Market Overview

The air plug gages market is an integral part of the precision measurement industry, offering accurate and efficient solutions for inspecting internal diameters and hole depths in various manufacturing processes. Air plug gages, also known as air rings or air gauges, utilize compressed air to measure the dimensional accuracy of machined parts with high repeatability and reliability. With advancements in manufacturing technology and increasing demand for quality control in industries such as automotive, aerospace, and medical devices, the air plug gages market is experiencing steady growth and innovation to meet the evolving needs of customers.

Meaning

Air plug gages are precision measurement tools used for checking the internal dimensions of bores, holes, and cylindrical components in manufacturing processes. They consist of a hollow cylindrical body with one or more sensing elements that detect variations in air pressure when inserted into a part under inspection. Air plug gages provide fast, non-contact measurement with high accuracy and repeatability, making them essential for quality assurance, process control, and dimensional verification in various industries.

Executive Summary

The air plug gages market is witnessing continuous growth driven by factors such as increasing demand for high-precision components, stringent quality standards, and the adoption of advanced manufacturing techniques. Market players are focusing on product innovation, technological advancements, and customer-centric solutions to address the evolving needs of industries such as automotive, aerospace, electronics, and medical devices. However, challenges such as pricing pressures, competition from alternative measurement methods, and regulatory compliance require strategic planning and collaboration to sustain growth and competitiveness in the market.

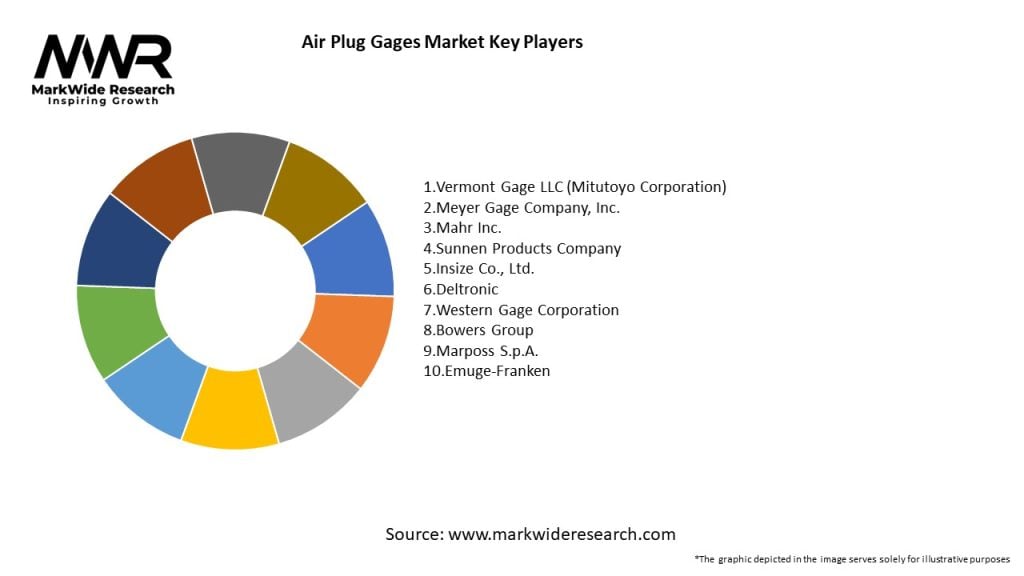

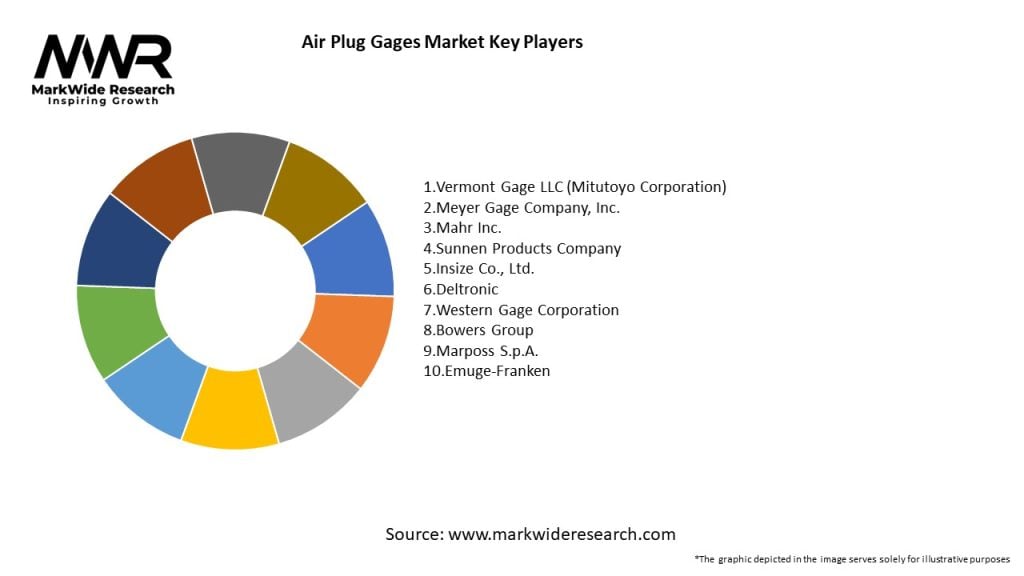

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

- Precision Manufacturing: The demand for air plug gages is driven by the need for precision manufacturing in industries such as automotive, aerospace, electronics, and medical devices, where tight tolerances and dimensional accuracy are critical for product performance and reliability.

- Quality Control: Air plug gages play a vital role in quality control and assurance processes, enabling manufacturers to verify the dimensional accuracy of machined parts, detect defects, and ensure compliance with customer specifications and regulatory standards.

- Non-Contact Measurement: The non-contact measurement capabilities of air plug gages offer advantages such as reduced wear and tear, faster inspection times, and avoidance of surface damage or contamination, making them suitable for delicate or sensitive components.

- Automation Integration: Integration with automation systems and Industry 4.0 technologies enables seamless integration of air plug gages into production lines, real-time data collection, and process optimization for improved efficiency and productivity.

Market Drivers

- Demand for Precision Components: The increasing demand for precision components in industries such as automotive, aerospace, and electronics drives the adoption of air plug gages for accurate dimensional measurement and quality assurance.

- Stringent Quality Standards: Stringent quality standards and regulatory requirements in industries such as medical devices and aerospace mandate the use of high-precision measurement tools like air plug gages to ensure product integrity and compliance.

- Advancements in Manufacturing Technology: Technological advancements in machining processes, such as CNC machining, EDM, and laser cutting, necessitate advanced measurement solutions like air plug gages to verify dimensional accuracy and maintain tight tolerances.

- Focus on Process Efficiency: Manufacturers are increasingly focused on improving process efficiency, reducing scrap, and minimizing rework by implementing reliable and efficient measurement techniques such as air plug gages for in-process and post-process inspection.

Market Restraints

- Pricing Pressures: Pricing pressures from customers and competitors pose challenges for air plug gage manufacturers in maintaining profitability and market share while offering competitive pricing and value-added services.

- Competition from Alternative Methods: Competition from alternative measurement methods such as coordinate measuring machines (CMMs), optical measurement systems, and handheld gauges with digital readouts presents a threat to the market share of air plug gages.

- Regulatory Compliance: Compliance with industry regulations, standards, and certifications, such as ISO 9001, AS9100, and NIST traceability, adds complexity and cost to air plug gage manufacturing, distribution, and calibration processes.

- Skilled Workforce Shortage: The shortage of skilled workers with expertise in precision machining, metrology, and quality inspection poses challenges for companies in recruiting, training, and retaining qualified personnel to operate and maintain air plug gages effectively.

Market Opportunities

- Customization and Specialization: Offering customized air plug gage solutions tailored to specific customer requirements, applications, and industry standards presents opportunities for manufacturers to differentiate products and add value for customers.

- Industry 4.0 Integration: Integration with Industry 4.0 technologies such as IoT sensors, data analytics, and cloud computing enables smart manufacturing solutions, predictive maintenance, and real-time quality monitoring for air plug gages.

- Global Expansion: Expanding into new geographic markets and regions with growing manufacturing sectors, infrastructure projects, and industrialization efforts offers opportunities for air plug gage manufacturers to diversify revenue streams and tap into emerging markets.

- After-Sales Services: Providing comprehensive after-sales services such as calibration, maintenance, repair, and training enhances customer satisfaction, loyalty, and long-term partnerships while generating additional revenue streams for manufacturers.

Market Dynamics

The air plug gages market operates in a dynamic environment influenced by factors such as technological advancements, industry trends, regulatory changes, and competitive pressures. Market dynamics such as product innovation, pricing strategies, distribution channels, and customer preferences shape market competitiveness and growth prospects, requiring companies to adapt and innovate to stay ahead.

Regional Analysis

The air plug gages market exhibits regional variations driven by factors such as industrialization levels, economic conditions, manufacturing sectors, and regulatory frameworks. Key regions such as North America, Europe, Asia-Pacific, Latin America, and the Middle East and Africa offer diverse market opportunities and challenges for air plug gage manufacturers, distributors, and end-users.

- North America: The North American market for air plug gages is driven by factors such as advanced manufacturing capabilities, stringent quality standards, and high demand from industries such as automotive, aerospace, and medical devices.

- Europe: Europe is a significant market for air plug gages, characterized by a strong manufacturing base, emphasis on precision engineering, and regulatory requirements for quality control and metrology in industries such as automotive, aerospace, and electronics.

- Asia-Pacific: The Asia-Pacific region presents growth opportunities for air plug gage manufacturers due to factors such as rapid industrialization, expanding manufacturing sectors, infrastructure investments, and increasing adoption of quality control measures in countries such as China, Japan, and India.

- Latin America: Latin America offers potential for market expansion in industries such as automotive, electronics, and consumer goods, driven by economic growth, industrial modernization, and demand for high-quality products in countries like Brazil, Mexico, and Argentina.

- Middle East and Africa: The Middle East and Africa region present opportunities for air plug gage manufacturers in sectors such as oil and gas, construction, and manufacturing, driven by infrastructure projects, industrial diversification, and economic development efforts.

Competitive Landscape

Leading Companies in the Air Plug Gages Market:

- Vermont Gage LLC (Mitutoyo Corporation)

- Meyer Gage Company, Inc.

- Mahr Inc.

- Sunnen Products Company

- Insize Co., Ltd.

- Deltronic

- Western Gage Corporation

- Bowers Group

- Marposs S.p.A.

- Emuge-Franken

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The air plug gages market can be segmented based on various factors such as:

- Type: Air ring plug gages, air plug gage sets, custom air plug gages.

- Size Range: Small diameter, medium diameter, large diameter.

- End-Use Industry: Automotive, aerospace, electronics, medical devices, manufacturing.

- Region: North America, Europe, Asia-Pacific, Latin America, Middle East & Africa.

Segmentation provides insights into market trends, customer preferences, and growth opportunities, enabling companies to develop targeted marketing strategies, product offerings, and sales initiatives to maximize market share and profitability.

Category-wise Insights

- Automotive Industry: Air plug gages are extensively used in the automotive industry for quality control and dimensional verification of engine components, transmission parts, brake systems, and chassis components to ensure precise fit and functionality.

- Aerospace Industry: The aerospace industry relies on air plug gages for measuring critical dimensions of aircraft engine components, landing gear parts, structural assemblies, and hydraulic systems to meet stringent safety and performance requirements.

- Electronics Manufacturing: Air plug gages play a crucial role in the electronics manufacturing industry for inspecting precision components such as connectors, terminals, printed circuit boards (PCBs), and semiconductor devices with high accuracy and repeatability.

- Medical Device Manufacturing: The medical device manufacturing industry utilizes air plug gages for measuring the internal dimensions of surgical instruments, implantable devices, medical implants, and diagnostic equipment to ensure compliance with regulatory standards and patient safety.

Key Benefits for Industry Participants and Stakeholders

The air plug gages market offers several benefits for industry participants and stakeholders, including:

- High Accuracy and Repeatability: Air plug gages provide accurate and repeatable measurements with minimal operator influence, ensuring reliable quality control and dimensional verification in manufacturing processes.

- Efficient Inspection Process: Air plug gages enable fast and efficient inspection of internal dimensions, hole depths, and cylindrical features without surface contact, reducing inspection time and increasing productivity in production environments.

- Versatility and Flexibility: Air plug gages are versatile and adaptable to various part geometries, sizes, and materials, offering flexibility for measuring a wide range of components in diverse industries and applications.

- Cost-Effective Solution: Air plug gages offer a cost-effective measurement solution compared to alternative methods such as coordinate measuring machines (CMMs) or manual gauges, providing significant savings in time, labor, and resources.

SWOT Analysis

A SWOT analysis of the air plug gages market provides insights into its strengths, weaknesses, opportunities, and threats:

- Strengths:

- High accuracy and repeatability.

- Non-contact measurement capabilities.

- Versatility and adaptability to various applications.

- Integration with automation systems and Industry 4.0 technologies.

- Weaknesses:

- Dependence on compressed air supply and pressure regulation.

- Limited size range and measurement capabilities for certain applications.

- Initial setup and calibration requirements for accurate measurement.

- Opportunities:

- Customization and specialization for specific industry requirements.

- Integration with digital technologies for smart manufacturing solutions.

- Expansion into emerging markets and geographic regions with growing manufacturing sectors.

- Threats:

- Competition from alternative measurement methods and technologies.

- Pricing pressures from customers and competitors.

- Regulatory compliance and certification requirements.

- Economic downturns and market uncertainties affecting customer demand.

Market Key Trends

- Digitalization and Automation: Integration with digital technologies such as IoT sensors, data analytics, and cloud computing enables real-time monitoring, predictive maintenance, and remote diagnostics for air plug gages in smart manufacturing environments.

- Miniaturization and Micro-Machining: The trend towards miniaturization and micro-machining in industries such as electronics, medical devices, and precision engineering drives demand for high-precision measurement tools like air plug gages with smaller diameters and tighter tolerances.

- Industry 4.0 Integration: The adoption of Industry 4.0 principles and technologies such as artificial intelligence (AI), machine learning (ML), and robotics in manufacturing processes creates opportunities for air plug gages to improve efficiency, quality, and productivity.

- Remote Monitoring and Control: Remote monitoring and control capabilities enable operators to monitor air plug gage performance, conduct diagnostics, and adjust settings remotely, reducing downtime, optimizing resources, and improving overall equipment effectiveness (OEE).

Covid-19 Impact

The Covid-19 pandemic had a mixed impact on the air plug gages market, with disruptions in supply chains, production schedules, and customer demand in some industries, while highlighting the importance of quality control, automation, and digitalization in others.

- Supply Chain Disruptions: Disruptions in supply chains, logistics, and manufacturing operations due to lockdowns, travel restrictions, and border closures affected air plug gage manufacturers and distributors, leading to delays in production and order fulfillment.

- Shift in Customer Demand: Changes in customer demand patterns and priorities due to the pandemic, such as increased demand for medical devices, personal protective equipment (PPE), and electronic devices, influenced market dynamics and product requirements for air plug gages.

- Adoption of Remote Solutions: The pandemic accelerated the adoption of remote monitoring, virtual collaboration, and digital solutions for air plug gages, enabling manufacturers and end-users to maintain operations, conduct inspections, and ensure quality control remotely.

- Focus on Safety and Compliance: Ensuring safety, hygiene, and compliance with regulatory standards became paramount during the pandemic, driving demand for air plug gages with non-contact measurement capabilities, remote monitoring features, and compliance certifications.

Key Industry Developments

- Product Innovation: Continued innovations in air plug gage design, materials, and manufacturing processes enhance performance, reliability, and ease of use, meeting customer requirements for precision measurement and quality assurance.

- Smart Manufacturing Solutions: Integration with smart manufacturing solutions such as digital twin technology, augmented reality (AR), and predictive analytics enables real-time data insights, predictive maintenance, and process optimization for air plug gages.

- Quality Management Systems: Implementation of quality management systems (QMS) such as ISO 9001, AS9100, and IATF 16949 drives standardization, traceability, and continuous improvement in air plug gage manufacturing, calibration, and quality control processes.

- Industry Collaboration: Collaboration among air plug gage manufacturers, distributors, end-users, and regulatory authorities fosters knowledge sharing, best practices, and industry standards to address market challenges and opportunities effectively.

Analyst Suggestions

- Invest in Digitalization: Air plug gage manufacturers should invest in digitalization and automation technologies to enhance product capabilities, connectivity, and value-added services for customers in smart manufacturing environments.

- Expand Market Reach: Expanding into new geographic markets, industries, and applications presents growth opportunities for air plug gage manufacturers to diversify revenue streams, mitigate risks, and capitalize on emerging trends.

- Enhance Customer Engagement: Building strong customer relationships through customized solutions, responsive support, and value-added services strengthens brand loyalty, market positioning, and long-term partnerships in the air plug gages market.

- Sustain Innovation: Continuous innovation in product design, materials, and technology ensures competitiveness, differentiation, and relevance in the dynamic market landscape, driving customer satisfaction and market leadership.

Future Outlook

The future outlook for the air plug gages market is positive, driven by factors such as increasing demand for precision measurement, technological advancements, industry 4.0 integration, and global expansion opportunities. However, challenges such as pricing pressures, competition from alternative methods, and regulatory compliance require strategic planning, innovation, and collaboration to sustain growth and profitability in the market.

Conclusion

The air plug gages market plays a vital role in precision measurement, quality control, and process optimization for various industries such as automotive, aerospace, electronics, and medical devices. With increasing demand for high-precision components, stringent quality standards, and technological advancements in manufacturing processes, the market offers significant opportunities for innovation, growth, and market leadership. By focusing on customer needs, digitalization, sustainability, and collaboration, air plug gage manufacturers can navigate market challenges, capitalize on emerging trends, and achieve long-term success in the global marketplace.