444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview: The Medical Instruments Packing Tables Market is an integral segment within the healthcare industry, providing essential equipment for packing, organizing, and sterilizing medical instruments and supplies. These specialized tables are designed to meet the unique needs of medical facilities, including hospitals, clinics, surgical centers, and dental practices, ensuring efficient workflow, infection control, and patient safety in healthcare settings.

Meaning: Medical instruments packing tables are specifically designed workstations or surfaces equipped with features such as integrated storage compartments, shelving units, drawers, and trays to facilitate the packing, assembly, and sterilization of medical instruments, surgical tools, and supplies. These tables play a crucial role in healthcare facilities by providing a designated area for instrument preparation, organization, and packaging before sterilization and use in clinical procedures.

Executive Summary: The Medical Instruments Packing Tables Market is witnessing steady growth driven by increasing demand for infection control, workflow optimization, and regulatory compliance in healthcare settings. These tables offer healthcare facilities a dedicated workspace for instrument packing and sterilization, enhancing operational efficiency, infection prevention, and patient safety. With the rising emphasis on healthcare quality and safety, medical instruments packing tables have become essential equipment in modern healthcare facilities.

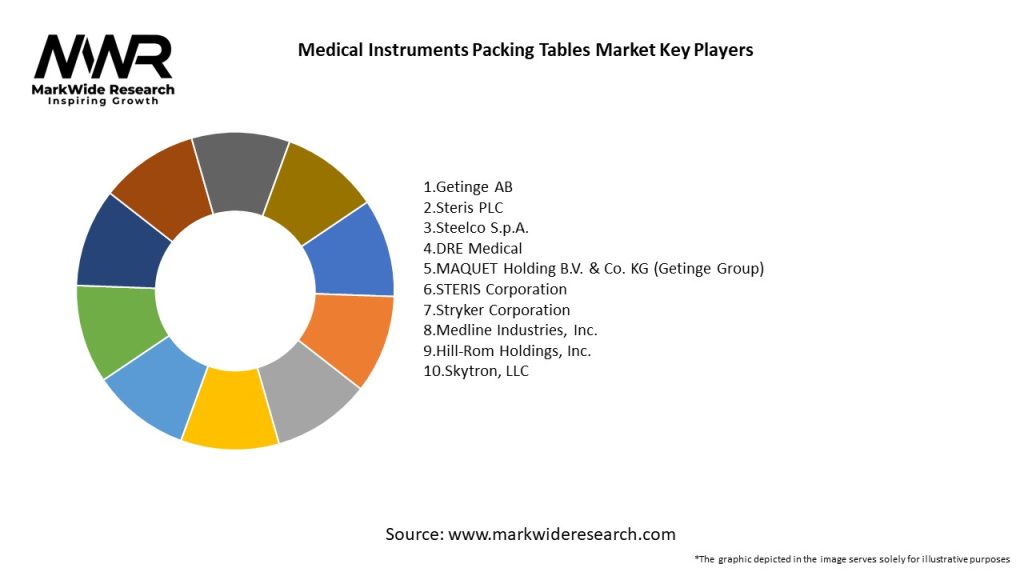

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights:

Market Drivers:

Market Restraints:

Market Opportunities:

Market Dynamics: The Medical Instruments Packing Tables Market operates in a dynamic environment influenced by factors such as technological innovation, regulatory changes, healthcare infrastructure development, and market competition, driving product evolution, differentiation, and strategic partnerships among industry stakeholders.

Regional Analysis: The market for Medical Instruments Packing Tables exhibits regional variations in market size, adoption rates, regulatory frameworks, and healthcare infrastructure development. Developed regions such as North America and Europe lead in market maturity and adoption of medical device reprocessing solutions, driven by stringent regulatory standards and a strong focus on infection control and patient safety. Emerging markets in Asia Pacific and Latin America offer growth opportunities fueled by increasing healthcare expenditure, rising awareness of HAIs, and investments in healthcare infrastructure.

Competitive Landscape:

Leading Companies in the Medical Instruments Packing Tables Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

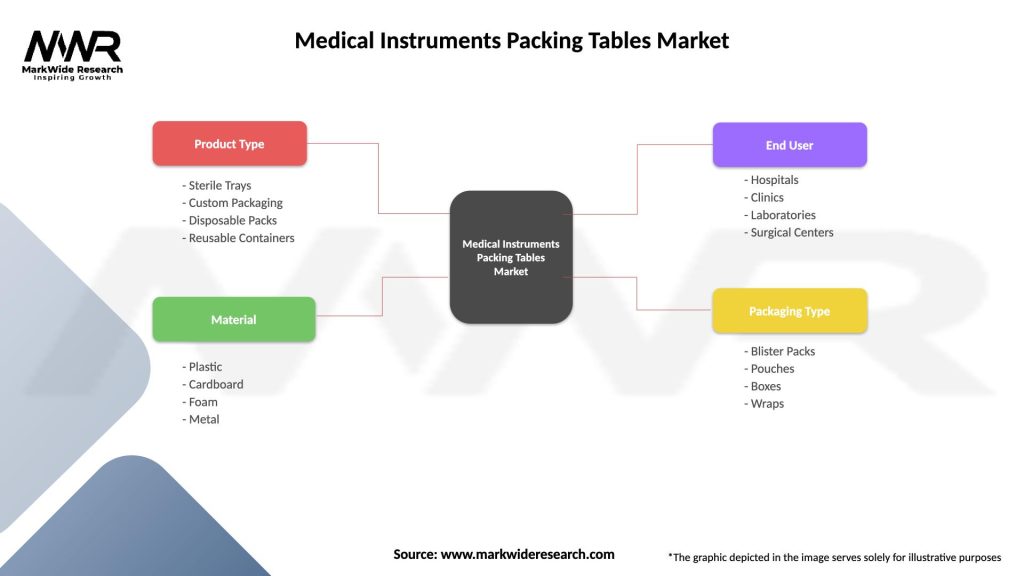

Segmentation: The Medical Instruments Packing Tables Market can be segmented based on:

Category-wise Insights:

Key Benefits for Industry Participants and Stakeholders:

SWOT Analysis:

Market Key Trends:

Covid-19 Impact: The COVID-19 pandemic has underscored the importance of infection prevention and control in healthcare settings, driving demand for medical instruments packing tables and sterile processing solutions to support the increased volume of surgical procedures, diagnostic testing, and patient care activities. Medical instruments packing tables have played a critical role in facilitating the safe and efficient reprocessing of medical instruments and supplies for COVID-19 patient care and treatment, accelerating market adoption and innovation amidst the global health crisis.

Key Industry Developments:

Analyst Suggestions:

Future Outlook: The Medical Instruments Packing Tables Market is poised for continued growth driven by increasing demand for infection control, workflow optimization, and regulatory compliance in healthcare settings. Market players should focus on innovation, customization, and collaboration to address evolving customer needs, technological challenges, and market dynamics, driving sustainable growth and competitive advantage in the global Medical Instruments Packing Tables Market.

Conclusion: Medical instruments packing tables play a vital role in infection prevention, workflow efficiency, and regulatory compliance in healthcare settings, providing designated workstations for instrument packing, organization, and sterilization. The Medical Instruments Packing Tables Market is characterized by technological innovation, regulatory complexity, and evolving customer requirements, driving market growth, product development, and strategic initiatives among industry stakeholders. By addressing market challenges, fostering innovation, and collaborating with stakeholders, industry players can enhance market competitiveness, meet customer needs, and drive sustainable growth in the global Medical Instruments Packing Tables Market.

What is Medical Instruments Packing Tables?

Medical Instruments Packing Tables are specialized work surfaces designed for the efficient packing and preparation of medical instruments. They are essential in healthcare settings to ensure that instruments are organized, sterilized, and ready for use in surgical and medical procedures.

What are the key players in the Medical Instruments Packing Tables Market?

Key players in the Medical Instruments Packing Tables Market include companies like Aesculap, Getinge, and Steris, which provide a range of packing solutions for medical instruments. These companies focus on innovation and quality to meet the needs of healthcare facilities, among others.

What are the growth factors driving the Medical Instruments Packing Tables Market?

The growth of the Medical Instruments Packing Tables Market is driven by the increasing demand for efficient surgical procedures and the rising focus on infection control in healthcare settings. Additionally, advancements in packing technology and the expansion of healthcare facilities contribute to market growth.

What challenges does the Medical Instruments Packing Tables Market face?

The Medical Instruments Packing Tables Market faces challenges such as the high cost of advanced packing systems and the need for regular maintenance and training. Additionally, varying regulations across regions can complicate compliance for manufacturers.

What opportunities exist in the Medical Instruments Packing Tables Market?

Opportunities in the Medical Instruments Packing Tables Market include the development of smart packing solutions that integrate technology for better tracking and sterilization. Furthermore, the growing trend of minimally invasive surgeries is expected to increase the demand for specialized packing tables.

What trends are shaping the Medical Instruments Packing Tables Market?

Trends in the Medical Instruments Packing Tables Market include the adoption of ergonomic designs to enhance user comfort and efficiency. Additionally, there is a growing emphasis on sustainability, with manufacturers exploring eco-friendly materials and practices in the production of packing tables.

Medical Instruments Packing Tables Market

| Segmentation Details | Description |

|---|---|

| Product Type | Sterile Trays, Custom Packaging, Disposable Packs, Reusable Containers |

| Material | Plastic, Cardboard, Foam, Metal |

| End User | Hospitals, Clinics, Laboratories, Surgical Centers |

| Packaging Type | Blister Packs, Pouches, Boxes, Wraps |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Medical Instruments Packing Tables Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at