444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

Market Overview:

The Americas Polystyrene and Acrylonitrile Butadiene Styrene (ABS) for Home Appliances Market represents a dynamic sector within the regional plastics industry, catering specifically to the manufacturing and production needs of home appliances. Polystyrene and ABS are key polymers widely used in the creation of components and casings for various home appliances, contributing to their durability and aesthetic appeal.

Meaning:

Polystyrene is a versatile and rigid polymer, while Acrylonitrile Butadiene Styrene (ABS) is known for its toughness and impact resistance. Both polymers are commonly employed in the home appliances sector for their excellent molding capabilities, heat resistance, and mechanical properties.

Executive Summary:

The Americas Polystyrene and ABS for home Appliances Market are integral to the production of durable and visually appealing components in the home appliances industry. The market’s growth is driven by the demand for reliable materials that enhance the performance and aesthetics of household devices.

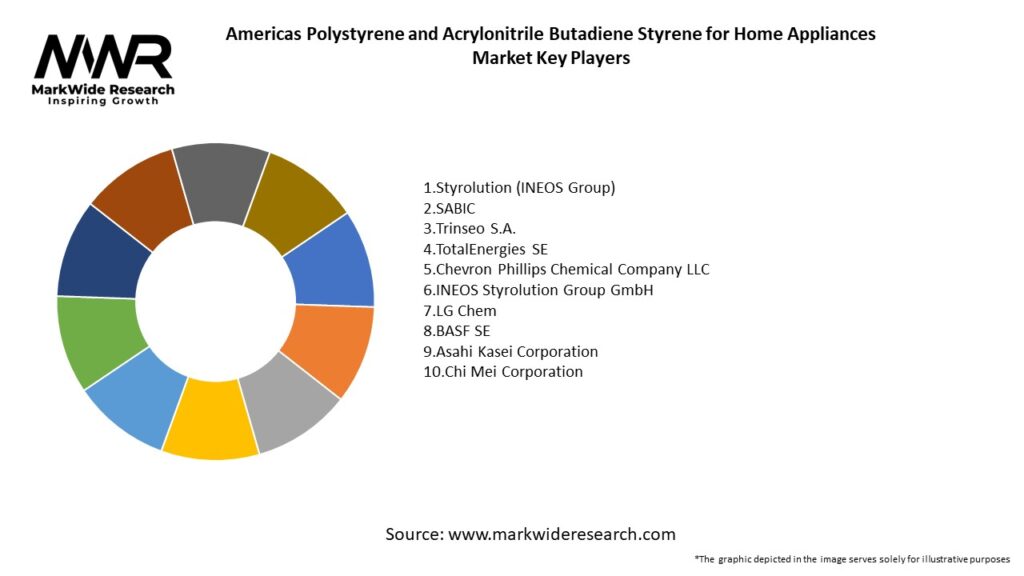

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights:

Market Drivers:

Market Restraints:

Market Opportunities:

Market Dynamics:

The Americas Polystyrene and ABS for Home Appliances Market operate within a dynamic landscape influenced by consumer trends, technological advancements, regulatory changes, and environmental considerations. Understanding these dynamics is essential for stakeholders to navigate challenges and capitalize on opportunities.

Regional Analysis:

Regional variations in the market are influenced by factors such as manufacturing capabilities, consumer preferences, and regulatory frameworks.

Competitive Landscape:

Leading Companies in the Americas Polystyrene and ABS for Home Appliances Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation:

The market can be segmented based on various factors:

Segmentation allows stakeholders to tailor their strategies to specific types of home appliances, material preferences, and sustainability considerations.

Category-wise Insights:

Key Benefits for Industry Participants and Stakeholders:

SWOT Analysis:

Understanding these factors through a SWOT analysis enables stakeholders to formulate strategies that leverage strengths, address weaknesses, capitalize on opportunities, and mitigate threats.

Market Key Trends:

Covid-19 Impact:

Key Industry Developments:

Analyst Suggestions:

Future Outlook:

The Americas Polystyrene and ABS for Home Appliances Market are poised for growth in the coming years. While environmental considerations pose challenges, innovations in sustainable materials, design practices, and collaboration across the supply chain will shape the future of the market. The industry’s ability to adapt to changing consumer preferences and regulatory landscapes will be critical for sustained success.

Conclusion:

In conclusion, the Americas Polystyrene and ABS for Home Appliances Market play a vital role in enhancing the performance, aesthetics, and durability of home appliances. While facing challenges related to environmental concerns and evolving regulations, the market presents opportunities for innovation and sustainability. Stakeholders must prioritize investments in sustainable solutions, collaborate for industry-wide innovation, and adapt to digital trends to ensure continued growth and resilience in the dynamic home appliances sector.

What is Polystyrene and Acrylonitrile Butadiene Styrene?

Polystyrene and Acrylonitrile Butadiene Styrene are thermoplastic polymers widely used in various applications, including home appliances, due to their durability, impact resistance, and ease of processing.

Who are the key players in the Americas Polystyrene and Acrylonitrile Butadiene Styrene for Home Appliances Market?

Key players in the Americas Polystyrene and Acrylonitrile Butadiene Styrene for Home Appliances Market include BASF, INEOS Styrolution, and SABIC, among others.

What are the growth factors driving the Americas Polystyrene and Acrylonitrile Butadiene Styrene for Home Appliances Market?

The growth of the Americas Polystyrene and Acrylonitrile Butadiene Styrene for Home Appliances Market is driven by increasing demand for lightweight and energy-efficient appliances, as well as advancements in polymer technology.

What challenges does the Americas Polystyrene and Acrylonitrile Butadiene Styrene for Home Appliances Market face?

Challenges in the Americas Polystyrene and Acrylonitrile Butadiene Styrene for Home Appliances Market include fluctuating raw material prices and environmental concerns regarding plastic waste management.

What opportunities exist in the Americas Polystyrene and Acrylonitrile Butadiene Styrene for Home Appliances Market?

Opportunities in the Americas Polystyrene and Acrylonitrile Butadiene Styrene for Home Appliances Market include the development of sustainable materials and the growing trend of smart home appliances that require advanced materials.

What trends are shaping the Americas Polystyrene and Acrylonitrile Butadiene Styrene for Home Appliances Market?

Trends in the Americas Polystyrene and Acrylonitrile Butadiene Styrene for Home Appliances Market include the increasing use of recycled materials and innovations in polymer blends that enhance performance and reduce environmental impact.

Americas Polystyrene and Acrylonitrile Butadiene Styrene for Home Appliances Market

| Segmentation Details | Description |

|---|---|

| Product Type | Polystyrene, Acrylonitrile Butadiene Styrene, High Impact Polystyrene, Expanded Polystyrene |

| Application | Refrigerators, Air Conditioners, Washing Machines, Microwaves |

| End Use Industry | Consumer Electronics, Home Appliances, Packaging, Construction |

| Grade | General Purpose, High Impact, Flame Retardant, Food Grade |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at