444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The concrete formwork market plays a crucial role in the construction industry, providing a temporary structure to support the concrete until it cures and gains sufficient strength to support itself. It is an essential component of construction projects, enabling the creation of various structures such as buildings, bridges, dams, and tunnels. Concrete formwork serves as a mold or framework, shaping the concrete into the desired form and ensuring structural integrity.

Meaning

Concrete formwork refers to the process of creating temporary structures or molds to hold and shape concrete during construction. These structures are typically made of wood, steel, aluminum, or other materials, and they provide support and containment for the fresh concrete until it hardens and gains enough strength to withstand loads. The formwork system used can vary depending on the complexity of the structure and the specific requirements of the project.

Executive Summary

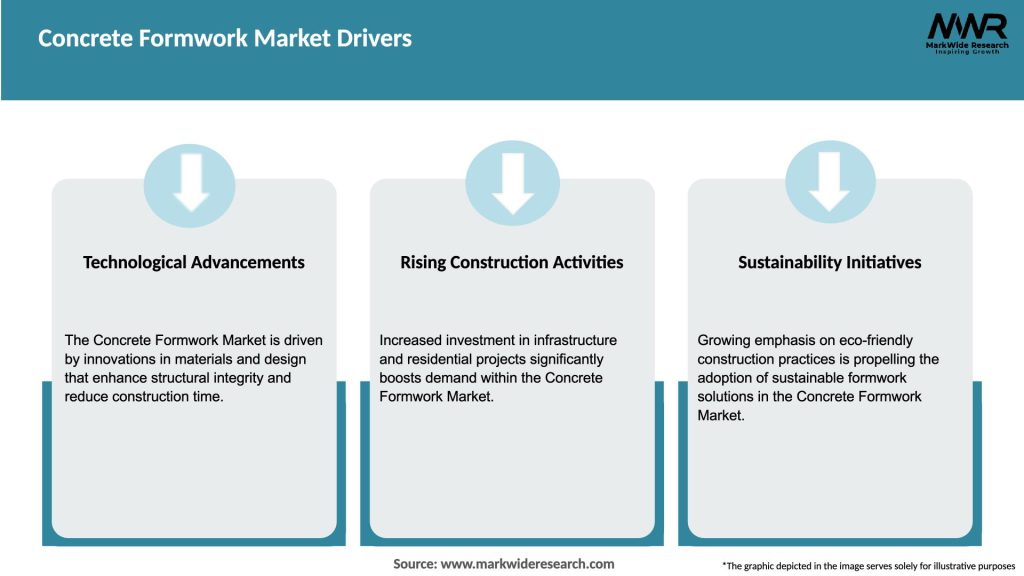

The global concrete formwork market has witnessed significant growth in recent years, driven by the booming construction industry worldwide. The demand for new infrastructure and the need to renovate existing structures have fueled the market’s expansion. Technological advancements in formwork systems, such as the introduction of modular and reusable formwork, have also contributed to market growth. Additionally, the focus on sustainable construction practices and the adoption of eco-friendly formwork solutions have created opportunities for market players.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The concrete formwork market is influenced by various dynamics, including economic factors, technological advancements, regulatory policies, and industry trends. Understanding these dynamics is crucial for market players to identify opportunities, address challenges, and adapt to changing market conditions.

Economic factors, such as GDP growth, infrastructure investments, and urbanization rates, play a significant role in shaping the demand for concrete formwork. Emerging economies with rapid urbanization and substantial infrastructure development provide a fertile ground for market expansion. Additionally, government policies, such as affordable housing initiatives and infrastructure development programs, can significantly impact the market’s growth trajectory.

Technological advancements in formwork systems have transformed the construction industry. The introduction of modular and reusable formwork has improved construction efficiency, reduced labor costs, and enhanced project timelines. The integration of digital tools and BIM in formwork planning and design has also streamlined construction processes. Continuous innovation and R&D efforts in formwork technology will drive market growth.

Regulatory policies and environmental concerns are driving the adoption of sustainable construction practices. The demand for eco-friendly formwork materials and practices is increasing, creating opportunities for market players who can provide environmentally friendly solutions. Green building certifications and government initiatives focused on sustainability are influencing the choice of formwork materials and systems.

The construction industry’s labor shortage and the need for skilled workers are challenges faced by the concrete formwork market. The availability of skilled labor for formwork installation and dismantling can impact project timelines and overall construction efficiency. Market players need to invest in training programs and technology solutions that can reduce the dependency on skilled labor.

The COVID-19 pandemic has had a significant impact on the construction industry and, consequently, the concrete formwork market. The temporary suspension of construction activities and supply chain disruptions have affected project timelines and investments. However, as economies recover and construction activities resume, the demand for concrete formwork is expected to rebound.

Regional Analysis

The concrete formwork market exhibits regional variations based on factors such as economic growth, infrastructure development, construction activities, and government policies. The analysis of regional markets provides insights into the specific dynamics and growth prospects for each region.

Competitive Landscape

Leading Companies in the Concrete Formwork Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The concrete formwork market can be segmented based on various factors, including material type, formwork type, and end-use industry. Understanding the market segmentation provides insights into the specific market dynamics and opportunities within each segment.

The material type segment depends on factors such as cost, strength, durability, and ease of use. Wood is commonly used for small-scale projects, while steel and aluminum are preferred for larger and complex structures.

The formwork type segment categorizes the different formwork systems based on their design, construction method, and usability. Traditional formwork involves on-site construction of formwork using timber, while engineered formwork includes prefabricated systems designed for specific project requirements. Reusable formwork allows for multiple use cycles, reducing material waste and costs.

The end-use industry segment identifies the specific sectors that utilize concrete formwork in construction projects. Residential construction includes housing developments and individual homes, while commercial construction encompasses office buildings, retail spaces, and hotels. Infrastructure construction involves the development of roads, bridges, airports, and other public facilities. Industrial construction includes factories, warehouses, and manufacturing plants.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The COVID-19 pandemic had a significant impact on the construction industry, including the concrete formwork market. The temporary suspension of construction activities, supply chain disruptions, and labor shortages affected the market’s growth during the pandemic. Construction projects were delayed or put on hold, leading to a decline in formwork demand.

However, as economies gradually recover and construction activities resume, the concrete formwork market is expected to rebound. Government stimulus packages and infrastructure development initiatives can provide opportunities for market recovery. The need for affordable housing, healthcare facilities, and improved infrastructure will continue to drive the demand for concrete formwork in the post-pandemic period.

Key Industry Developments

Analyst Suggestions

Future Outlook

The future of the concrete formwork market looks promising, driven by ongoing infrastructure development, urbanization, and the adoption of sustainable construction practices. Technological advancements, such as 3D printing, digitalization, and modular formwork systems, will continue to shape the market.

The demand for eco-friendly and reusable formwork materials and systems will increase as sustainability becomes a key consideration in construction projects. The integration of digital tools and BIM will streamline formwork processes and improve project efficiency. Safety standards and worker well-being will remain a top priority for the industry.

Overall, the concrete formwork market is expected to grow steadily, with opportunities for market players who can provide innovative, sustainable, and efficient formwork solutions.

Conclusion

The concrete formwork market plays a vital role in the construction industry, providing structural support and shape to concrete structures. The market is driven by factors such as infrastructure development, urbanization, and the demand for sustainable construction practices.

Key market insights indicate the diverse material options, formwork types, and end-use industries within the market. Wood, steel, and aluminum are commonly used materials, while traditional, engineered, and reusable formwork systems cater to different project requirements. Residential, commercial, infrastructure, and industrial construction sectors are the primary end users of concrete formwork.

The market’s competitive landscape is influenced by product quality, price, brand reputation, and customer relationships. Companies are investing in R&D, forming partnerships, and expanding their market presence to gain a competitive edge.

The future outlook of the concrete formwork market is promising, driven by ongoing infrastructure development, technological advancements, and the focus on sustainability. Embracing digitalization, ensuring safety compliance, and investing in innovative solutions will be key to success in the evolving market.

What is concrete formwork?

Concrete formwork refers to the temporary or permanent molds used to shape and support concrete until it hardens. It is essential in construction for creating structures like walls, slabs, and columns.

Who are the key players in the concrete formwork market?

Key players in the concrete formwork market include PERI Group, Doka GmbH, Altrad Group, and BrandSafway, among others.

What are the main drivers of growth in the concrete formwork market?

The main drivers of growth in the concrete formwork market include the increasing demand for residential and commercial construction, advancements in formwork technology, and the rising focus on sustainable building practices.

What challenges does the concrete formwork market face?

Challenges in the concrete formwork market include the high initial costs of formwork systems, the need for skilled labor, and potential delays in construction schedules due to weather conditions.

What opportunities exist in the concrete formwork market?

Opportunities in the concrete formwork market include the growing trend of modular construction, the expansion of infrastructure projects, and the increasing adoption of advanced materials and technologies.

What trends are shaping the concrete formwork market?

Trends shaping the concrete formwork market include the rise of digital technologies for formwork design, the use of eco-friendly materials, and the integration of automation in construction processes.

Concrete Formwork Market

| Segmentation Details | Description |

|---|---|

| Type | Timber Formwork, Steel Formwork, Aluminum Formwork, Others |

| Application | Residential, Commercial, Industrial, Others |

| Region | North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Concrete Formwork Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at