444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

Market Overview

The United States Marine Composites Market refers to the industry segment within the United States that deals with the production, distribution, and utilization of composites materials in marine applications. Marine composites are advanced materials that offer superior strength, durability, and corrosion resistance compared to traditional materials such as steel and aluminum. These materials find extensive usage in the construction of boats, yachts, ships, and other marine structures.

Meaning

Marine composites are composite materials specifically designed and engineered for use in marine environments. They are made by combining two or more materials with significantly different physical or chemical properties to create a new material with enhanced characteristics. The combination of different materials allows for the optimization of properties such as strength, weight, and resistance to environmental factors like saltwater, UV radiation, and extreme temperatures. Marine composites provide an excellent alternative to traditional materials due to their ability to withstand the harsh conditions encountered in marine applications.

Executive Summary

The United States Marine Composites Market is experiencing significant growth due to the numerous advantages offered by composites materials over conventional materials. The market is being driven by factors such as increasing demand for lightweight and fuel-efficient marine vessels, growing preference for composites due to their superior corrosion resistance, and rising investments in marine infrastructure development. However, the market also faces challenges such as high material and production costs, regulatory constraints, and the need for skilled labor. Despite these challenges, the market presents several opportunities for growth, such as the development of sustainable composites and the adoption of advanced manufacturing technologies.

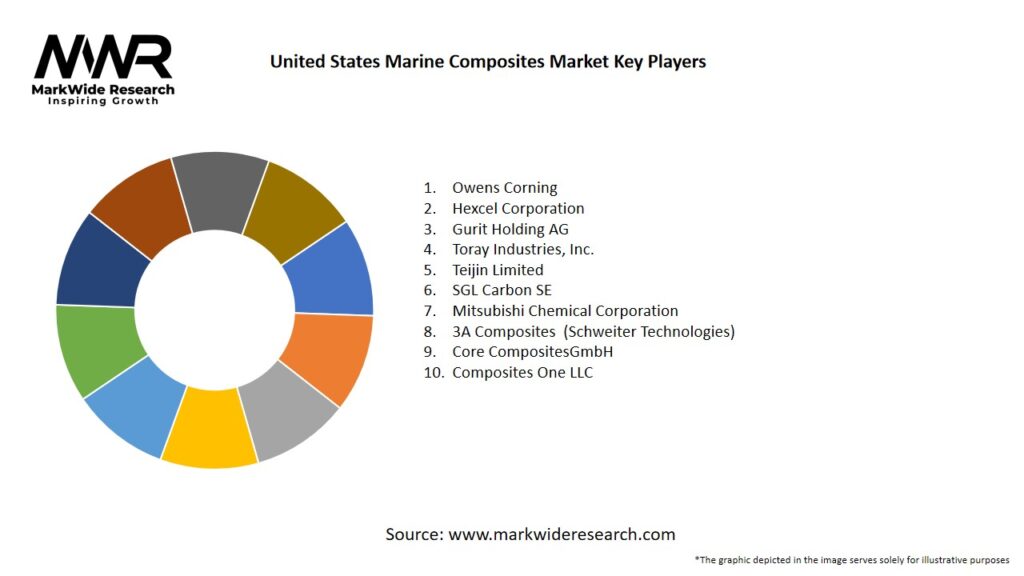

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The United States Marine Composites Market is influenced by various dynamic factors that shape its growth trajectory. These dynamics include market drivers, restraints, and opportunities. The demand for lightweight and fuel-efficient marine vessels, superior corrosion resistance, and growing investments in marine infrastructure are driving market growth. However, challenges such as high material and production costs, regulatory constraints, and the need for skilled labor can hinder market expansion. To capitalize on the market opportunities, manufacturers must focus on developing sustainable composites, adopting advanced manufacturing technologies, and exploring emerging applications.

The United States Marine Composites Market is influenced by several key factors:

Regional Analysis

The United States Marine Composites Market exhibits unique trends influenced by regional characteristics:

Competitive Landscape

Leading Companies in the United States Marine Composites Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

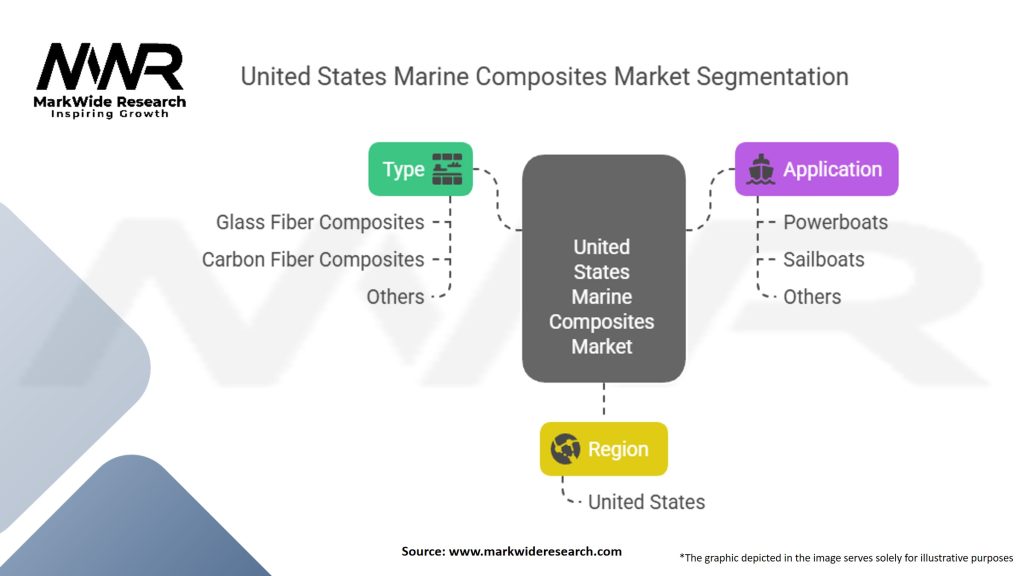

Segmentation

The United States Marine Composites Market can be segmented based on various criteria for deeper insights:

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

A SWOT analysis of the United States Marine Composites Market provides a comprehensive understanding of its strengths, weaknesses, opportunities, and threats.

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic had a significant impact on the United States Marine Composites Market. The restrictions imposed to control the spread of the virus disrupted supply chains, leading to raw material shortages and production delays. The temporary closure of shipyards, boatbuilding facilities, and other marine infrastructure projects further dampened market growth. However, the pandemic also highlighted the need for resilient and sustainable marine solutions, leading to increased interest in marine composites. As the industry recovers from the pandemic, there is an opportunity for market players to capitalize on the growing demand for lightweight, durable, and eco-friendly marine composites.

Key Industry Developments

Analyst Suggestions

Future Outlook

The United States Marine Composites Market is poised for significant growth in the coming years. The demand for lightweight and fuel-efficient marine vessels, coupled with the need for corrosion-resistant materials, will drive the adoption of marine composites. Advancements in manufacturing technologies and the development of sustainable composites will further propel market expansion. However, manufacturers must address challenges related to cost, regulation, and skilled labor to unlock the full potential of the market. By focusing on innovation, sustainability, and collaboration, industry participants can capitalize on the growing opportunities and shape the future of the marine composites market.

Conclusion

The United States Marine Composites Market offers immense opportunities for manufacturers, driven by the demand for lightweight, corrosion-resistant, and eco-friendly materials. Despite challenges related to cost and regulation, the market is expected to witness steady growth. The integration of advanced manufacturing technologies, the development of sustainable composites, and collaboration among industry stakeholders will be key to unlocking the market’s full potential. With strategic investments in research and development and a focus on meeting evolving market demands, industry participants can position themselves for success in the dynamic marine composites market.

What are marine composites in the context of the United States Marine Composites?

Marine composites refer to materials made from two or more constituent materials that are used in the construction of marine vessels and structures. These composites are designed to provide enhanced strength, durability, and resistance to corrosion, making them ideal for applications in the marine industry.

Who are the key players in the United States Marine Composites Market?

Key players in the United States Marine Composites Market include companies such as Hexcel Corporation, Gurit Holding AG, and Owens Corning, among others. These companies are involved in the production and supply of advanced composite materials for various marine applications.

What are the main drivers of growth in the United States Marine Composites Market?

The growth of the United States Marine Composites Market is driven by the increasing demand for lightweight and fuel-efficient vessels, advancements in composite manufacturing technologies, and the rising focus on sustainability in marine construction.

What challenges does the United States Marine Composites Market face?

The United States Marine Composites Market faces challenges such as high production costs associated with advanced composite materials and the need for specialized skills in manufacturing and repair. Additionally, regulatory compliance can pose hurdles for companies in this sector.

What opportunities exist in the United States Marine Composites Market?

Opportunities in the United States Marine Composites Market include the growing trend towards electric and hybrid marine vessels, which require innovative composite solutions, and the expansion of recreational boating, which increases demand for lightweight and durable materials.

What trends are shaping the United States Marine Composites Market?

Trends in the United States Marine Composites Market include the increasing use of bio-based composites, advancements in nanotechnology for enhanced material properties, and a shift towards modular construction techniques in shipbuilding.

United States Marine Composites Market:

| Segmentation | Details |

|---|---|

| Type | Glass Fiber Composites, Carbon Fiber Composites, Others |

| Application | Powerboats, Sailboats, Others |

| Region | United States |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the United States Marine Composites Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at