444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The duplicating films market is experiencing steady growth globally, driven by the increasing demand for high-quality reproduction of images, texts, and graphics in various industries. Duplicating films, also known as duplicating masters or stencil films, are essential consumables used in printing, screen printing, and stencil-making processes. These films offer precise image reproduction, excellent durability, and compatibility with a wide range of printing and imaging technologies, making them indispensable tools for graphic design, signage, packaging, and industrial applications.

Meaning

Duplicating films are thin, transparent sheets made of materials such as polyester, acetate, or PVC (polyvinyl chloride), coated with light-sensitive emulsions or coatings. These films are used to create master copies or stencils for duplicating images, texts, or patterns onto various substrates such as paper, fabric, plastic, or metal. Duplicating films are available in different thicknesses, sizes, and formulations to accommodate specific printing techniques and applications, including screen printing, offset printing, lithography, and digital printing.

Executive Summary

The global duplicating films market is witnessing steady growth, driven by factors such as increasing demand for customized printing solutions, growing adoption of digital printing technologies, and rising demand from end-user industries such as packaging, advertising, textiles, and electronics. Key market players are focusing on product innovation, technological advancements, and strategic partnerships to expand their product portfolios and gain a competitive edge in the market. Moreover, investments in research and development, quality assurance, and customer service are driving market growth and differentiation.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The global duplicating films market is characterized by dynamic trends, evolving customer preferences, and competitive pressures. Market players are focusing on product innovation, technological advancements, and strategic partnerships to stay ahead of the competition and capture market share. Moreover, investments in research and development, quality assurance, and customer service are driving market differentiation and growth. The growing emphasis on environmental sustainability, regulatory compliance, and safety standards is reshaping the industry landscape, with brands seeking to position themselves as responsible stewards of the environment and trusted partners for their customers.

Regional Analysis

The duplicating films market is geographically diversified, with key regions including North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. North America and Europe are major markets for duplicating films, driven by the presence of established printing industries, technological advancements, and high demand for customized printing solutions. Asia Pacific is witnessing rapid market growth, fueled by increasing investments in printing infrastructure, rising disposable incomes, and growing demand from end-user industries such as packaging, textiles, and electronics. Latin America and Middle East & Africa offer untapped market potential, with opportunities for brands to expand their presence and reach new customers in emerging markets.

Competitive Landscape

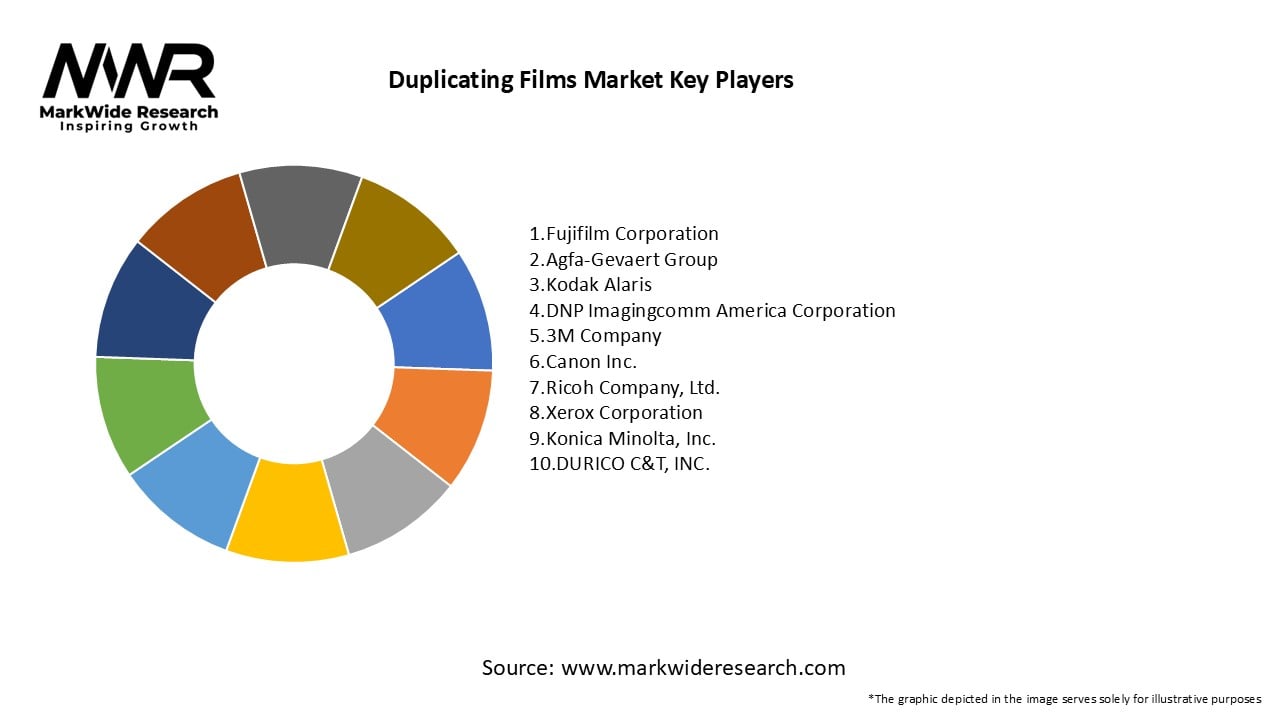

The global duplicating films market is highly competitive, with a mix of multinational corporations, regional players, and small to medium-sized enterprises competing for market share. Key players in the market include 3M Company, DuPont de Nemours, Inc., Agfa-Gevaert Group, Fujifilm Holdings Corporation, and Kodak Alaris. These companies offer a wide range of duplicating films for different printing techniques and applications, along with complementary products such as printing equipment, inks, and software solutions. Innovation in materials, formulations, and manufacturing processes is key to staying competitive in the dynamic duplicating films market, as brands seek to address evolving customer needs and market trends.

Segmentation

The duplicating films market can be segmented based on material type, printing technique, application, and end-user industry. By material type, duplicating films are available in polyester, acetate, PVC, and other plastic films. Printing techniques for duplicating films include screen printing, offset printing, digital printing, and stencil-making processes. Applications for duplicating films encompass graphic design, signage, packaging, textiles, electronics, and industrial manufacturing. End-user industries for duplicating films include printing and publishing, advertising and marketing, packaging and labeling, textiles and apparel, electronics and semiconductors, and automotive and aerospace.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic has had a mixed impact on the duplicating films market. While the temporary closure of businesses and disruptions in supply chains initially affected sales, the shift towards remote work, online shopping, and e-commerce has fueled demand for printing consumables such as duplicating films. Moreover, the growing emphasis on hygiene, safety, and contactless transactions has led to increased demand for packaging, labeling, and signage solutions, driving the adoption of printing technologies and consumables.

Key Industry Developments

Analyst Suggestions

Future Outlook

The global duplicating films market is expected to continue its growth trajectory, driven by factors such as increasing demand for customized printing solutions, technological advancements in printing technologies, and growing awareness of environmental sustainability and safety standards. Market players are focusing on product innovation, collaboration, and differentiation to stay ahead of the competition and capture market share. Moreover, investments in research and development, quality assurance, and customer service are driving market growth and competitiveness in the dynamic and evolving duplicating films market.

Conclusion

In conclusion, the duplicating films market offers lucrative opportunities for manufacturers, suppliers, and stakeholders across various industries and applications. With increasing demand for high-quality reproduction of images, texts, and graphics, and growing adoption of digital printing technologies and on-demand production processes, duplicating films are poised to play a crucial role in the printing and imaging industry. By focusing on product innovation, customization, and sustainability, market players can capitalize on emerging trends and drive long-term growth and success in the competitive global market landscape.

Duplicating Films Market

| Segmentation Details | Description |

|---|---|

| Product Type | Black & White, Color, Reversal, Negative |

| Application | Photography, Cinematography, Graphic Arts, Industrial |

| End User | Professional Photographers, Film Studios, Advertising Agencies, Educational Institutions |

| Distribution Channel | Online Retail, Specialty Stores, Wholesale Distributors, Direct Sales |

Leading Companies in Duplicating Films Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at