444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The 3D printed implants market refers to the market for medical implants that are manufactured using 3D printing technology. 3D printing, also known as additive manufacturing, is a revolutionary technology that allows the creation of complex three-dimensional structures using layer-by-layer printing of materials. In the field of healthcare, 3D printed implants offer numerous advantages such as customization, enhanced implant design, improved patient outcomes, and reduced surgical complications. This market overview provides a comprehensive analysis of the 3D printed implants market, including its meaning, executive summary, key market insights, drivers, restraints, opportunities, market dynamics, regional analysis, competitive landscape, segmentation, category-wise insights, key benefits for industry participants and stakeholders, SWOT analysis, market key trends, the impact of Covid-19, key industry developments, analyst suggestions, future outlook, and a concluding summary.

Meaning

3D printed implants are medical implants that are produced using additive manufacturing techniques. In this process, a three-dimensional object is created by adding successive layers of material, usually a biocompatible material, based on a digital model. 3D printing technology allows for the creation of highly customized implants that precisely fit the patient’s anatomy. The implants can be made from various materials, including metals, polymers, and ceramics, depending on the specific requirements of the implant and the patient.

Executive Summary

The 3D printed implants market has witnessed significant growth in recent years, driven by factors such as the increasing adoption of additive manufacturing in healthcare, advancements in 3D printing technology, and the growing demand for customized medical implants. The executive summary provides a concise overview of the market, highlighting key market insights, trends, drivers, restraints, and opportunities. It also presents a summary of the impact of Covid-19 on the market and outlines the future outlook for the 3D printed implants industry.

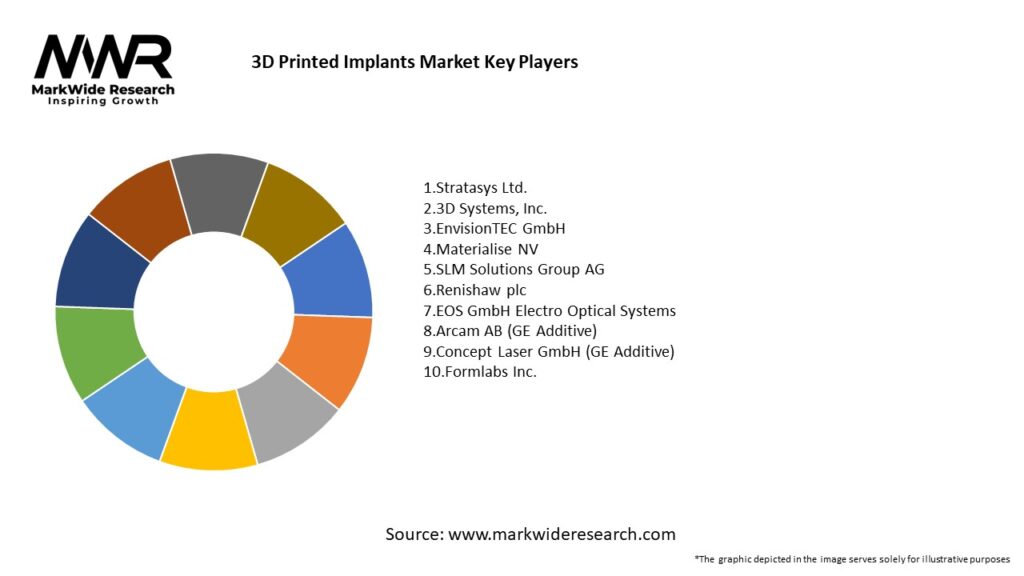

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The 3D printed implants market is dynamic, driven by the increasing demand for customized implants, advancements in 3D printing technology, the prevalence of orthopedic and dental disorders, cost and time efficiency, and regulatory approvals. However, limitations in material options, high initial investment, regulatory challenges, limited awareness and adoption, and ethical and legal considerations pose restraints to market growth. Opportunities lie in expanding into new medical specialties, developing novel materials, collaboration with healthcare institutions, patient-specific implants, and personalized medicine. A comprehensive understanding of the market dynamics is crucial for stakeholders to navigate the evolving landscape and capitalize on growth opportunities.

Regional Analysis

The 3D printed implants market varies across different regions due to variations in healthcare infrastructure, regulatory frameworks, technological advancements, and patient awareness. North America and Europe dominate the market, driven by well-established healthcare systems, high adoption of innovative technologies, and strong research and development activities. Asia-Pacific and Latin America show significant potential for market growth due to expanding healthcare infrastructure, increasing disposable incomes, and a growing focus on advanced healthcare solutions. Africa, although facing challenges related to limited resources and infrastructure, presents opportunities for the adoption of 3D printed implants through strategic collaborations and awareness initiatives.

Competitive Landscape

Leading companies in the 3D Printed Implants Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

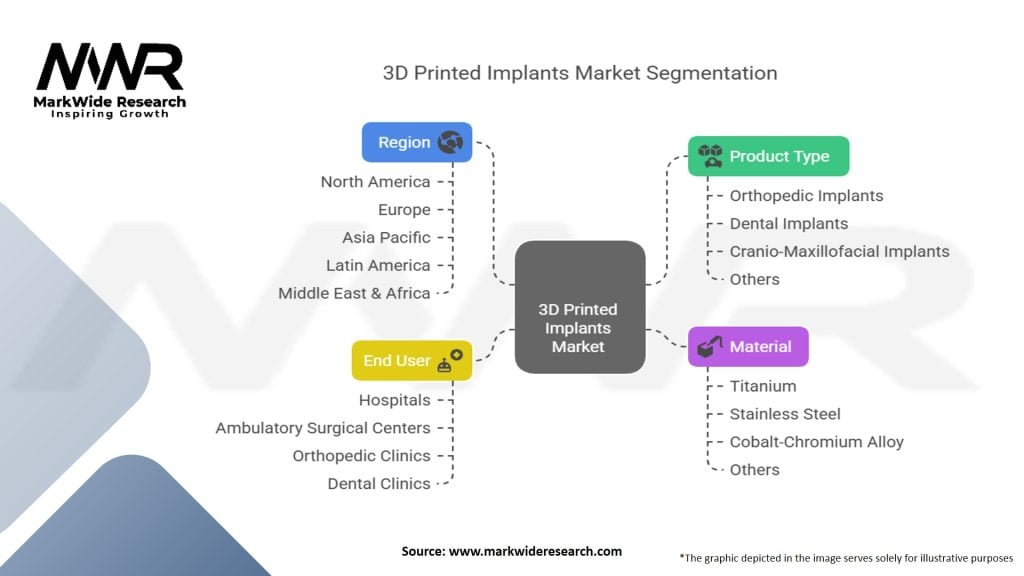

Segmentation

The 3D printed implants market can be segmented based on the type of implant, material used, medical specialty, and geography. Different types of implants include orthopedic implants, dental implants, craniofacial implants, and others. Materials used for 3D printing implants include metals, polymers, ceramics, and biocompatible composites. Medical specialties for 3D printed implants include orthopedics, dentistry, craniofacial surgery, cardiovascular, and others. Geographically, the market can be divided into North America, Europe, Asia-Pacific, Latin America, and Africa.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic has had both positive and negative impacts on the 3D printed implants market. On one hand, the pandemic has highlighted the importance of 3D printing technology in rapidly manufacturing essential medical supplies, including personal protective equipment (PPE) and medical device components. On the other hand, disruptions in the global supply chain and economic uncertainties have posed challenges to the market. However, the pandemic has also emphasized the need for resilient and localized manufacturing capabilities, which align with the strengths of 3D printing technology.

Key Industry Developments

Analyst Suggestions

Future Outlook

The future outlook for the 3D printed implants market is optimistic. Advancements in 3D printing technology, expanding material options, increased adoption by healthcare institutions, and growing patient demand for customized solutions are expected to drive market growth. The market is likely to witness further collaborations, research and development efforts, and regulatory advancements. As 3D printing continues to revolutionize the healthcare industry, the potential for personalized medicine and improved patient outcomes through 3D printed implants is significant.

Conclusion

The 3D printed implants market holds great potential in revolutionizing the field of medical implants. The market overview provides a comprehensive understanding of the meaning, executive summary, key market insights, drivers, restraints, opportunities, market dynamics, regional analysis, competitive landscape, segmentation, category-wise insights, key benefits for industry participants and stakeholders, SWOT analysis, market key trends, the impact of Covid-19, key industry developments, analyst suggestions, future outlook, and a concluding summary. The market’s growth is driven by factors such as customization, technological advancements, expanding applications, and cost efficiency. While challenges related to material options, regulatory considerations, limited awareness, and ethical concerns exist, opportunities lie in new medical specialties, novel materials, collaboration, and personalized medicine. The future of the 3D printed implants market looks promising, with continued research and development, regulatory advancements, and increased adoption by healthcare institutions paving the way for improved patient outcomes and personalized healthcare solutions.

What are 3D printed implants?

3D printed implants are medical devices created using additive manufacturing techniques, allowing for customized shapes and sizes tailored to individual patient needs. These implants are commonly used in orthopedics, dental applications, and reconstructive surgery.

Who are the key players in the 3D printed implants market?

Key players in the 3D printed implants market include companies like Stratasys, Materialise, and Stryker, which are known for their innovative approaches to additive manufacturing in the medical field, among others.

What are the main drivers of growth in the 3D printed implants market?

The growth of the 3D printed implants market is driven by the increasing demand for personalized medical solutions, advancements in 3D printing technology, and the rising prevalence of chronic diseases requiring surgical interventions.

What challenges does the 3D printed implants market face?

Challenges in the 3D printed implants market include regulatory hurdles, the need for extensive testing and validation, and concerns regarding the long-term biocompatibility of materials used in implants.

What future opportunities exist in the 3D printed implants market?

Future opportunities in the 3D printed implants market include the development of new biomaterials, expansion into emerging markets, and the integration of artificial intelligence to enhance design and manufacturing processes.

What trends are shaping the 3D printed implants market?

Trends in the 3D printed implants market include the increasing use of patient-specific designs, the rise of bio-printing technologies, and collaborations between medical professionals and manufacturers to improve implant functionality.

3D Printed Implants Market

| Segmentation Details | Description |

|---|---|

| Product Type | Orthopedic Implants, Dental Implants, Cranio-Maxillofacial Implants, Others |

| Material | Titanium, Stainless Steel, Cobalt-Chromium Alloy, Others |

| End User | Hospitals, Ambulatory Surgical Centers, Orthopedic Clinics, Dental Clinics |

| Region | North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the 3D Printed Implants Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at