444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

Market Overview: The India HDPE Pipes Market is a pivotal segment within the country’s infrastructure and construction industry, providing reliable and cost-effective solutions for fluid transportation and distribution. High-Density Polyethylene (HDPE) pipes are widely used in various applications such as water supply, irrigation, sewage systems, gas distribution, and industrial processes. With India’s growing population, urbanization, and industrialization, the demand for HDPE pipes continues to surge, driven by their superior properties, durability, and versatility.

Meaning: HDPE pipes are thermoplastic pipes made from high-density polyethylene resin, known for their exceptional strength, flexibility, corrosion resistance, and longevity. These pipes are manufactured through the extrusion process, resulting in seamless, leak-proof, and lightweight pipes suitable for a wide range of applications. HDPE pipes offer advantages such as chemical resistance, abrasion resistance, low thermal conductivity, and ease of installation, making them an ideal choice for various infrastructure projects in India.

Executive Summary: The India HDPE Pipes Market is witnessing robust growth propelled by factors such as government initiatives for infrastructure development, increasing investments in water management projects, and the adoption of HDPE pipes in diverse applications. Industry participants are leveraging technological advancements, strategic collaborations, and market expansion initiatives to capitalize on emerging opportunities and address challenges related to competition, pricing pressures, and regulatory compliance.

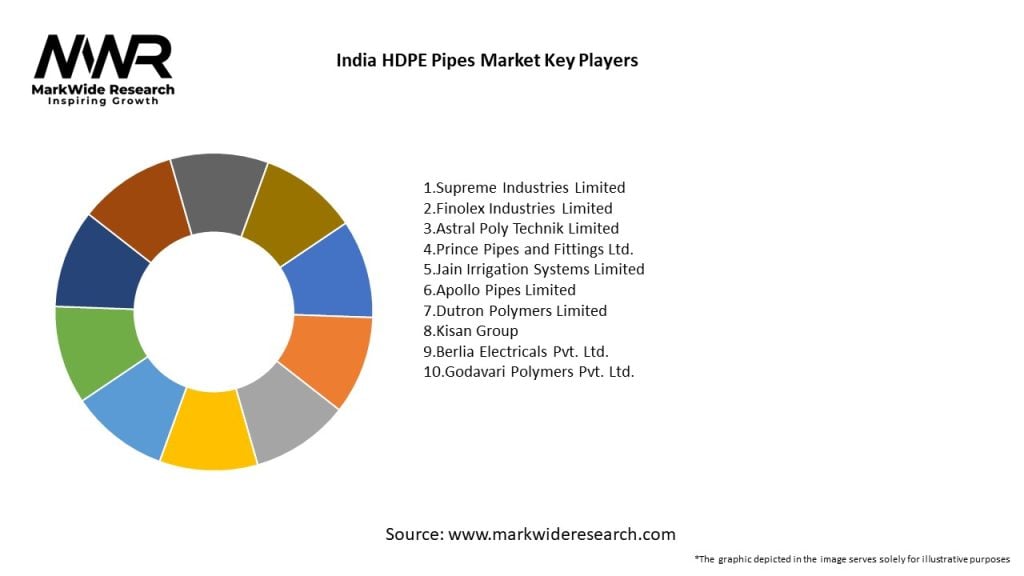

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights:

Market Drivers:

Market Restraints:

Market Opportunities:

Market Dynamics: The India HDPE Pipes Market operates within a dynamic ecosystem influenced by factors such as government policies, infrastructure investments, urbanization trends, industrial growth, technological advancements, and competitive dynamics. Market dynamics shape industry trends, customer preferences, product innovation, distribution channels, and strategic alliances, driving market growth, and evolution.

Regional Analysis: Regional variations within the India HDPE Pipes Market reflect differences in infrastructure development, water management needs, industrial activities, and regulatory environments across diverse geographic regions. An in-depth regional analysis provides insights into market opportunities, competitive landscapes, and growth potential tailored to specific regional dynamics and market realities.

Competitive Landscape:

Leading Companies in the India HDPE Pipes Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation: Segmentation within the India HDPE Pipes Market categorizes products based on parameters such as diameter, pressure rating, application, and end-user industry. Segmentation enables market participants to target specific customer segments, address unique market needs, and develop tailored product offerings and marketing strategies to maximize market penetration and revenue generation.

Category-wise Insights:

Key Benefits for Industry Participants and Stakeholders:

SWOT Analysis:

Market Key Trends:

Covid-19 Impact: The COVID-19 pandemic has influenced the India HDPE Pipes Market by disrupting supply chains, delaying project timelines, and impacting construction activities. However, the essential nature of water supply, sanitation, and infrastructure projects sustains demand for HDPE pipes, driving market resilience and adaptation to changing market dynamics.

Key Industry Developments:

Analyst Suggestions:

Future Outlook: The India HDPE Pipes Market is poised for sustained growth driven by factors such as urbanization, infrastructure investments, water management projects, and industrial expansion. While challenges such as price competition, regulatory compliance, and infrastructure constraints persist, strategic investments in technology, sustainability, market diversification, and risk management will underpin market resilience and growth prospects in the coming years.

Conclusion: In conclusion, the India HDPE Pipes Market represents a critical segment within the country’s infrastructure and construction industry, offering reliable, cost-effective, and sustainable piping solutions for diverse applications. Industry stakeholders navigate challenges and capitalize on opportunities arising from urbanization, infrastructure development, technological advancements, and market dynamics while embracing innovation, sustainability, and strategic partnerships to drive market growth and differentiation. By leveraging digital transformation, market diversification, technological innovation, and risk management strategies, industry participants can position themselves for success and contribute to India’s infrastructure development and economic growth.

What is HDPE Pipes?

HDPE Pipes, or High-Density Polyethylene Pipes, are durable plastic pipes used for various applications including water supply, irrigation, and sewage systems. They are known for their resistance to corrosion and low maintenance requirements.

What are the key players in the India HDPE Pipes Market?

Key players in the India HDPE Pipes Market include Jain Irrigation Systems, Finolex Industries, and Supreme Industries, among others. These companies are known for their extensive product ranges and strong distribution networks.

What are the growth factors driving the India HDPE Pipes Market?

The growth of the India HDPE Pipes Market is driven by increasing demand for water supply and irrigation systems, urbanization, and government initiatives for infrastructure development. Additionally, the shift towards sustainable materials is boosting market growth.

What challenges does the India HDPE Pipes Market face?

The India HDPE Pipes Market faces challenges such as fluctuating raw material prices and competition from alternative piping materials. Additionally, regulatory hurdles and quality control issues can impact market growth.

What opportunities exist in the India HDPE Pipes Market?

Opportunities in the India HDPE Pipes Market include the expansion of the agricultural sector and increasing investments in water management projects. The growing focus on smart city initiatives also presents potential for market growth.

What trends are shaping the India HDPE Pipes Market?

Trends in the India HDPE Pipes Market include the adoption of advanced manufacturing technologies and the development of eco-friendly pipes. Additionally, the increasing use of HDPE pipes in industrial applications is notable.

India HDPE Pipes Market

| Segmentation Details | Description |

|---|---|

| Product Type | Pressure Pipes, Non-Pressure Pipes, Coil Pipes, Fittings |

| Application | Water Supply, Sewage Systems, Irrigation, Industrial |

| End User | Agriculture, Construction, Municipal, Oil & Gas |

| Distribution Channel | Direct Sales, Retail, Online, Distributors |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the India HDPE Pipes Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at