444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The Refractory Mortar market is witnessing steady growth, driven by the increasing demand for high-temperature resistant materials in various industries such as steel, cement, glass, and ceramics. Refractory mortar, a specialized type of mortar designed to withstand extreme heat, is essential for the construction and maintenance of furnaces, kilns, reactors, and other high-temperature equipment. With the growing emphasis on energy efficiency, sustainability, and advanced manufacturing techniques, the market for refractory mortar is expected to continue expanding. Key market players are focusing on product innovation, customization, and strategic partnerships to meet the evolving needs of customers and gain a competitive edge.

Meaning

Refractory mortar refers to a specialized type of mortar designed to withstand high temperatures and harsh conditions. Composed of high-temperature resistant materials such as silica, alumina, and fireclay, refractory mortar is used in the construction and maintenance of furnaces, kilns, reactors, and other high-temperature equipment. Unlike conventional mortar, refractory mortar can withstand temperatures exceeding 2000°C (3632°F) without losing its strength or integrity. It is essential for bonding refractory bricks, tiles, and other heat-resistant materials in industrial applications where extreme heat is generated. With its ability to provide superior thermal insulation and resistance to thermal shock, refractory mortar plays a critical role in enhancing the performance and longevity of high-temperature equipment.

Executive Summary

The Refractory Mortar market is experiencing steady growth, driven by the increasing demand for high-temperature resistant materials in industries such as steel, cement, glass, and ceramics. Key market players are investing in product innovation, customization, and strategic partnerships to meet the evolving needs of customers and gain a competitive edge. With the growing emphasis on energy efficiency, sustainability, and advanced manufacturing techniques, the market for refractory mortar is expected to continue expanding. Manufacturers are focusing on enhancing product performance, reliability, and cost-effectiveness to meet the growing demand and gain a competitive edge in the market.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The Refractory Mortar market is characterized by steady growth, driven by the increasing demand for high-temperature resistant materials in industries such as steel, cement, glass, and ceramics. Key market players are investing in product innovation, customization, and strategic partnerships to meet the evolving needs of customers and gain a competitive edge. Additionally, strategic alliances, mergers and acquisitions, and joint ventures are driving market consolidation and expansion into new geographical markets and end-use segments. With the growing emphasis on energy efficiency, sustainability, and advanced manufacturing techniques, the market for refractory mortar is expected to continue expanding. Manufacturers are focusing on enhancing product performance, reliability, and cost-effectiveness to meet the growing demand and gain a competitive edge in the market.

Regional Analysis

North America is the largest market for Refractory Mortar, driven by the region’s significant presence in industries such as steel manufacturing, cement production, and glassmaking. Countries such as the United States and Canada are major consumers of refractory mortar for the construction and maintenance of high-temperature equipment. Europe and Asia Pacific are also significant markets, with growing industrialization, infrastructure development, and investments in energy efficiency driving the demand for refractory materials. Latin America and the Middle East & Africa are witnessing increasing adoption of refractory mortar, fueled by economic growth, urbanization, and industrial expansion.

Competitive Landscape

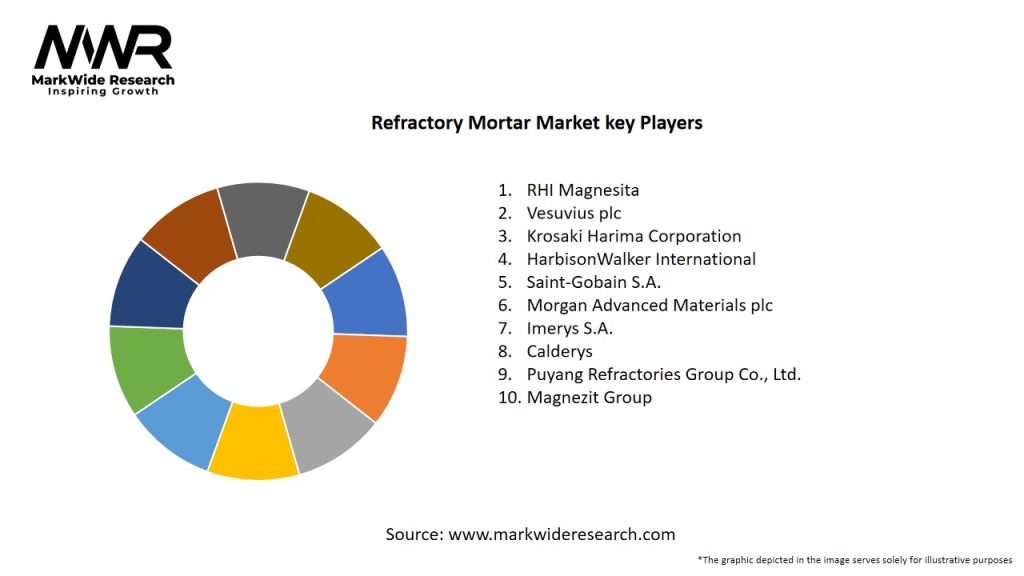

The Refractory Mortar market is highly competitive, with several key players dominating the global landscape. Major companies operating in the market include Calderys, Morgan Advanced Materials, HarbisonWalker International, Rath Group, and Saint-Gobain. These companies offer a wide range of refractory mortar products, including conventional, low-cement, and ultra-low cement formulations, for various industrial applications. Key market players are focusing on product innovation, customization, and strategic partnerships to meet the evolving needs of customers and gain a competitive edge. Additionally, mergers and acquisitions, joint ventures, and collaborations are driving market consolidation and expansion into new geographical markets and end-use segments.

Segmentation

The Refractory Mortar market can be segmented based on product type, temperature range, application, end-use industry, and geography. By product type, the market is categorized into conventional, low-cement, and ultra-low cement refractory mortars. Based on temperature range, the market is divided into low, medium, and high-temperature refractory mortars. By application, the market is segmented into furnace linings, kiln coatings, boiler insulation, and others. By end-use industry, the market is categorized into steel, cement, glass, ceramics, and others. Geographically, the market is segmented into North America, Europe, Asia Pacific, Latin America, and Middle East & Africa.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic has had a mixed impact on the Refractory Mortar market. While disruptions in supply chains, manufacturing operations, and construction activities initially led to a decline in sales and consumption of refractory materials, particularly in industries such as steel and cement, the market has witnessed a gradual recovery as economies reopen and industrial activities resume. Additionally, the pandemic has highlighted the importance of high-temperature resistant materials in ensuring the reliability and efficiency of industrial processes. With the growing emphasis on energy efficiency, sustainability, and advanced manufacturing techniques, the future outlook for the Refractory Mortar market looks promising, with ample opportunities for growth and innovation.

Key Industry Developments

Analyst Suggestions

Future Outlook

The Refractory Mortar market is expected to continue growing steadily in the coming years, driven by the increasing demand for high-temperature resistant materials in industries such as steel, cement, glass, and ceramics. Key market players are likely to focus on product innovation, customization, and strategic partnerships to meet the evolving needs of customers and gain a competitive edge. With the growing emphasis on energy efficiency, sustainability, and advanced manufacturing techniques, the market for refractory mortar is expected to continue expanding. Manufacturers are focusing on enhancing product performance, reliability, and cost-effectiveness to meet the growing demand and gain a competitive edge in the market.

Conclusion

In conclusion, the Refractory Mortar market is witnessing steady growth, driven by the increasing demand for high-temperature resistant materials in various industries such as steel, cement, glass, and ceramics. Key market players are investing in product innovation, customization, and strategic partnerships to meet the evolving needs of customers and gain a competitive edge. With the growing emphasis on energy efficiency, sustainability, and advanced manufacturing techniques, the market for refractory mortar is expected to continue expanding. Manufacturers are focusing on enhancing product performance, reliability, and cost-effectiveness to meet the growing demand and gain a competitive edge in the market.

Refractory Mortar Market

| Segmentation Details | Description |

|---|---|

| Product Type | Castable, Plastic, Ramming, Trowelable |

| Application | Industrial Furnaces, Boilers, Kilns, Incinerators |

| End User | Cement, Metal, Glass, Petrochemical |

| Form | Dry Mix, Wet Mix, Pre-Mixed, Ready-to-Use |

Leading Companies in Refractory Mortar Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at