- Environmental Sustainability: The market is witnessing a shift towards sustainable insulation solutions made from recycled materials, bio-based composites, and low-emission products to reduce environmental impact and promote eco-friendly practices.

- Retrofit and Maintenance: Retrofitting existing industrial equipment with heat-insulation boards and conducting regular maintenance and inspection services are driving market demand as companies seek to improve energy efficiency, prolong equipment lifespan, and reduce operating costs.

Market Drivers

- Energy Conservation Initiatives: Government initiatives, incentives, and regulations promoting energy conservation and sustainable practices are driving the adoption of heat-insulation boards in industrial facilities to reduce energy consumption and greenhouse gas emissions.

- Cost Savings and ROI: The use of heat-insulation boards results in significant cost savings over time by lowering energy bills, improving equipment efficiency, reducing maintenance costs, and extending the lifespan of industrial assets.

- Thermal Performance Requirements: Industries such as petrochemicals, food processing, pharmaceuticals, and automotive manufacturing require precise temperature control and insulation to maintain product integrity, quality, and safety standards, driving demand for high-performance insulation solutions.

- Environmental Regulations: Stricter environmental regulations regarding emissions, energy efficiency, and sustainability are compelling industries to invest in thermal insulation solutions to comply with standards, reduce environmental impact, and enhance corporate social responsibility (CSR).

Market Restraints

- Initial Investment Costs: The upfront costs of purchasing and installing heat-insulation boards can be a barrier for some companies, especially small and medium-sized enterprises (SMEs), despite long-term cost savings and benefits.

- Technical Challenges: Selecting the right insulation materials, designing customized solutions, ensuring proper installation, and addressing compatibility issues with existing equipment can pose technical challenges for end-users and suppliers.

- Maintenance and Replacement: Over time, insulation materials may degrade, requiring regular maintenance, inspections, and potential replacement, which can add to operational costs and downtime for industrial facilities.

- Market Fragmentation: The heat-insulation boards market is characterized by the presence of numerous suppliers, brands, and product variants, leading to market fragmentation, price competition, and challenges in differentiation and brand positioning.

Market Opportunities

- Green Building Trends: The growing trend towards green buildings, LEED certification, sustainable construction practices, and energy-efficient designs presents opportunities for heat-insulation board manufacturers to collaborate with architects, builders, and developers in the construction sector.

- Infrastructure Development: Investments in infrastructure projects, including smart cities, transportation networks, renewable energy installations, and industrial parks, create opportunities for heat-insulation board suppliers to provide insulation solutions for new construction and retrofit projects.

- Technological Innovations: Research and development (R&D) initiatives focusing on innovative insulation materials, nanotechnology, smart insulation systems, and digital monitoring tools offer opportunities for market players to differentiate their products and meet evolving customer needs.

- Energy Transition: The global shift towards renewable energy sources, electrification of industries, and decarbonization efforts present opportunities for heat-insulation board suppliers to support energy transition initiatives by providing thermal insulation solutions for renewable energy infrastructure, electric vehicles, and energy storage systems.

Market Dynamics

The Heat-Insulation Boards for Industrial Equipment Market operates in a dynamic environment shaped by technological advancements, regulatory developments, market trends, and customer preferences. Key dynamics driving market growth and evolution include:

- Technological Advancements: Continued R&D efforts to develop advanced insulation materials, sustainable solutions, smart insulation systems, and digital tools for monitoring and optimizing thermal performance.

- Regulatory Landscape: Changes in energy efficiency standards, environmental regulations, fire safety codes, and building codes influence market demand, product requirements, and industry practices.

- Competitive Landscape: Intense competition among heat-insulation board suppliers, manufacturers, and distributors drives innovation, product differentiation, pricing strategies, and market consolidation activities.

- Customer Preferences: Increasing awareness among customers about energy conservation, environmental sustainability, safety standards, and product performance influences purchasing decisions, product specifications, and supplier relationships.

Regional Analysis

The Heat-Insulation Boards for Industrial Equipment Market exhibits regional variations in demand, market dynamics, regulatory frameworks, and industry trends:

- North America: The region is characterized by stringent energy efficiency regulations, green building initiatives, technological innovation hubs, and a focus on sustainable practices, driving market growth for heat-insulation boards in industries such as manufacturing, construction, and energy.

- Europe: European countries prioritize energy conservation, sustainable development, circular economy principles, and green building certifications, creating a favorable market environment for heat-insulation board suppliers and eco-friendly insulation solutions.

- Asia Pacific: Rapid industrialization, urbanization, infrastructure investments, and government initiatives promoting energy efficiency and environmental protection drive market demand for heat-insulation boards in sectors like construction, manufacturing, automotive, and power generation.

- Latin America: Growing infrastructure projects, renewable energy investments, industrial expansions, and regulatory measures for energy efficiency and emissions reduction offer opportunities for heat-insulation board suppliers in the region.

- Middle East and Africa: The region’s focus on sustainable development, diversification of economies, infrastructure investments, and energy transition initiatives drive market growth for heat-insulation boards in sectors such as oil and gas, construction, and manufacturing.

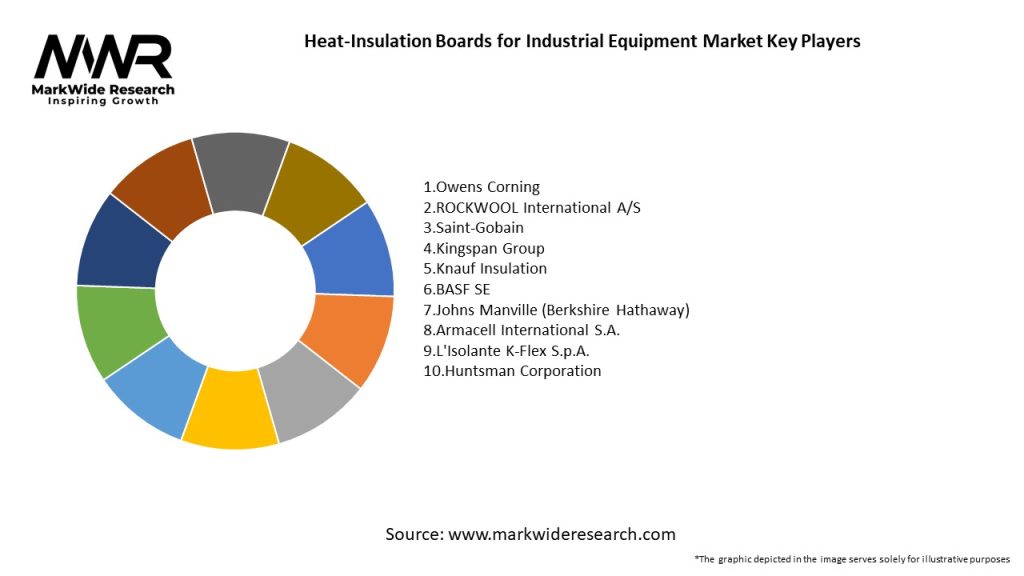

Competitive Landscape

Leading Companies in the Heat-Insulation Boards for Industrial Equipment Market:

- Owens Corning

- ROCKWOOL International A/S

- Saint-Gobain

- Kingspan Group

- Knauf Insulation

- BASF SE

- Johns Manville (Berkshire Hathaway)

- Armacell International S.A.

- L’Isolante K-Flex S.p.A.

- Huntsman Corporation

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The Heat-Insulation Boards for Industrial Equipment Market can be segmented based on various factors:

- Material Type: Fiberglass, mineral wool, foam plastics, aerogels, and other specialized materials used in heat-insulation boards.

- End-Use Industry: Construction, manufacturing, energy, automotive, aerospace, marine, and other industrial sectors requiring thermal insulation solutions.

- Application: Boilers, furnaces, pipelines, HVAC systems, storage tanks, ovens, and other equipment requiring thermal management and energy conservation.

- Geographic Region: North America, Europe, Asia Pacific, Latin America, Middle East, and Africa, each with unique market characteristics and demand drivers.

Segmentation provides a deeper understanding of market trends, customer preferences, product requirements, and competitive dynamics, enabling suppliers to tailor their strategies, offerings, and marketing efforts to specific market segments and target audiences.

Category-wise Insight

- Construction Sector: Heat-insulation boards play a crucial role in commercial buildings, residential complexes, industrial facilities, and infrastructure projects by providing thermal insulation, energy efficiency, fire protection, and acoustic performance.

- Manufacturing Industry: Industrial equipment, machinery, process piping, and production facilities benefit from heat-insulation boards to optimize operating temperatures, reduce heat loss, improve process efficiency, and comply with safety regulations.

- Energy Sector: Power plants, renewable energy installations, oil refineries, and petrochemical plants use heat-insulation boards to insulate equipment, storage tanks, pipelines, and structures, ensuring thermal stability, energy conservation, and operational reliability.

- Automotive Applications: Heat-insulation boards are used in automotive manufacturing for thermal management, noise reduction, vibration damping, and fire protection in vehicles, engines, exhaust systems, and battery packs.

- Aerospace and Marine: The aerospace and marine industries utilize heat-insulation boards for aircraft, spacecraft, ships, and offshore structures to maintain temperature control, protect against extreme heat or cold, and enhance safety and performance.

Key Benefits for Industry Participants and Stakeholders

- Energy Savings: Heat-insulation boards help reduce energy consumption, heating and cooling costs, carbon emissions, and environmental impact, promoting energy conservation and sustainability.

- Equipment Protection: Insulation materials protect industrial equipment, machinery, pipelines, and structures from temperature fluctuations, corrosion, wear and tear, and premature failure, extending asset lifespan and reliability.

- Safety Compliance: Fire-retardant insulation boards enhance workplace safety by reducing fire hazards, preventing thermal accidents, and ensuring compliance with fire safety regulations and standards.

- Operational Efficiency: Optimal thermal management and insulation improve equipment efficiency, process performance, production output, and overall operational efficiency in industrial facilities.

- Environmental Responsibility: Sustainable insulation solutions made from recycled materials, bio-based composites, and low-emission products support environmental responsibility, circular economy practices, and corporate sustainability goals.

SWOT Analysis

- Strengths:

- High thermal resistance and insulation performance

- Fire-retardant properties and safety compliance

- Diverse applications across industries and sectors

- Contribution to energy conservation and sustainability

- Weaknesses:

- Initial investment costs for installation and retrofitting

- Technical challenges in material selection and installation

- Maintenance requirements and lifecycle considerations

- Market fragmentation and price competition

- Opportunities:

- Green building trends and sustainable construction practices

- Infrastructure development and energy transition initiatives

- Technological innovations and smart insulation solutions

- Collaborations, partnerships, and market expansion

- Threats:

- Regulatory changes and compliance requirements

- Market competition and pricing pressures

- Economic uncertainties and industry disruptions

- Substitute materials and alternative insulation solutions

Market Key Trends

- Sustainable Insulation: Growing demand for sustainable, eco-friendly insulation materials, recycled products, bio-based composites, and low-emission solutions to support green building initiatives and environmental stewardship.

- Smart Insulation Systems: Integration of digital technologies, IoT sensors, monitoring devices, and data analytics for real-time performance tracking, predictive maintenance, energy optimization, and smart building management.

- Customized Solutions: Tailored insulation solutions, customized designs, modular systems, and flexible configurations to meet specific customer requirements, project specifications, and industry standards.

- Resilient Infrastructure: Emphasis on resilient infrastructure, disaster resilience, climate resilience, and adaptive strategies using insulation materials to mitigate risks, enhance safety, and withstand extreme weather events.

Covid-19 Impact

The Covid-19 pandemic had mixed impacts on the Heat-Insulation Boards for Industrial Equipment Market:

- Supply Chain Disruptions: Initial disruptions in supply chains, logistics, and material availability due to lockdowns, travel restrictions, and labor shortages impacted production, distribution, and project timelines.

- Demand Fluctuations: Shifts in demand patterns, project delays, and uncertainty in construction, manufacturing, and infrastructure projects influenced market demand for insulation materials, with some sectors experiencing slowdowns and others adapting to new requirements.

- Remote Work Trends: Remote work, digitalization, and virtual collaboration trends accelerated during the pandemic, leading to increased adoption of digital tools, online platforms, and remote monitoring solutions for project management, customer engagement, and technical support.

- Resilience and Adaptation: Resilience planning, risk management, and business continuity strategies helped industry participants navigate challenges, diversify supply chains, enhance operational resilience, and adapt to changing market conditions.

Key Industry Developments

- Innovations in Materials: Development of advanced insulation materials, next-generation composites, nano-coatings, and smart insulation systems with enhanced thermal performance, durability, fire resistance, and sustainability features.

- Digital Transformation: Adoption of digital technologies, IoT sensors, cloud platforms, data analytics, and AI algorithms for real-time monitoring, predictive maintenance, energy optimization, and remote management of insulation systems.

- Circular Economy Initiatives: Emphasis on circular economy principles, recycling programs, waste reduction, and closed-loop manufacturing processes to minimize environmental impact, promote resource efficiency, and support sustainable practices.

- Industry Collaboration: Collaborative initiatives, industry partnerships, knowledge sharing platforms, and stakeholder engagements to address common challenges, foster innovation, drive standards development, and promote best practices in the insulation sector.

Analyst Suggestions

- Embrace Innovation: Invest in R&D, innovation labs, and technology partnerships to develop cutting-edge insulation solutions, smart systems, digital tools, and sustainable materials that address market trends and customer needs.

- Focus on Sustainability: Integrate sustainability into product design, manufacturing processes, supply chains, and corporate strategies to reduce environmental footprint, promote circularity, and enhance brand reputation as a responsible industry player.

- Enhance Digital Capabilities: Leverage digital transformation initiatives, IoT technologies, data analytics, and predictive maintenance tools to offer value-added services, remote monitoring, performance insights, and proactive customer support.

- Collaborate for Growth: Collaborate with industry stakeholders, customers, regulators, and research institutions to drive industry standards, share best practices, foster innovation ecosystems, and create synergies for market growth and resilience.

Future Outlook

The Heat-Insulation Boards for Industrial Equipment Market is poised for growth and innovation in the coming years:

- Sustainable Solutions: Increasing demand for sustainable insulation materials, eco-friendly products, energy-efficient designs, and green building certifications will drive market opportunities and regulatory compliance.

- Technological Integration: Integration of digital technologies, IoT sensors, AI algorithms, and cloud platforms into insulation systems will enhance performance monitoring, predictive maintenance, energy optimization, and user experience.

- Resilient Infrastructure: Focus on resilient infrastructure, disaster resilience, climate adaptation, and risk mitigation strategies using insulation solutions to withstand environmental challenges, extreme weather events, and operational disruptions.

- Market Expansion: Expansion into emerging markets, diversification of product portfolios, customization of solutions, and strategic partnerships will enable industry players to capitalize on growth opportunities and address evolving customer needs.

Conclusion

In conclusion, the Heat-Insulation Boards for Industrial Equipment Market is driven by energy efficiency, sustainability, technological innovation, regulatory compliance, and market dynamics across diverse industries and regions. Industry players are encouraged to invest in innovation, sustainability, digitalization, collaboration, and resilience strategies to unlock growth, differentiation, and value creation in the evolving insulation sector.