444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview: The Homogeneous Catalyst market is a crucial segment within the broader chemical industry, playing a pivotal role in accelerating chemical reactions and enhancing process efficiency. Homogeneous catalysts are substances that exist in the same phase as the reactants and facilitate chemical transformations without undergoing a change in their own state. This market is characterized by its diverse application across various industries, including petrochemicals, pharmaceuticals, and fine chemicals.

Meaning: Homogeneous catalysts are substances that share the same phase as the reactants in a chemical reaction. Unlike heterogeneous catalysts, which exist in a different phase, homogeneous catalysts dissolve in the reaction medium. They participate in the reaction, forming intermediates that lead to the desired products. The homogeneous nature of these catalysts allows for precise control over reaction conditions, resulting in improved selectivity and yield.

Executive Summary: The Homogeneous Catalyst market has witnessed significant growth due to the demand for more sustainable and efficient chemical processes. These catalysts offer advantages such as high activity, selectivity, and the ability to operate under mild conditions. As industries seek greener and economically viable solutions, homogeneous catalysts have gained prominence for their role in catalyzing a wide range of reactions, from polymerization to organic synthesis.

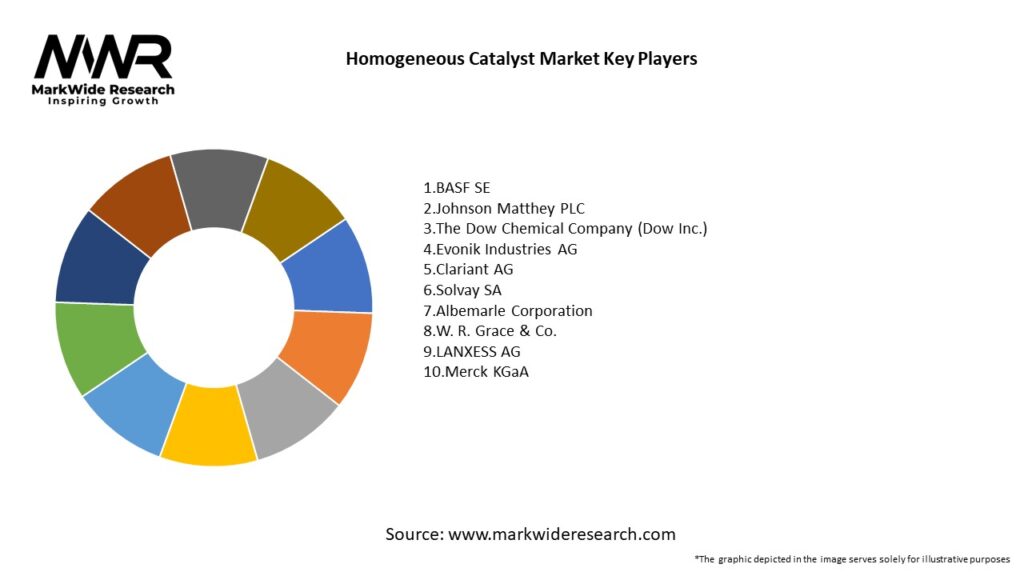

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights:

Market Drivers:

Market Restraints:

Market Opportunities:

Market Dynamics: The Homogeneous Catalyst market operates in a dynamic environment influenced by various factors, including technological advancements, market demand, regulatory landscape, and the need for sustainable solutions. The dynamic nature of the market requires continuous adaptation and innovation from industry participants.

Regional Analysis: The market for homogeneous catalysts exhibits regional variations influenced by the concentration of industries, research capabilities, and economic factors. Key regions contributing to the market include:

Competitive Landscape:

Leading Companies in Homogeneous Catalyst Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation: The Homogeneous Catalyst market can be segmented based on various factors, including:

Segmentation provides a comprehensive understanding of the market landscape, allowing businesses to tailor their strategies based on specific industry requirements and regional preferences.

Category-wise Insights:

Key Benefits for Industry Participants and Stakeholders:

SWOT Analysis: A SWOT analysis provides insights into the Homogeneous Catalyst market’s strengths, weaknesses, opportunities, and threats.

Strengths:

Weaknesses:

Opportunities:

Threats:

Understanding these factors through a SWOT analysis enables industry participants to capitalize on strengths, address weaknesses, leverage opportunities, and mitigate potential threats.

Market Key Trends:

Covid-19 Impact: The Covid-19 pandemic had varying impacts on the Homogeneous Catalyst market. While certain industries faced disruptions in supply chains and reduced production, others experienced increased demand for catalysts, particularly those used in the pharmaceutical sector for vaccine development and production.

Key Industry Developments:

Analyst Suggestions:

Future Outlook: The Homogeneous Catalyst market is poised for continuous growth, driven by factors such as sustainability initiatives, advancements in catalytic materials, and the expansion of key industries. The future outlook indicates several key trends and developments:

Conclusion: In conclusion, the Homogeneous Catalyst market stands as a key enabler of efficient and sustainable chemical processes across various industries. The market’s growth is fueled by the demand for cleaner and more environmentally friendly solutions, the emphasis on sustainable practices, and ongoing advancements in catalytic materials. Industry participants are encouraged to focus on innovation, collaboration, and the development of catalysts that align with the principles of green chemistry. As the market continues to evolve, adapting to changing consumer expectations, regulatory landscapes, and technological advancements will be essential for long-term success in the dynamic world of homogeneous catalysis. By staying at the forefront of research and development, companies can contribute to shaping a more sustainable and resilient future for the chemical industry.

Homogeneous Catalyst Market

| Segmentation Details | Description |

|---|---|

| Product Type | Metal Catalysts, Organometallic Catalysts, Acid Catalysts, Base Catalysts |

| Application | Petrochemicals, Pharmaceuticals, Polymers, Fine Chemicals |

| End Use Industry | Chemical Manufacturing, Oil & Gas, Food Processing, Environmental |

| Form | Liquid, Powder, Granular, Gel |

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at