444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview: The sterility testing pump market is a crucial segment of the healthcare industry, catering to the stringent requirements for ensuring the sterility of pharmaceutical and medical device products. Sterility testing pumps play a vital role in quality control processes by facilitating the detection of microbial contamination in pharmaceutical preparations, injectable drugs, medical devices, and sterile products. As the demand for safe and effective healthcare products continues to rise, the sterility testing pump market experiences steady growth driven by advancements in technology, stringent regulatory standards, and increasing focus on patient safety.

Meaning: sterility testing pumps are specialized instruments used to generate the required vacuum for the sterility testing of pharmaceuticals and medical devices. These pumps create a controlled environment conducive to microbial growth, allowing for the detection of microbial contamination in samples. Sterility testing pumps are designed to meet the specific requirements of regulatory authorities such as the United States Pharmacopeia (USP), European Pharmacopoeia (EP), and other global regulatory bodies governing the sterility testing of pharmaceutical products and medical devices.

Executive Summary: The sterility testing pump market is characterized by a growing emphasis on product quality, regulatory compliance, and patient safety. Key market players focus on developing innovative, reliable, and user-friendly sterility testing pumps that meet the stringent requirements of pharmaceutical manufacturers, contract testing laboratories, and regulatory authorities. With advancements in technology, automation, and data integrity, sterility testing pumps are poised to play an increasingly critical role in ensuring the sterility and safety of healthcare products in the global market.

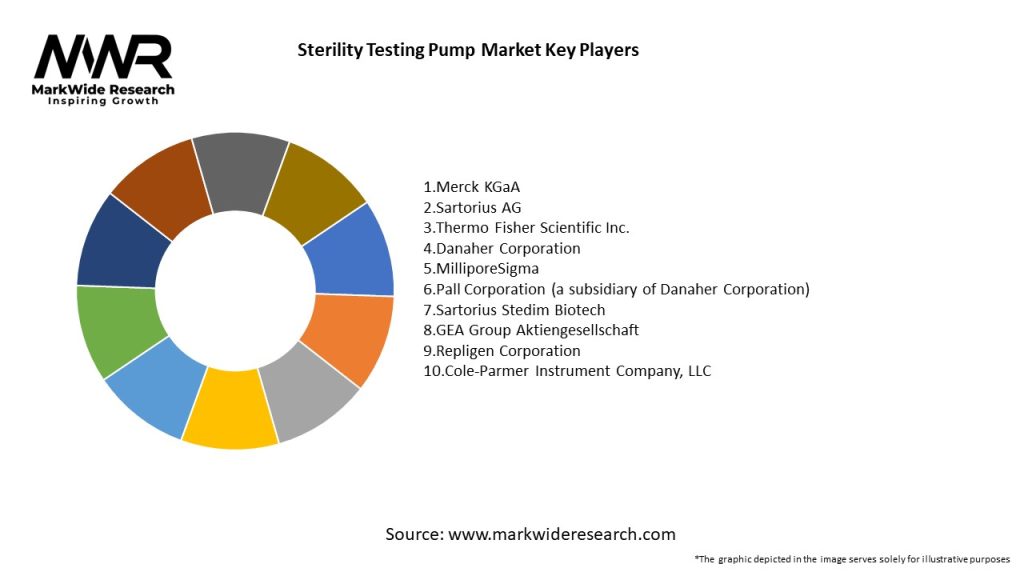

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights:

Market Drivers:

Market Restraints:

Market Opportunities:

Market Dynamics: The sterility testing pump market operates in a dynamic environment shaped by factors such as technological innovation, regulatory evolution, market competition, and industry trends. Market players must navigate challenges such as regulatory compliance, cost pressures, and operational complexities while capitalizing on opportunities in emerging markets, outsourcing trends, and technological innovation to drive growth, differentiation, and sustainability in the market.

Regional Analysis: The sterility testing pump market exhibits regional variations in market dynamics, regulatory frameworks, and industry practices influenced by factors such as healthcare infrastructure, economic conditions, and regulatory priorities. Developed regions such as North America and Europe lead the market in terms of technological innovation, regulatory compliance, and healthcare expenditures, while emerging markets in Asia Pacific, Latin America, and Middle East offer growth opportunities driven by increasing pharmaceutical manufacturing activities and adoption of international quality standards.

Competitive Landscape: The sterility testing pump market is characterized by a competitive landscape comprising a mix of global and regional players specializing in sterility testing pumps, laboratory equipment, and analytical instrumentation. Key competitive strategies include product differentiation, regulatory compliance, customer support, and strategic partnerships aimed at gaining market share, expanding product portfolios, and enhancing brand reputation in the global market.

Segmentation: The sterility testing pump market can be segmented based on various factors such as product type, technology, end-user, and geographical regions. Common segmentation categories include peristaltic pumps, membrane pumps, vacuum filtration pumps, manual vs. automated pumps, pharmaceutical vs. contract testing laboratories, North America vs. Europe vs. Asia Pacific markets, among others.

Category-wise Insights:

Key Benefits for Industry Participants and Stakeholders:

SWOT Analysis: A SWOT analysis provides insights into the strengths, weaknesses, opportunities, and threats facing the sterility testing pump market:

Market Key Trends:

Covid-19 Impact: The Covid-19 pandemic has underscored the importance of sterility testing in ensuring the safety and efficacy of pharmaceutical products, medical devices, and personal protective equipment (PPE) used in pandemic response efforts. Sterility testing pump manufacturers have experienced increased demand for pumps and related equipment to support Covid-19 vaccine production, testing, and distribution, highlighting the critical role of sterility testing in public health emergencies.

Key Industry Developments:

Analyst Suggestions:

Future Outlook: The future outlook for the sterility testing pump market remains positive, driven by factors such as technological innovation, regulatory evolution, and market demand for safe and effective healthcare products. While challenges such as regulatory compliance, operational complexity, and market competition persist, strategic initiatives focused on innovation, collaboration, and customer engagement will shape the future of the sterility testing pump market, ensuring continued growth, differentiation, and value creation for industry stakeholders.

Conclusion: In conclusion, the sterility testing pump market plays a critical role in ensuring the safety, efficacy, and quality of pharmaceutical products, medical devices, and sterile preparations in the healthcare industry. With advancements in technology, automation, and regulatory compliance, sterility testing pumps enable pharmaceutical manufacturers, contract testing laboratories, and regulatory authorities to meet the stringent requirements for sterility testing and quality assurance. Industry stakeholders must navigate challenges, capitalize on opportunities, and drive innovation to address unmet needs, market trends, and regulatory requirements, ensuring the continued growth, relevance, and sustainability of the sterility testing pump market in the global healthcare ecosystem.

Sterility Testing Pump Market

| Segmentation Details | Description |

|---|---|

| Product Type | Positive Displacement Pumps, Peristaltic Pumps, Vacuum Pumps, Centrifugal Pumps |

| End User | Pharmaceutical Companies, Biotechnology Firms, Research Laboratories, Hospitals |

| Application | Microbial Testing, Sterility Assurance, Quality Control, Environmental Monitoring |

| Technology | Automated Systems, Manual Systems, Hybrid Systems, Digital Monitoring |

Leading Companies in the Sterility Testing Pump Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at