444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2750

Market Overview

The Europe 3D printing construction market is at the forefront of innovation, revolutionizing traditional construction methods with advanced additive manufacturing technologies. 3D printing, also known as additive manufacturing, enables the rapid fabrication of complex architectural structures and building components using digital design data. This market is reshaping the construction industry by offering faster construction timelines, cost-effective solutions, and enhanced design flexibility.

Meaning

3D printing construction refers to the process of using additive manufacturing techniques to fabricate building structures, components, and architectural elements layer by layer. This innovative approach eliminates the need for traditional formwork and reduces material waste, leading to sustainable construction practices. By harnessing the power of digital design and automation, 3D printing enables the creation of customized, intricate building designs with unparalleled precision and efficiency.

Executive Summary

The Europe 3D printing construction market is experiencing rapid growth driven by increasing demand for sustainable, cost-effective building solutions, advancements in additive manufacturing technologies, and government initiatives promoting digitalization in the construction sector. Key market players are investing in research and development to enhance printing capabilities, expand material options, and commercialize innovative construction techniques. While challenges such as regulatory barriers and scalability issues persist, the market presents lucrative opportunities for industry stakeholders to capitalize on the transformative potential of 3D printing in construction.

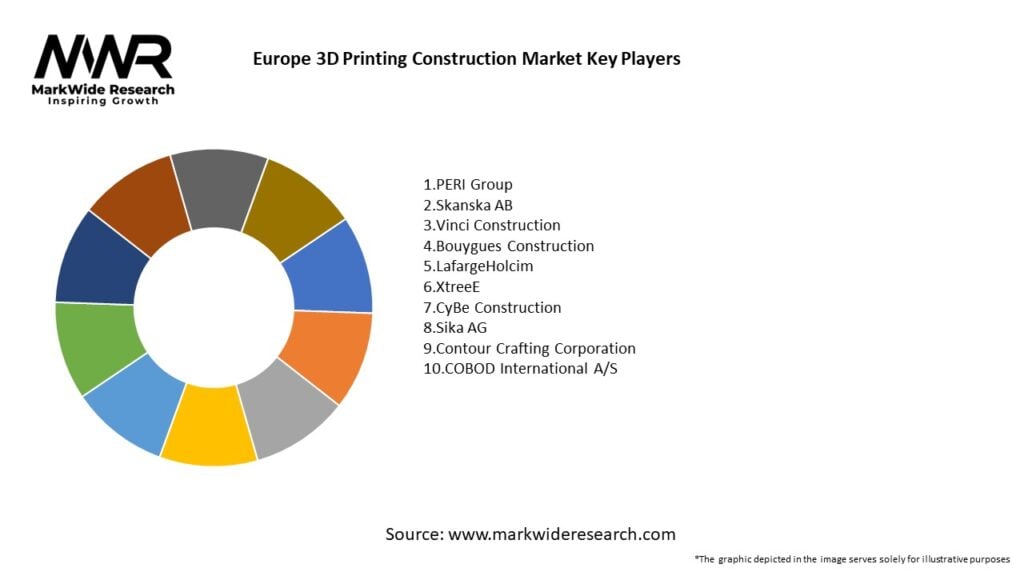

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The Europe 3D printing construction market operates in a dynamic landscape shaped by technological innovation, market demand, regulatory frameworks, and industry collaboration. Key dynamics driving market growth include advancements in printing technology, strategic partnerships between technology providers and construction firms, government support for innovation, and shifting consumer preferences towards sustainable and customizable building solutions.

Regional Analysis

The Europe 3D printing construction market exhibits regional variations in adoption rates, regulatory environments, and market maturity. Leading countries such as Germany, the Netherlands, France, and the United Kingdom are at the forefront of 3D printing research, development, and commercialization, with established ecosystems supporting innovation and industry collaboration. Emerging markets in Eastern Europe and Scandinavia present growth opportunities for technology providers and construction firms seeking to expand their presence and leverage untapped market potential.

Competitive Landscape

Leading Companies in Europe 3D Printing Construction Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The Europe 3D printing construction market can be segmented based on various factors, including printing technology, construction application, end-user industry, and geographic region. Segmentation provides insights into market trends, customer preferences, and growth opportunities tailored to specific market segments.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

A SWOT analysis provides insights into the strengths, weaknesses, opportunities, and threats facing the Europe 3D printing construction market:

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic has highlighted the importance of resilient, adaptable construction practices and accelerated the adoption of digital technologies such as 3D printing in the construction industry. While the pandemic initially disrupted supply chains and construction activities, the need for remote collaboration, off-site manufacturing, and contactless construction methods has driven demand for 3D printing solutions. As economies recover and infrastructure investment increases, the Europe 3D printing construction market is expected to rebound, fueled by government stimulus packages, infrastructure projects, and sustainable building initiatives.

Key Industry Developments

Analyst Suggestions

Future Outlook

The Europe 3D printing construction market is poised for exponential growth driven by technological innovation, market demand, and regulatory support. As 3D printing technology matures, material options expand, and industry adoption increases, the market will witness widespread integration of additive manufacturing into mainstream construction practices. With its potential to revolutionize the construction industry, 3D printing offers transformative solutions for sustainable, cost-effective, and customizable building construction, shaping the future of architecture, engineering, and urban development in Europe.

Conclusion

The Europe 3D printing construction market presents significant opportunities for innovation, growth, and sustainability in the construction industry. By harnessing the power of additive manufacturing technology, stakeholders can unlock new possibilities for design creativity, construction efficiency, and environmental responsibility. While challenges such as regulatory barriers, material limitations, and market acceptance remain, strategic investments in research, education, and collaboration can drive market expansion and establish Europe as a global leader in 3D printing construction. As the industry continues to evolve, stakeholders must adapt to changing market dynamics, embrace innovation, and seize opportunities to shape the future of construction with 3D printing technology.

Europe 3D Printing Construction Market

| Segmentation Details | Description |

|---|---|

| Technology | Fused Deposition Modeling, Stereolithography, Selective Laser Sintering, Digital Light Processing |

| Material | Concrete, Plastics, Metals, Composites |

| Application | Residential Buildings, Commercial Structures, Infrastructure Projects, Custom Components |

| End User | Construction Firms, Architects, Engineers, Developers |

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at