444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The Fuel Cell High Pressure Air Compressor market is experiencing significant growth as fuel cell technology gains traction as a clean and efficient energy solution. High-pressure air compressors play a crucial role in fuel cell systems by providing compressed air to the fuel cell stack for efficient power generation. These compressors enable the compression of ambient air to high pressures, which is essential for the operation of fuel cells in various applications, including transportation, stationary power generation, and portable devices. With increasing investments in hydrogen infrastructure and the deployment of fuel cell vehicles and power systems, the demand for high-pressure air compressors is on the rise.

Meaning

A Fuel Cell High Pressure Air Compressor refers to a device or system designed to compress ambient air to high pressures for use in fuel cell systems. These compressors typically operate at pressures ranging from several hundred to several thousand pounds per square inch (psi) and are essential components of fuel cell vehicles, stationary power plants, and other fuel cell applications. By delivering compressed air to the fuel cell stack, these compressors enable efficient and reliable power generation, making them critical components of fuel cell systems.

Executive Summary

The Fuel Cell High Pressure Air Compressor market is witnessing robust growth, driven by the increasing adoption of fuel cell technology in various applications, including transportation, stationary power generation, and portable devices. Key market players are investing in the development of advanced compressor technologies that offer higher efficiency, lower energy consumption, and improved reliability. These compressors play a vital role in enabling the widespread commercialization of fuel cell technology by providing the essential infrastructure for fuel cell systems to operate effectively and efficiently.

Key Market Insights

The Fuel Cell High Pressure Air Compressor market is characterized by technological advancements, increasing demand for clean and sustainable energy solutions, and supportive government policies and incentives. Key market players are focusing on developing compact, lightweight, and energy-efficient compressors that meet the performance requirements of fuel cell systems while reducing costs and improving reliability. Additionally, the integration of advanced materials, such as carbon fiber composites and lightweight alloys, is enabling the development of high-performance compressors with reduced weight and footprint.

Market Drivers

Several factors are driving the growth of the Fuel Cell High Pressure Air Compressor market, including:

Market Restraints

Despite the promising growth prospects, the Fuel Cell High Pressure Air Compressor market faces certain challenges, including:

Market Opportunities

The Fuel Cell High Pressure Air Compressor market presents significant opportunities for market players to capitalize on, including:

Market Dynamics

The Fuel Cell High Pressure Air Compressor market is characterized by dynamic market dynamics, driven by technological advancements, evolving customer preferences, and changing regulatory landscapes. Market players need to adapt to these changes by continuously innovating, investing in research and development, and expanding their product portfolios to meet the evolving needs of customers and stakeholders. Strategic partnerships, collaborations, and alliances with industry stakeholders, research institutions, and government agencies are essential for driving innovation, market penetration, and sustainable growth in the Fuel Cell High Pressure Air Compressor market.

Regional Analysis

The Fuel Cell High Pressure Air Compressor market is experiencing significant growth across regions, with Asia Pacific, Europe, and North America leading the market expansion. In Asia Pacific, countries such as Japan, South Korea, and China are driving market growth through investments in hydrogen infrastructure and fuel cell technology deployment, particularly in transportation and stationary power generation. In Europe, initiatives such as the European Green Deal and the Hydrogen Strategy are driving investments in hydrogen infrastructure and fuel cell applications, creating opportunities for high-pressure air compressor manufacturers. In North America, the United States and Canada are investing in hydrogen research, development, and deployment, with a focus on fuel cell vehicles, buses, and trucks.

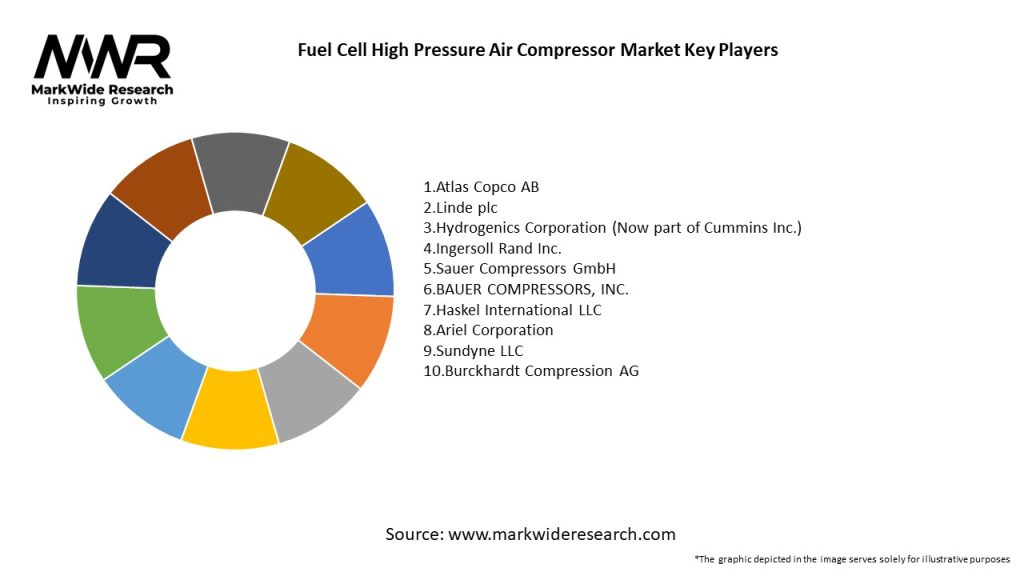

Competitive Landscape

The Fuel Cell High Pressure Air Compressor market is highly competitive, with key market players competing on factors such as compressor performance, efficiency, reliability, and cost-effectiveness. Major players operating in the market include Atlas Copco AB, Ingersoll Rand Inc., Gardner Denver Holdings Inc., Sauer Compressors USA Inc., and BAUER COMPRESSORS INC. These companies offer a range of high-pressure air compressors, including reciprocating compressors, rotary screw compressors, and centrifugal compressors, tailored to the specific requirements of fuel cell applications. Additionally, emerging players and start-ups are entering the market with innovative compressor technologies and solutions to address niche applications and market segments.

Segmentation

The Fuel Cell High Pressure Air Compressor market can be segmented based on compressor type, pressure range, application, and geography. By compressor type, the market can be segmented into reciprocating compressors, rotary screw compressors, and centrifugal compressors. By pressure range, the market can be segmented into low-pressure compressors (up to 500 psi), medium-pressure compressors (500-3000 psi), and high-pressure compressors (3000+ psi). By application, the market can be segmented into transportation, stationary power generation, portable power, and others. Geographically, the market can be segmented into North America, Europe, Asia Pacific, Latin America, and Middle East & Africa.

Category-wise Insights

In terms of compressor type, reciprocating compressors are the most widely used in fuel cell applications, owing to their simplicity, reliability, and cost-effectiveness. However, rotary screw compressors and centrifugal compressors are gaining traction in certain applications, such as large-scale stationary power generation and industrial processes, where higher flow rates and pressure ratios are required. In terms of pressure range, medium-pressure compressors are the most common in fuel cell applications, covering a wide range of operating pressures suitable for various fuel cell systems and applications. However, high-pressure compressors are also in demand for specific applications, such as hydrogen refueling stations and high-performance fuel cell vehicles.

Key Benefits for Industry Participants and Stakeholders

Fuel Cell High Pressure Air Compressors offer several key benefits for industry participants and stakeholders, including:

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Key trends shaping the Fuel Cell High Pressure Air Compressor market include:

Covid-19 Impact

The Covid-19 pandemic has had mixed impacts on the Fuel Cell High Pressure Air Compressor market, with both challenges and opportunities arising from the global crisis. On one hand, the pandemic has disrupted supply chains, delayed project timelines, and affected investment sentiment, leading to project cancellations and postponements in some regions. On the other hand, the pandemic has highlighted the importance of clean and sustainable energy solutions, driving investments in hydrogen infrastructure and fuel cell technology development and deployment. Governments, businesses, and investors are increasingly recognizing the economic, environmental, and social benefits of fuel cell technology, leading to renewed commitments and initiatives to promote its adoption and commercialization.

Key Industry Developments

Recent developments in the Fuel Cell High Pressure Air Compressor market include:

Analyst Suggestions

Industry analysts suggest that market players focus on the following strategies to capitalize on emerging opportunities and mitigate potential challenges in the Fuel Cell High Pressure Air Compressor market:

Future Outlook

The future outlook for the Fuel Cell High Pressure Air Compressor market remains highly promising, with continued growth expected in the coming years. Factors such as increasing investments in hydrogen infrastructure, growing adoption of fuel cell technology in transportation and stationary power generation, and supportive government policies and incentives are driving market demand for high-pressure air compressors. Additionally, technological advancements, such as advanced materials, digitalization, and automation, are enabling the development of more efficient, reliable, and sustainable compressors that meet the performance requirements of fuel cell systems and applications. As the world transitions towards clean and renewable energy sources, the Fuel Cell High Pressure Air Compressor market is expected to play a crucial role in enabling the widespread commercialization of fuel cell technology and accelerating the transition towards a more sustainable and resilient energy future.

Conclusion

In conclusion, the Fuel Cell High Pressure Air Compressor market is experiencing significant growth and transformation, driven by increasing investments in hydrogen infrastructure, growing adoption of fuel cell technology, and technological advancements in compressor design and manufacturing. These developments are creating significant opportunities for market players to capitalize on, including the expansion into emerging markets and applications, development of innovative compressor technologies, collaboration with industry stakeholders, and investment in research and development activities. Despite challenges such as regulatory uncertainties, technical complexities, and market competition, the Fuel Cell High Pressure Air Compressor market presents promising prospects for sustainable growth and development. By embracing technological innovations, fostering partnerships, and adopting customer-centric approaches, market players can position themselves for success and contribute to the transition towards a more sustainable and resilient energy future.

Fuel Cell High Pressure Air Compressor Market

| Segmentation Details | Description |

|---|---|

| Product Type | Diaphragm Compressors, Piston Compressors, Screw Compressors, Scroll Compressors |

| End User | Automotive OEMs, Aerospace, Industrial Manufacturing, Research Institutions |

| Technology | Electrochemical Compression, Mechanical Compression, Hybrid Systems, Cryogenic Compression |

| Application | Fuel Cell Vehicles, Stationary Power Generation, Portable Power Systems, Hydrogen Refueling Stations |

Leading Companies in the Fuel Cell High Pressure Air Compressor Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at