Complex formulation and processing requirements

-

Limited recycling infrastructure in certain regions

Opportunities:

-

Bio‑based and recycled resin integration

-

Expansion in emerging markets with growing packaging demand

-

Development of smart, stimuli‑responsive tie layers

Threats:

-

Stricter regulations on virgin plastics and microplastics

-

Competition from alternative barrier technologies (coatings, metallization)

-

Consolidation among converters and brand owners may squeeze resin margins

Market Key Trends

-

Mono‑Material Multilayer Films: Growth in PP/PP and PE/PE mono‑material structures using tie layers to enable full recyclability.

-

Bio‑PE and Recycled Content: Increasing commercial availability of certified bio‑PE tie resins and PCR‑compatible grades.

-

Metallocene vs Ziegler‑Natta: Shift towards metallocene‑catalyzed tie layers for superior clarity, sealability, and processability.

-

Smart Packaging Integration: Tie layers in films with embedded sensors, antimicrobial agents, or active packaging functions.

-

Digitalization and Industry 4.0: Use of process analytical technology (PAT) in compounding and extrusion to ensure consistent tie layer quality.

Covid-19 Impact

-

Supply Chain Disruptions: Initial resin shortages and logistics challenges caused converter downtime and backlog; subsequently mitigated by increased local capacities.

-

Surge in Protective Packaging: Demand spike for medical PPE, sterilizable films, and barrier packaging for pharmaceuticals increased tie layer resin consumption.

-

E‑Commerce Boom: Lockdowns accelerated growth in e‑tail packaging, boosting demand for durable flexible films with tie layers.

-

Cost Pressures: Margin squeeze due to feedstock price spikes and converter financial constraints; leveraged scale‑up to optimize costs.

Key Industry Developments

-

Capacity Expansions: Dow’s new tie layer resin line in Texas; Borealis’ debottlenecking in Europe.

-

Sustainability Partnerships: ExxonMobil and Eastman collaborations on recyclable film solutions.

-

Product Launches: LyondellBasell’s metallocene‑based tie layers with lower seal initiation temperature; AkzoNobel’s functionalized EVA grades.

-

R&D Consortia: Packaging industry consortiums in Europe focusing on mono‑material film recyclability.

-

Acquisitions: Strategic M&A to consolidate tie resin compounding capabilities and regional distribution.

Analyst Suggestions

-

Invest in Sustainable Chemistries: Prioritize development of bio‑based, recycled‑content tie layers to meet regulatory and brand sustainability targets.

-

Optimize Supply Chains: Diversify feedstock sources and expand compounding sites near converter clusters to reduce logistics risks.

-

Collaborate Upstream: Partner with packaging converters early in development to co-create tie layer solutions for specific multilayer applications.

-

Leverage Digital Tools: Implement real‑time monitoring, predictive maintenance, and PAT in compounding and extrusion to ensure consistent product quality.

-

Expand in Emerging Economies: Target Asia‑Pacific and Latin American markets with cost‑effective grades suited to local needs and recycling infrastructure.

-

Focus on High‑Value Segments: Prioritize medical, pharmaceutical, and e‑commerce packaging sectors where performance requirements justify premium tie layer solutions.

Future Outlook

The global tie layer resin market is expected to sustain a healthy CAGR of 5–7% through 2030. Key growth enablers include continued packaging lightweighting, regulatory push toward recyclability, and ongoing advancements in functionalized polymer chemistries. Collaboration across the value chain—from catalyst suppliers and resin producers to converters and brand owners—will accelerate the commercialization of mono‑material, stimuli‑responsive, and bio‑based tie layer solutions. Regions with robust recycling ecosystems (e.g., Europe) and rapidly expanding packaging sectors (Asia‑Pacific) will be hotspots for investment. As sustainability, performance, and cost‑efficiency converge, tie layer resins will remain indispensable in the manufacturing of next‑generation multilayer films and composites.

Conclusion

Tie layer resins occupy a strategic position in the global multi‑layer polymer market, enabling performance attributes—barrier resistance, mechanical strength, sealability, and recyclability—that single polymers cannot achieve alone. Growth prospects are driven by packaging innovations, sustainability imperatives, and the demand for advanced healthcare and industrial materials. While challenges such as feedstock volatility, regulatory pressures, and technical complexity persist, proactive investments in R&D, sustainable chemistries, and digital manufacturing will secure tie layer resins’ role as critical enablers of high‑performance, eco‑efficient packaging and composite solutions. Stakeholders who embrace collaboration, sustainability, and technological leadership will thrive in this dynamic market, shaping the future of packaging and materials engineering.