444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

Cement board tape, also known as cement board joint tape or cement board seam tape, is a specialized tape used in the installation and finishing of cementitious backer boards in tile and stone installations. Cement board tape reinforces seams, corners, and edges of cement boards, preventing cracks, leaks, and moisture intrusion in wet areas such as showers, bathrooms, and kitchen backsplashes. The cement board tape market encompasses a range of tape products designed for specific applications and installation requirements in residential, commercial, and industrial construction projects.

Meaning

Cement board tape is a fiberglass mesh tape coated with an adhesive backing used to reinforce joints, seams, and transitions between cementitious backer boards in tile and stone installations. Cement board tape provides structural integrity, crack resistance, and waterproofing protection for cement board assemblies, ensuring long-lasting durability and performance in high-moisture environments. Cement board tape is available in various widths, lengths, and thicknesses to accommodate different cement board thicknesses, tile sizes, and grout joint widths.

Executive Summary

The cement board tape market is driven by factors such as increasing demand for tile and stone installations, growing awareness of moisture management best practices, and rising adoption of cementitious backer boards in construction projects. While the market offers opportunities for growth and expansion, it also faces challenges such as competition from alternative waterproofing solutions, pricing pressures, and installation complexities. By focusing on product quality, performance testing, and installer training, cement board tape manufacturers can capitalize on emerging trends and strengthen their market position.

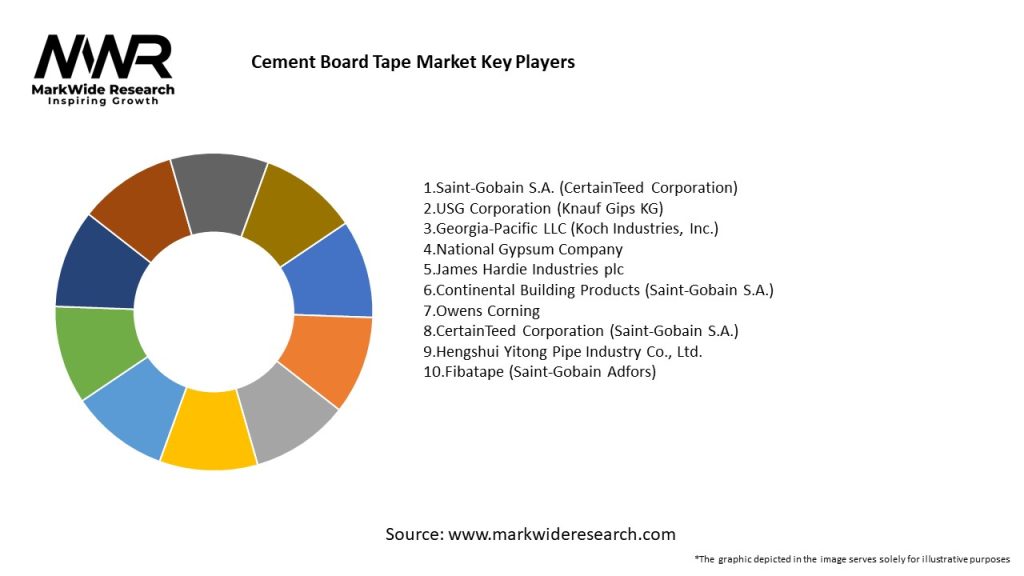

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The cement board tape market operates in a dynamic environment shaped by factors such as technological advancements, regulatory changes, competitive pressures, and consumer preferences. Market dynamics influence product development, pricing strategies, distribution channels, and competitive positioning for cement board tape manufacturers and suppliers. Understanding and adapting to market dynamics is essential for success in the cement board tape industry.

Regional Analysis

The cement board tape market exhibits regional variations in demand, market maturity, and installation practices due to factors such as climate conditions, building codes, and construction traditions. While mature markets in North America and Europe have well-established tile and stone installation industries, emerging markets in Asia Pacific, Latin America, and the Middle East present opportunities for growth and expansion through infrastructure development projects and urbanization trends.

Competitive Landscape

Leading Companies in the Cement Board Tape Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The cement board tape market can be segmented based on various factors, including tape width, length, thickness, adhesive type, and application method. Common segments include standard cement board tape, alkali-resistant cement board tape, self-adhesive cement board tape, pre-cut cement board tape, and corner reinforcement tape. Segmentation allows manufacturers to target specific customer needs, preferences, and market segments more effectively and tailor their product offerings accordingly.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Market Key Trends

Covid-19 Impact

The COVID-19 pandemic has had mixed effects on the cement board tape market, with disruptions to supply chains, construction activities, and consumer spending affecting demand and sales. While lockdowns and social distancing measures initially slowed down construction projects and home renovation activities, increased time spent indoors and heightened focus on home improvement projects led to a surge in demand for tile and stone installations, including cement board tape products, as homeowners invested in upgrading their living spaces.

Key Industry Developments

Analyst Suggestions

Future Outlook

The future outlook for the cement board tape market is positive, with continued growth expected driven by factors such as increasing demand for tile and stone installations, growing awareness of moisture management best practices, and advancements in adhesive technologies and installation systems. Innovations in product development, installer training, and sustainability initiatives will shape the market landscape, creating opportunities for cement board tape manufacturers to innovate, differentiate, and expand market presence in a dynamic and evolving industry environment.

Conclusion

In conclusion, the cement board tape market offers significant opportunities for growth and innovation, driven by factors such as increasing demand for tile and stone installations, growing awareness of moisture management requirements, and advancements in adhesive technologies and installation systems. While the market faces challenges such as competition from alternative waterproofing solutions, pricing pressures, and installation complexities, strategic focus on product quality, performance testing, and installer education can help cement board tape manufacturers navigate market dynamics and capitalize on emerging trends. By staying responsive to customer needs, regulatory requirements, and sustainability initiatives, cement board tape companies can position themselves for success and contribute to the advancement of moisture management solutions in the construction industry worldwide.

What is Cement Board Tape?

Cement Board Tape is a specialized tape used in construction to reinforce joints and seams in cement board applications. It is designed to provide a strong bond and prevent cracking, ensuring a durable finish in areas such as bathrooms and kitchens.

What are the key players in the Cement Board Tape Market?

Key players in the Cement Board Tape Market include companies like USG Corporation, James Hardie Industries, and Saint-Gobain, which are known for their innovative products and strong market presence. These companies focus on quality and performance to meet the needs of construction professionals, among others.

What are the growth factors driving the Cement Board Tape Market?

The Cement Board Tape Market is driven by the increasing demand for moisture-resistant building materials and the growth of the construction industry. Additionally, the rise in home renovation projects and the need for durable finishes in wet areas contribute to market expansion.

What challenges does the Cement Board Tape Market face?

Challenges in the Cement Board Tape Market include competition from alternative materials and the need for compliance with building regulations. Additionally, fluctuations in raw material prices can impact production costs and availability.

What opportunities exist in the Cement Board Tape Market?

Opportunities in the Cement Board Tape Market include the development of eco-friendly products and the expansion into emerging markets. As sustainability becomes a priority, manufacturers can innovate to create products that meet environmental standards.

What trends are shaping the Cement Board Tape Market?

Trends in the Cement Board Tape Market include the increasing use of advanced adhesive technologies and the growing popularity of prefabricated construction methods. These trends are enhancing the efficiency and effectiveness of cement board applications.

Cement Board Tape Market

| Segmentation Details | Description |

|---|---|

| Product Type | Fiberglass Tape, Paper Tape, Mesh Tape, Self-Adhesive Tape |

| Application | Drywall Installation, Tile Backer Board, Moisture Barrier, Joint Treatment |

| End User | Contractors, DIY Enthusiasts, Construction Companies, Homeowners |

| Distribution Channel | Online Retail, Home Improvement Stores, Wholesale Distributors, Specialty Stores |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Cement Board Tape Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at