444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The cylindrical lithium battery winding machine market is witnessing substantial growth globally, driven by the increasing demand for lithium-ion batteries in various applications such as consumer electronics, electric vehicles, and energy storage systems. Lithium-ion batteries are widely used due to their high energy density, long cycle life, and fast charging capabilities. Cylindrical lithium battery winding machines play a crucial role in the manufacturing process of lithium-ion batteries by winding electrode materials onto cylindrical cores. With the growing emphasis on electrification, renewable energy, and energy storage solutions, the demand for cylindrical lithium battery winding machines is expected to continue rising across industries.

Meaning

Cylindrical lithium battery winding machines are specialized equipment used in the production of lithium-ion batteries. These machines are designed to wind electrode materials, such as cathodes and anodes, onto cylindrical cores to form the layers of a battery cell. The winding process is critical for ensuring uniformity, consistency, and integrity of the battery components, ultimately affecting the performance and reliability of the final product. Cylindrical lithium battery winding machines come in various configurations, ranging from manual to fully automated systems, and are essential for high-volume battery manufacturing operations.

Executive Summary

The global cylindrical lithium battery winding machine market is experiencing rapid growth, fueled by factors such as increasing demand for lithium-ion batteries, advancements in battery technology, and expansion of electric vehicle production. Key market players are investing in research and development to innovate and improve the performance, efficiency, and flexibility of winding machines, driving adoption rates across the battery manufacturing industry. Despite challenges such as technological complexities and supply chain disruptions, the cylindrical lithium battery winding machine market is poised for continued expansion driven by the transition towards electrification and renewable energy solutions.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The global cylindrical lithium battery winding machine market is characterized by dynamic factors that influence its growth trajectory. Market dynamics are shaped by factors such as technological advancements, regulatory changes, competitive landscape, and industry trends. Key drivers include increasing demand for lithium-ion batteries, advancements in battery technology, government incentives for electrification and energy storage, and technological advancements in winding machines. Challenges such as technical complexities, supply chain disruptions, regulatory uncertainties, and market competition may impact market growth and adoption rates.

Regional Analysis

The cylindrical lithium battery winding machine market is geographically diverse, with significant demand emanating from regions such as Asia Pacific, North America, Europe, Latin America, and Middle East & Africa. Asia Pacific dominates the market due to the presence of leading battery manufacturers, especially in countries like China, Japan, and South Korea. North America and Europe are witnessing growth driven by the expansion of electric vehicle production and investments in renewable energy and energy storage projects.

Competitive Landscape

The global cylindrical lithium battery winding machine market is highly competitive, with numerous players competing on factors such as technology leadership, product quality, reliability, and aftersales service. Key players in the market include Targray, Winding Solutions Ltd., Shenzhen Yuanming Industrial Development Co., Ltd., Neware Technology Limited, and Zeta Corporation, among others. These companies are focusing on innovation, research and development, and strategic partnerships to gain a competitive edge and expand their market presence.

Segmentation

The cylindrical lithium battery winding machine market can be segmented based on machine type, automation level, application, and region. By machine type, the market includes manual, semi-automatic, and fully automatic winding machines. Automation levels range from basic manual operation to fully integrated robotic systems. Applications of cylindrical lithium battery winding machines span electric vehicles, consumer electronics, energy storage systems, and others. Geographically, the market spans Asia Pacific, North America, Europe, Latin America, and Middle East & Africa.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic has had mixed effects on the cylindrical lithium battery winding machine market. While lockdowns and supply chain disruptions have led to delays in equipment procurement and manufacturing operations, the pandemic has also underscored the importance of electrification, renewable energy, and energy storage solutions for resilience and sustainability. As businesses and governments prioritize economic recovery and environmental protection, there is renewed focus on investing in battery manufacturing equipment and technologies to support electrification initiatives and drive growth in the battery industry.

Key Industry Developments

Analyst Suggestions

Future Outlook

The global cylindrical lithium battery winding machine market is expected to witness strong growth in the coming years, driven by factors such as increasing demand for lithium-ion batteries, advancements in battery technology, and expansion of electric vehicle production. Key trends such as the adoption of automation, integration of Industry 4.0 technologies, development of modular production lines, and emphasis on sustainability and environmental stewardship are expected to shape the market landscape. However, challenges such as technical complexities, supply chain disruptions, regulatory uncertainties, and market competition may impact market dynamics and growth potential.

Conclusion

In conclusion, the global cylindrical lithium battery winding machine market presents significant opportunities for businesses and stakeholders seeking to address the growing demand for lithium-ion batteries in various applications. With the right strategies and investments in place, market players can capitalize on emerging trends and technologies to drive innovation, efficiency, and sustainability in the battery manufacturing industry. As the market continues to evolve, collaboration and partnerships will be key to unlocking the full potential of cylindrical lithium battery winding machines and driving sustainable growth in battery production and electrification initiatives.

Cylindrical Lithium Battery Winding Machine Market Segmentation Table

| Segment | Details |

|---|---|

| Type | Manual Winding Machines, Automatic Winding Machines, Semi-automatic Winding Machines |

| Battery Type | 18650 Battery Winding Machines, 21700 Battery Winding Machines, Others |

| End User | Battery Manufacturers, Research Institutes, Electronics Industry |

| Region | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

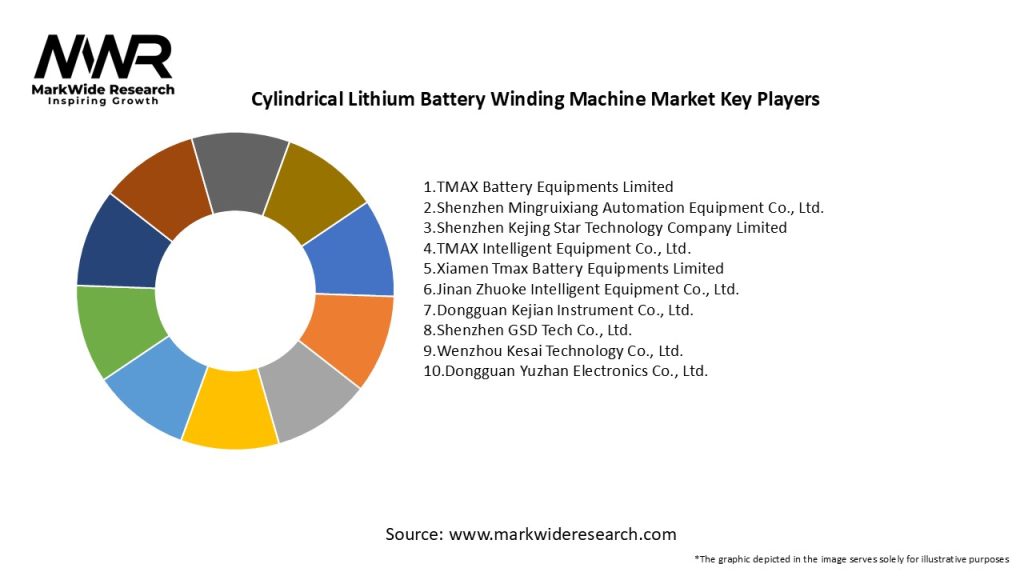

Leading Companies in the Cylindrical Lithium Battery Winding Machine Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at