The dynamics of the Rubber Vulcanizer Market are influenced by various factors:

- Consumer Preferences: Shifts in consumer preferences towards durable and high-quality rubber products are shaping market trends.

- Technological Advancements: Continuous innovations in vulcanization technology are driving market growth and enhancing product offerings.

- Regulatory Environment: Compliance with local and international regulations is critical for market participants and can impact product development.

Regional Analysis

The market for rubber vulcanizers varies across different regions, influenced by local industrial activities, regulations, and economic conditions:

- North America: The largest market for rubber vulcanizers, driven by strong demand from the automotive and construction sectors.

- Europe: Rapid growth due to stringent regulations and an emphasis on quality control in manufacturing processes.

- Asia-Pacific: An emerging market with substantial growth potential driven by expanding industrial activities and increasing demand for rubber products.

- Latin America: Gradual growth as countries invest in infrastructure and manufacturing, creating demand for rubber vulcanization solutions.

- Middle East and Africa: Increasing demand for rubber products in construction and manufacturing sectors is driving market growth in this region.

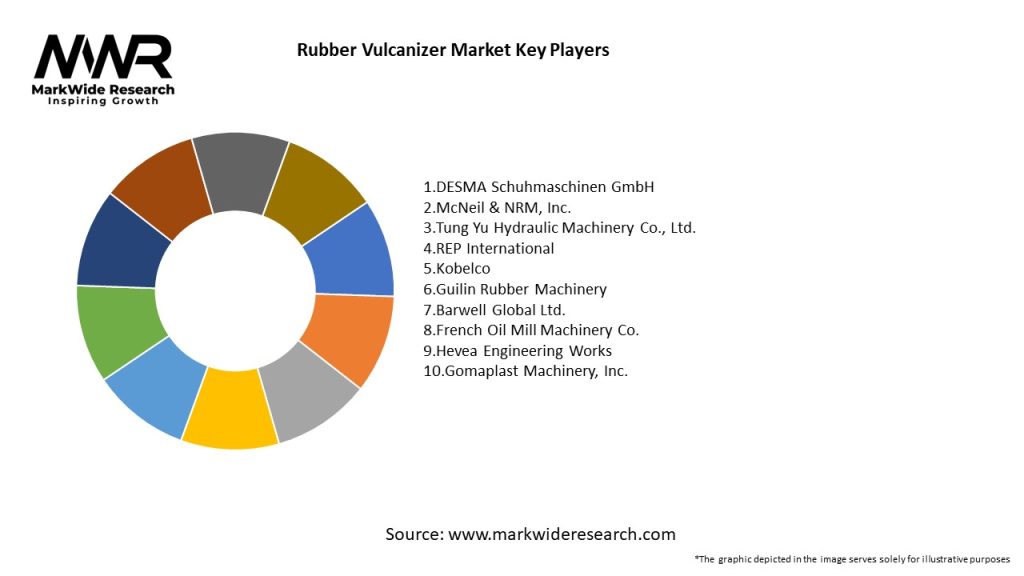

Competitive Landscape

Leading Companies in Rubber Vulcanizer Market:

- DESMA Schuhmaschinen GmbH

- McNeil & NRM, Inc.

- Tung Yu Hydraulic Machinery Co., Ltd.

- REP International

- Kobelco

- Guilin Rubber Machinery

- Barwell Global Ltd.

- French Oil Mill Machinery Co.

- Hevea Engineering Works

- Gomaplast Machinery, Inc.

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The Rubber Vulcanizer Market can be segmented based on:

- Type of Vulcanizer:

- Batch Vulcanizers: Used for processing rubber in batches, suitable for small-scale production.

- Continuous Vulcanizers: Designed for continuous production processes, ideal for high-volume applications.

- Press Vulcanizers: Utilized for molding and vulcanizing rubber products in various shapes and sizes.

- Application:

- Automotive: Vulcanizers used in the production of automotive rubber components, such as tires, seals, and gaskets.

- Industrial: Used in the manufacturing of industrial rubber products, including conveyor belts and hoses.

- Consumer Goods: Vulcanizers employed in the production of rubber goods for consumer applications.

- End-user:

- Manufacturers: Companies involved in producing rubber products for various applications.

- Research Institutions: Organizations focused on research and development in rubber technology.

- Geography:

- North America: Leading region in market share.

- Europe: Rapid growth driven by regulatory support and industrial advancements.

- Asia-Pacific: Significant potential for expansion in emerging markets.

Category-wise Insights

- Automotive: The largest segment, favored for its critical role in the production of automotive rubber components.

- Industrial: Gaining traction as industries focus on ensuring product quality and durability.

Key Benefits for Industry Participants and Stakeholders

- Revenue Growth: The increasing demand for rubber vulcanizers provides significant revenue opportunities for manufacturers and suppliers.

- Brand Recognition and Loyalty: Companies focusing on quality and innovation can build strong brand recognition and customer loyalty.

- Market Differentiation: Investing in advanced technologies and unique product features can help companies stand out in a competitive marketplace.

- Collaboration Opportunities: Partnerships with manufacturers and research institutions can enhance market presence and facilitate product adoption.

- Sustainable Practices: Emphasizing eco-friendly practices in product development can align with consumer preferences for sustainability.

SWOT Analysis

Strengths:

- Growing Demand for Rubber Products: Increasing use of rubber in various industries drives the need for efficient vulcanization processes.

- Diverse Applications: Wide-ranging applications of rubber vulcanizers cater to various industry needs.

Weaknesses:

- High Initial Investment: The significant capital required for advanced vulcanization equipment may deter some potential buyers.

- Limited Awareness: Some stakeholders may lack awareness of the benefits of modern vulcanization technologies compared to traditional methods.

Opportunities:

- Emerging Markets: Growth in industrial sectors in emerging economies presents opportunities for market expansion.

- Focus on Innovation: Investing in research and development can lead to innovations in rubber vulcanization technology.

Threats:

- Economic Uncertainty: Economic fluctuations may impact industrial spending on rubber processing solutions.

- Intense Competition: The presence of numerous competitors can lead to pricing pressures and reduced profit margins.

Market Key Trends

- Integration of Smart Technology: The use of automation and smart technologies in vulcanization processes is becoming increasingly popular.

- Focus on Sustainability: Increasing consumer awareness of environmental issues is driving demand for eco-friendly rubber processing solutions.

- Customization and Personalization: Growing interest in tailored solutions for specific industry applications is shaping market offerings.

- Increased Investment in R&D: The focus on research and development is driving innovation in rubber vulcanization technologies.

- Urbanization and Industrial Growth: The rapid pace of urbanization and industrial growth is driving the demand for quality control solutions in rubber manufacturing.

Covid-19 Impact

The Covid-19 pandemic has influenced the Rubber Vulcanizer Market in various ways:

- Temporary Disruption of Services: The pandemic caused disruptions in manufacturing operations, impacting the demand for vulcanization solutions.

- Increased Focus on Quality Assurance: Heightened awareness of quality and safety during the pandemic has driven demand for reliable rubber processing solutions.

- Shifts in Investment Priorities: Changes in funding priorities due to the pandemic may affect investments in rubber manufacturing technologies.

- Growth of Remote Solutions: The rise of remote solutions for monitoring and quality control may impact traditional manufacturing demand.

Key Industry Developments

- Product Innovations: Major manufacturers are launching new rubber vulcanization models with enhanced features and capabilities.

- Collaborative Efforts: Companies are forming partnerships with industry players to promote the adoption of rubber vulcanizers in manufacturing.

- Focus on Digital Solutions: The integration of digital solutions for monitoring and optimizing vulcanization processes is gaining traction.

- Sustainability Initiatives: An increasing number of manufacturers are prioritizing sustainability in their production processes and product offerings.

Analyst Suggestions

- Invest in R&D: Companies should prioritize research and development to innovate and enhance the performance of rubber vulcanizers.

- Enhance Consumer Education: Providing educational resources about the benefits and applications of rubber vulcanization can increase awareness and engagement.

- Collaborate with Stakeholders: Building partnerships with manufacturers and research institutions can strengthen market presence and facilitate product adoption.

- Focus on Customization: Offering tailored rubber vulcanization solutions that meet specific industry needs can enhance customer satisfaction.

- Strengthen Supply Chains: Developing robust supply chain strategies can help mitigate risks associated with production disruptions and material availability.

Future Outlook

The Rubber Vulcanizer Market is expected to continue its growth trajectory in the coming years, driven by increasing demand for rubber products, advancements in vulcanization technology, and a growing focus on quality assurance. As manufacturers focus on innovation, collaboration, and sustainability, the market is set to evolve, providing significant opportunities for stakeholders and participants in the rubber vulcanization sector.

Conclusion