444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

Market Overview

The United States Radiation-Hardened Electronics Market is a thriving sector within the country’s electronics industry. Radiation-hardened electronics refer to electronic components and systems that are designed to withstand the harmful effects of ionizing radiation. These components are crucial in applications where exposure to radiation is inevitable, such as aerospace, defense, and nuclear power plants.

Meaning

Radiation-hardened electronics are specifically engineered to operate reliably and accurately in high-radiation environments. The primary goal is to protect electronic systems from the detrimental effects of radiation, which can cause data corruption, circuit malfunction, or even complete system failure. These components are typically designed to be resistant to ionizing radiation, including both total ionizing dose (TID) and single-event effects (SEE) such as single-event upsets (SEUs) and single-event latch-ups (SELs).

Executive Summary

The United States Radiation-Hardened Electronics Market has been witnessing steady growth due to the increasing demand for radiation-resistant electronic components in critical applications. This market is primarily driven by the aerospace and defense sectors, which require reliable electronics capable of operating in extreme environments. The market offers a wide range of radiation-hardened electronic components, including microprocessors, field-programmable gate arrays (FPGAs), memories, and power management devices.

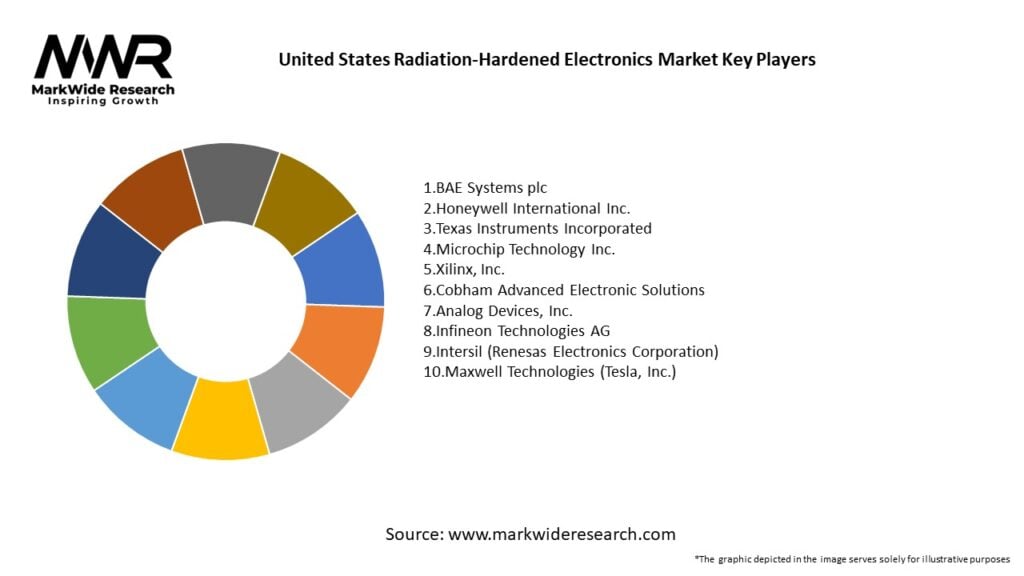

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Several factors are driving the growth of the United States Radiation-Hardened Electronics Market:

Market Restraints

Despite the positive outlook, the United States Radiation-Hardened Electronics Market faces certain challenges:

Market Opportunities

The United States Radiation-Hardened Electronics Market presents several opportunities for growth and innovation:

Market Dynamics

The United States Radiation-Hardened Electronics Market is influenced by various dynamics, including technological advancements, regulatory frameworks, and industry collaborations. These factors shape the market landscape and impact its growth trajectory.

Technological advancements play a crucial role in driving market growth. Ongoing research and development efforts focus on improving the performance and reliability of radiation-hardened electronics. Innovations in materials, circuit designs, and fabrication techniques enable the production of more robust components capable of withstanding higher radiation levels.

Regulatory frameworks and industry standards also influence the market. Government agencies and industry associations set guidelines and requirements for radiation-hardened electronics used in critical applications. Compliance with these standards ensures the safety and reliability of electronic systems in radiation-intensive environments.

Collaborations between market players, research institutions, and government agencies foster innovation and knowledge sharing. Joint initiatives enable the development of new radiation-hardening techniques, testing methodologies, and product certifications. These collaborations enhance the market’s growth potential and facilitate the adoption of radiation-hardened electronics across industries.

Regional Analysis

The United States Radiation-Hardened Electronics Market exhibits a strong regional presence, with key market players located in various states. Major regions contributing to the market growth include:

Other states, such as Florida, Arizona, and Virginia, also contribute to the market due to their aerospace and defense sectors.

Competitive Landscape

Leading companies in the United States Radiation-Hardened Electronics Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

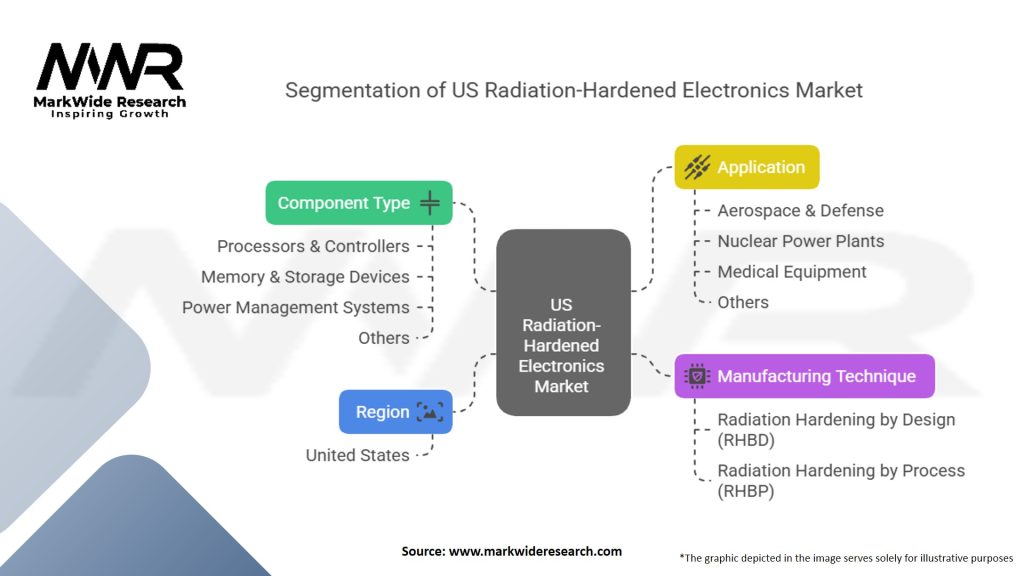

Segmentation

The United States Radiation-Hardened Electronics Market can be segmented based on the following criteria:

Segmenting the market allows for a better understanding of the specific needs and demands within each category, enabling market players to tailor their offerings accordingly.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

The United States Radiation-Hardened Electronics Market offers several benefits for industry participants and stakeholders:

SWOT Analysis

A SWOT (Strengths, Weaknesses, Opportunities, Threats) analysis of the United States Radiation-Hardened Electronics Market provides insights into the internal and external factors that impact the market’s growth and competitiveness:

Strengths:

Weaknesses:

Opportunities:

Threats:

Understanding these factors allows market participants to capitalize on strengths, address weaknesses, seize opportunities, and mitigate potential threats.

Market Key Trends

The United States Radiation-Hardened Electronics Market is characterized by several key trends:

Covid-19 Impact

The Covid-19 pandemic had a mixed impact on the United States Radiation-Hardened Electronics Market. While certain sectors, such as aerospace and defense, experienced disruptions due to supply chain disruptions and project delays, the market as a whole remained resilient.

During the pandemic, the aerospace industry faced challenges with reduced air travel and delayed projects. This led to a temporary slowdown in the demand for radiation-hardened electronics used in aerospace applications. However, the industry has started to recover as air travel gradually resumes and the backlog of delayed projects is addressed.

The defense sector demonstrated more resilience, with governments prioritizing defense spending and critical infrastructure projects. The demand for radiation-hardened electronics in defense applications remained steady, supporting the market’s stability.

Overall, the United States Radiation-Hardened Electronics Market weathered the pandemic’s impact and is expected to rebound as the global economy recovers and industry activities resume normalcy.

Key Industry Developments

The United States Radiation-Hardened Electronics Market has witnessed significant industry developments in recent years:

Analyst Suggestions

Based on the analysis of the United States Radiation-Hardened Electronics Market, analysts offer the following suggestions:

Future Outlook

The future of the United States Radiation-Hardened Electronics Market looks promising. The increasing demand for reliable and resilient electronic components in critical applications, such as aerospace, defense, and nuclear power, is expected to drive market growth. Technological advancements, collaborations, and the exploration of new application areas will further propel the market forward.

The market will continue to witness advancements in radiation-hardening techniques, enabling the development of more robust and efficient components. The miniaturization and integration of radiation-hardened electronics will cater to the demand for compact and space-constrained applications.

While challenges such as manufacturing costs and limited commercial applications persist, industry players are likely to find innovative solutions and explore new avenues for growth. Continued investment in research and development, strategic collaborations, and a focus on cost optimization will be key factors shaping the future of the United States Radiation-Hardened Electronics Market.

Conclusion

The United States Radiation-Hardened Electronics Market is a thriving sector driven by the demand for reliable electronic components in high-radiation environments. The aerospace, defense, and nuclear power industries are the primary drivers of market growth. Technological advancements, collaborations, and the exploration of new applications present significant opportunities.

Although challenges exist, including manufacturing costs and limited commercial applications, the market is expected to grow. Continued investment in research and development, strategic partnerships, and cost optimization will shape the future of the market. Overall, the United States Radiation-Hardened Electronics Market holds great potential for industry participants and stakeholders, contributing to technological advancements and offering resilient solutions for critical applications.

What are radiation-hardened electronics in the context of the United States Radiation-Hardened Electronics Market?

Radiation-hardened electronics are specially designed components that can withstand high levels of radiation, making them essential for applications in space, nuclear facilities, and military environments. These electronics are crucial for ensuring reliability and performance in harsh conditions.

Which companies are key players in the United States Radiation-Hardened Electronics Market?

Key players in the United States Radiation-Hardened Electronics Market include companies like Texas Instruments, BAE Systems, and Microsemi, which specialize in developing radiation-hardened components for aerospace and defense applications, among others.

What are the main drivers of growth in the United States Radiation-Hardened Electronics Market?

The growth of the United States Radiation-Hardened Electronics Market is driven by increasing demand for reliable electronics in space exploration, advancements in satellite technology, and the need for robust systems in military applications.

What challenges does the United States Radiation-Hardened Electronics Market face?

Challenges in the United States Radiation-Hardened Electronics Market include the high cost of development and production, the complexity of designing components that can withstand extreme conditions, and competition from commercial off-the-shelf electronics.

What future opportunities exist in the United States Radiation-Hardened Electronics Market?

Future opportunities in the United States Radiation-Hardened Electronics Market include the growing demand for satellite constellations, advancements in radiation-hardened technology, and increased investment in space exploration initiatives.

What trends are shaping the United States Radiation-Hardened Electronics Market?

Trends in the United States Radiation-Hardened Electronics Market include the integration of advanced materials for better radiation resistance, the miniaturization of components, and the increasing use of artificial intelligence in electronic systems for enhanced performance.

United States Radiation-Hardened Electronics Market

| Segmentation | Details |

|---|---|

| Component Type | Processors & Controllers, Memory & Storage Devices, Power Management Systems, Others |

| Manufacturing Technique | Radiation Hardening by Design (RHBD), Radiation Hardening by Process (RHBP) |

| Application | Aerospace & Defense, Nuclear Power Plants, Medical Equipment, Others |

| Region | United States |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the United States Radiation-Hardened Electronics Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at