444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview The CI Flexographic Press market stands as a cornerstone of the printing industry, offering high-speed, high-quality printing solutions for flexible packaging materials. CI Flexographic Presses, characterized by their central impression drum design, cater to a diverse range of industries, including food and beverage, pharmaceuticals, and consumer goods. With their ability to deliver superior print quality, operational efficiency, and versatility, CI Flexographic Presses occupy a pivotal position in the global printing landscape.

Meaning CI Flexographic Presses, short for Central Impression Flexographic Presses, represent a specialized category of printing equipment designed for the production of flexible packaging materials. These presses feature a central impression drum around which the printing substrates are wrapped, ensuring precise registration and consistent print quality. CI Flexographic Presses leverage flexographic printing technology to transfer ink onto a variety of substrates, including plastic films, paper, and labels, catering to the diverse needs of packaging manufacturers and converters worldwide.

Executive Summary The CI Flexographic Press market thrives on the convergence of technological innovation, evolving consumer preferences, and the burgeoning demand for flexible packaging solutions. As industries gravitate towards sustainable packaging alternatives and high-quality print finishes, CI Flexographic Presses emerge as the preferred choice for manufacturers seeking to enhance brand visibility, product differentiation, and operational efficiency. However, amidst the surge in demand, challenges such as technological obsolescence, supply chain disruptions, and regulatory compliance loom large, necessitating strategic foresight and adaptive resilience from market participants.

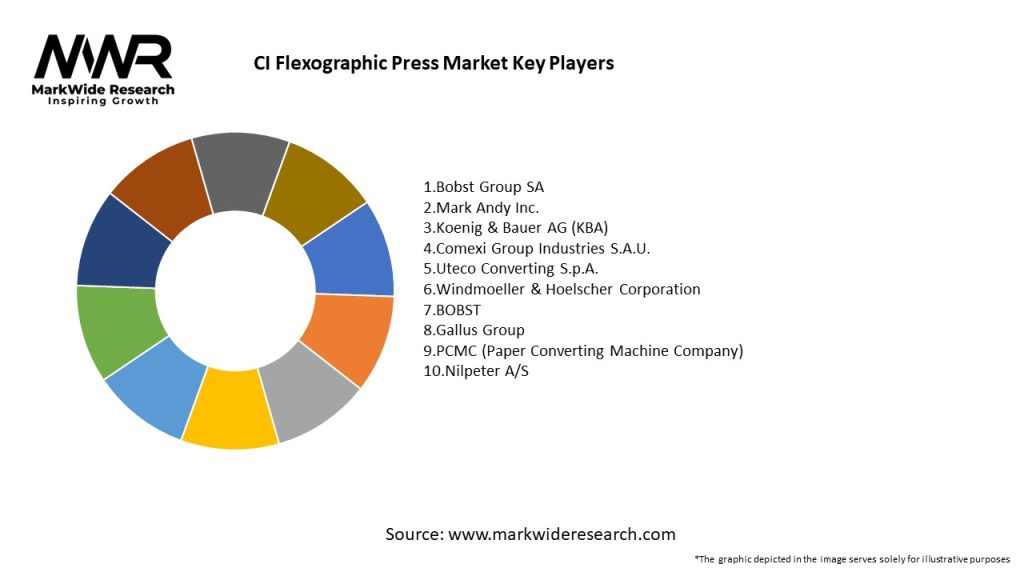

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics The CI Flexographic Press market operates within a dynamic ecosystem characterized by technological innovation, evolving market dynamics, and shifting consumer preferences. From the pursuit of operational excellence to the quest for sustainable innovation, CI Flexographic Press manufacturers navigate a myriad of opportunities and challenges to maintain market leadership and drive growth.

Regional Analysis The CI Flexographic Press market exhibits regional variations driven by factors such as market maturity, regulatory landscape, and industry dynamics. From the established markets of North America and Europe to the burgeoning economies of Asia-Pacific and Latin America, each region presents unique opportunities and challenges for CI Flexographic Press manufacturers seeking to expand their global footprint and capture market share.

Competitive Landscape

Leading Companies in the CI Flexographic Press Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation The CI Flexographic Press market can be segmented based on various factors, including product type, application, end-user industry, and geographic region. From stack-type presses to inline presses and wide-web presses, segmentation enables manufacturers to tailor their product offerings to specific customer needs and market segments, driving revenue growth and market penetration.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Strengths

• The CI flexographic press market benefits from advanced printing technology that allows for high-speed production and superior print quality, making it ideal for packaging applications.

• Strong demand from the packaging industry, particularly in flexible packaging, drives growth and innovation in CI flexographic press designs and functionalities.

• The ability to print on a variety of substrates, including films and paper, enhances the versatility of CI flexographic presses, catering to diverse customer needs.

• Established relationships with suppliers and a robust distribution network contribute to the market’s stability and facilitate timely delivery of components and services.

Weaknesses

• High initial investment costs for CI flexographic presses can deter smaller companies from entering the market, limiting overall market growth potential.

• The complexity of maintaining and operating CI flexographic presses requires skilled labor, which can lead to workforce challenges and increased operational costs.

• Dependence on the fluctuating prices of raw materials, such as inks and substrates, can impact profit margins and pricing strategies within the market.

• Limited awareness of the benefits of CI flexographic printing among end-users in certain sectors may restrict market penetration and adoption rates.

Opportunities

• Growing consumer preference for sustainable packaging solutions presents opportunities for CI flexographic presses that utilize eco-friendly inks and materials.

• The expansion of e-commerce and online retailing is increasing demand for efficient and high-quality packaging solutions, driving further adoption of CI flexographic technology.

• Technological advancements, such as automation and digital integration, offer potential for enhanced efficiency and reduced waste in CI flexographic printing processes.

• Emerging markets in developing regions are witnessing rapid industrialization, creating new avenues for growth in the CI flexographic press market.

Threats

• Intense competition from alternative printing technologies, such as digital printing, poses a significant challenge to the growth of the CI flexographic press market.

• Regulatory changes and increasing environmental standards may impose additional compliance costs on manufacturers, impacting profitability.

Market Key Trends

Covid-19 Impact The Covid-19 pandemic exerted profound ramifications on the CI Flexographic Press market, disrupting supply chains, dampening demand, and reshaping consumer behavior. From the surge in e-commerce packaging to the shift towards sustainable solutions, Covid-19 accelerated pre-existing trends and catalyzed innovation, adaptation, and resilience across the CI Flexographic Press ecosystem.

Key Industry Developments

Analyst Suggestions

Future Outlook The future of the CI Flexographic Press market is characterized by technological innovation, sustainable transformation, and digital integration, offering manufacturers unprecedented opportunities for growth, differentiation, and value creation. From the pursuit of operational excellence to the embrace of sustainable practices, CI Flexographic Press manufacturers navigate a dynamic landscape shaped by market dynamics, consumer preferences, and regulatory imperatives, charting a course towards a future defined by relevance, resilience, and digital supremacy.

Conclusion In conclusion, the CI Flexographic Press market stands at the nexus of technological innovation, sustainable transformation, and market dynamics, offering manufacturers unparalleled opportunities for growth, differentiation, and value creation. From the pursuit of operational excellence to the embrace of digital integration and sustainable innovation, CI Flexographic Press manufacturers navigate a dynamic landscape shaped by market forces, consumer preferences, and regulatory imperatives, charting a course towards a future defined by relevance, resilience, and digital supremacy. By embracing innovation, collaboration, and sustainability, CI Flexographic Press manufacturers can harness the full potential of the market, driving growth, differentiation, and value creation in the digital age.

What is CI Flexographic Press?

CI Flexographic Press refers to a type of printing press that utilizes a flexible relief plate to transfer ink onto various substrates. It is commonly used in packaging, labels, and flexible materials due to its efficiency and high-quality output.

What are the key players in the CI Flexographic Press Market?

Key players in the CI Flexographic Press Market include companies like Bobst, Mark Andy, and Windmoeller & Hoelscher. These companies are known for their innovative technologies and extensive product offerings in the flexographic printing space, among others.

What are the growth factors driving the CI Flexographic Press Market?

The CI Flexographic Press Market is driven by the increasing demand for flexible packaging solutions and the rise in e-commerce activities. Additionally, advancements in printing technology and the need for sustainable packaging options are contributing to market growth.

What challenges does the CI Flexographic Press Market face?

Challenges in the CI Flexographic Press Market include the high initial investment costs and the need for skilled operators. Furthermore, competition from digital printing technologies poses a significant challenge to traditional flexographic printing methods.

What opportunities exist in the CI Flexographic Press Market?

Opportunities in the CI Flexographic Press Market include the growing trend towards sustainable packaging and the expansion of the food and beverage industry. Innovations in ink formulations and printing techniques also present avenues for growth.

What trends are shaping the CI Flexographic Press Market?

Trends in the CI Flexographic Press Market include the increasing adoption of automation and digital integration in printing processes. Additionally, there is a rising focus on eco-friendly inks and substrates, reflecting the industry’s shift towards sustainability.

CI Flexographic Press Market

| Segmentation Details | Description |

|---|---|

| Product Type | Inline Press, Central Impression Press, Stack Press, Hybrid Press |

| End User | Packaging Manufacturers, Label Printers, Corrugated Box Producers, Flexible Packaging Companies |

| Technology | Water-Based Ink, Solvent-Based Ink, UV Ink, Electron Beam Ink |

| Application | Food Packaging, Beverage Packaging, Labeling, Industrial Packaging |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the CI Flexographic Press Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at