444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The industrial coal burner sales market involves the production, distribution, and sales of burners specifically designed to combust coal for industrial applications. These burners are used in various industries such as power generation, steel production, cement manufacturing, and chemical processing to generate heat and energy from coal.

Meaning

Industrial coal burners are combustion devices designed to efficiently burn coal in industrial processes. These burners are engineered to ensure complete combustion, reduce emissions, and optimize fuel efficiency. They are a critical component in industries that rely on coal as a primary energy source.

Executive Summary

The industrial coal burner sales market is influenced by factors such as the demand for energy, industrial growth, and advancements in burner technology. Despite the global shift towards cleaner energy sources, coal remains a significant fuel source for many industries, particularly in regions where it is abundant and economically viable. The market is characterized by technological innovations aimed at improving efficiency and reducing environmental impact.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The market dynamics of the industrial coal burner sales market are shaped by the interplay of technological advancements, regulatory frameworks, and market demand. While there is a push towards cleaner energy, coal burners continue to play a significant role in many industrial processes, especially in regions with abundant coal reserves.

Regional Analysis

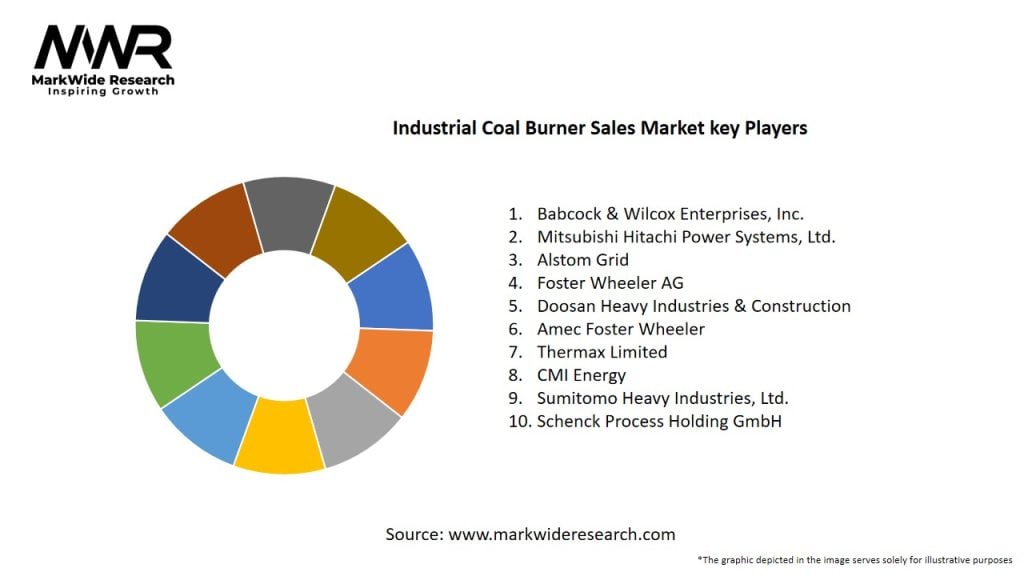

Competitive Landscape

Segmentation

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Strengths: High efficiency, cost-effectiveness, technological advancements in emission control.

Weaknesses: Environmental impact, regulatory challenges, and competition from cleaner energy sources.

Opportunities: Retrofits, emerging markets, technological innovations in emission reduction.

Threats: Stringent environmental regulations, market volatility, and declining public perception of coal.

Market Key Trends

Covid-19 Impact

Key Industry Developments

Analyst Suggestions

Future Outlook

The future outlook for the industrial coal burner sales market is shaped by a balance between the ongoing reliance on coal in certain regions and industries, and the global shift towards cleaner energy sources. Technological innovations, regulatory developments, and market dynamics will continue to influence the market, presenting both challenges and opportunities for industry stakeholders.

Conclusion

In conclusion, the industrial coal burner sales market remains a vital component of various industrial processes, despite the growing emphasis on renewable energy. Industry players must navigate regulatory challenges, invest in technological advancements, and explore new market opportunities to sustain growth and competitiveness in this evolving market landscape.

Industrial Coal Burner Sales Market

| Segmentation Details | Description |

|---|---|

| Product Type | Fixed Coal Burners, Portable Coal Burners, High-Efficiency Burners, Multi-Fuel Burners |

| End User | Manufacturing Plants, Power Generation, Cement Industry, Steel Production |

| Technology | Combustion Control, Emission Reduction, Heat Recovery, Automated Systems |

| Installation | On-Site Installation, Pre-Configured Systems, Retrofit Solutions, Custom Installations |

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at