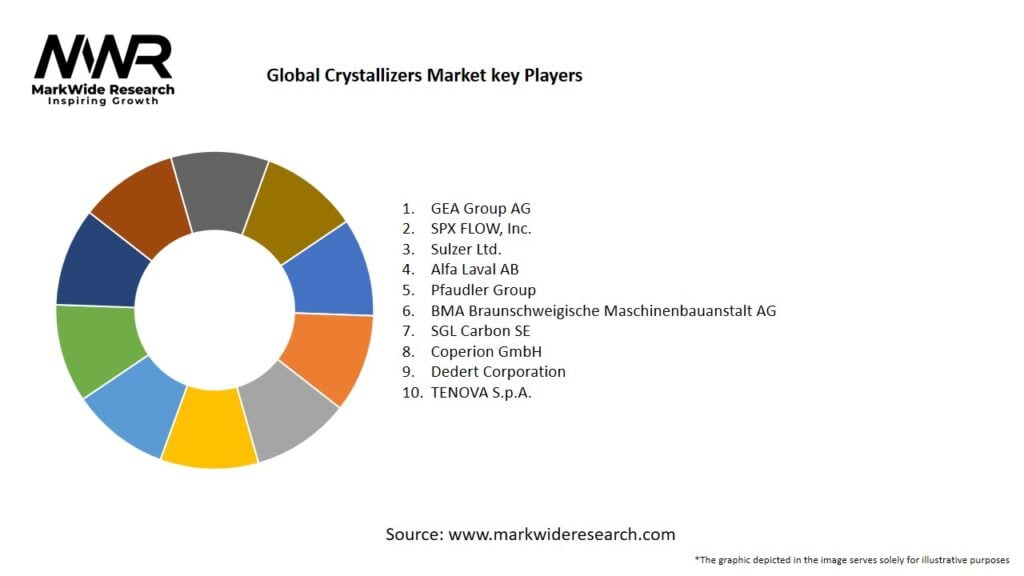

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

-

Pharma & Biotech Growth: Increased production of active pharmaceutical ingredients (APIs) with strict purity requirements drives adoption of advanced crystallizers.

-

Energy Efficiency Focus: Manufacturers are seeking crystallizers with lower thermal footprints and optimized heat recovery to reduce operational expenses.

-

Process Intensification: Continuous crystallization and modular skid‑mounted systems are gaining traction for seamless integration into continuous manufacturing lines.

-

Sustainability Compliance: Strict wastewater discharge norms boost demand for crystallizers in recovery of salts and removal of harmful byproducts.

-

Digitalization & Automation: Incorporation of process analytical technology (PAT) and real‑time monitoring enhances control over crystal attributes and reduces batch variability.

Market Drivers

-

Stringent Quality Standards: Regulatory bodies like FDA and EMA mandate tight control over crystal size, purity, and polymorphism in pharmaceutical products.

-

Environmental Regulations: Limits on effluent discharge encourage recovery of valuable salts and solids from industrial wastewater via crystallization.

-

Rising Specialty Chemicals Production: Growth in compounds such as citric acid, MSG, and fine chemicals fuels crystallizer demand in food & chemical sectors.

-

Process Intensification Trends: The shift from batch to continuous processes in chemical and pharma manufacturing drives demand for continuous crystallizers.

-

Energy Cost Pressures: High energy prices push manufacturers to adopt evaporative and cooling crystallizers with heat integration and optimized vapor recompression.

Market Restraints

-

High CapEx: Advanced crystallizer systems and associated utilities (chillers, vacuum units) require significant initial investment.

-

Complex Scale‑up: Translating lab‑scale crystallization to industrial scale with consistent product quality poses technical challenges.

-

Operational Expertise: Effective crystallization demands specialized know‑how in solubility, nucleation, and crystal growth kinetics.

-

Maintenance Requirements: Fouling and mechanical wear in evaporative and forced‑circulation units increase downtime and lifecycle costs.

-

Limited Awareness in SMEs: Smaller manufacturers may lack awareness or resources to invest in optimized crystallization solutions.

Market Opportunities

-

Modular & Skid Solutions: Prefabricated, plug‑and‑play crystallizer packages facilitate rapid deployment in existing production lines.

-

Continuous Crystallization Platforms: PAT‑enabled continuous crystallizers allow tighter control, reduced footprint, and higher throughput.

-

Hybrid Technologies: Combining cooling with anti‑solvent or pH‑shift crystallization opens new avenues for difficult-to-crystallize materials.

-

Digital Twins & AI: Using digital twins for process simulation and AI algorithms for predictive control can optimize yield and crystal quality.

-

Emerging Market Expansion: Rapid industrial growth in Southeast Asia, Latin America, and Middle East presents new sales channels for crystallizer OEMs.

Market Dynamics

-

Supply Side: Leading equipment manufacturers invest in R&D for robust materials (e.g., corrosion‑resistant alloys), scalable designs, and integrated control systems.

-

Demand Side: End‑users prioritize total cost of ownership (TCO), lifecycle service agreements, and vendor reliability when specifying crystallization equipment.

-

Economic Factors: Fluctuations in energy costs and raw material prices influence the selection of evaporative vs. cooling crystallizer technologies.

-

Technological Trends: Advances in heat pump integration for vacuum crystallizers and the use of smart sensors for on‑line particle measurement drive industry innovation.

Regional Analysis

-

Asia‑Pacific: Largest volume market due to booming chemical, pharmaceutical, and food processing sectors in China, India, and Southeast Asia.

-

North America: Strong demand for high‑end, continuous, and PAT‑enabled crystallizers driven by pharma innovation hubs in the U.S. and Canada.

-

Europe: Stringent environmental and quality regulations spur adoption of advanced wastewater recovery and high‑purity crystallization systems.

-

Latin America: Emerging investments in chemical and food industries in Brazil and Mexico create opportunities for midsized crystallizer installations.

-

Middle East & Africa: Growth in petrochemicals and desalination byproducts management drives demand for large-scale evaporative and vacuum crystallizers.

Competitive Landscape

Leading Companies in the Global Crystallizers Market:

- GEA Group AG

- SPX FLOW, Inc.

- Sulzer Ltd.

- Alfa Laval AB

- Pfaudler Group

- BMA Braunschweigische Maschinenbauanstalt AG

- SGL Carbon SE

- Coperion GmbH

- Dedert Corporation

- TENOVA S.p.A.

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

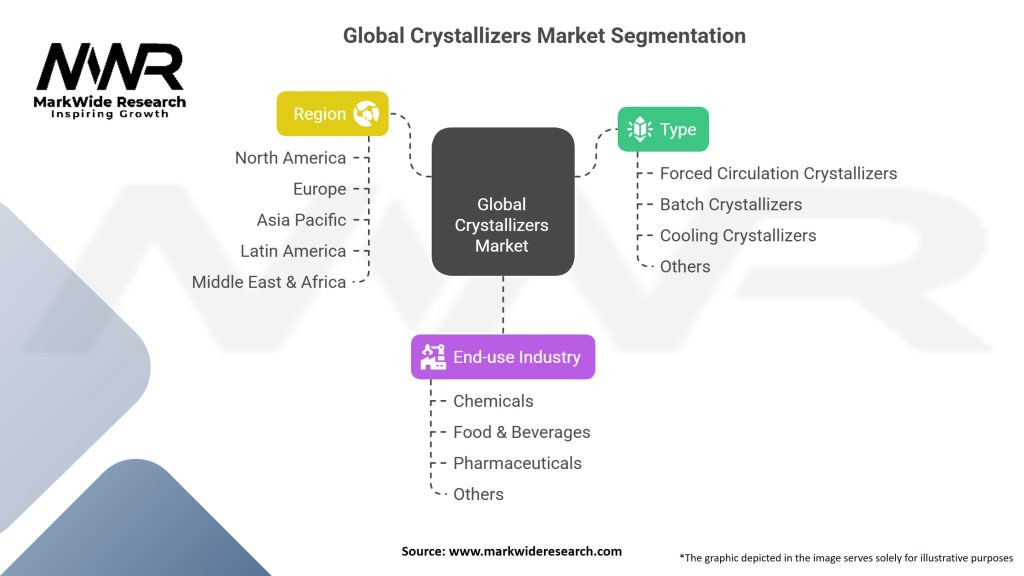

Segmentation

-

By Crystallizer Type:

-

Cooling Crystallizers

-

Evaporative Crystallizers

-

Forced Circulation Crystallizers

-

Vacuum Crystallizers

-

Draft Tube Baffle (DTB) Crystallizers

-

-

By End‑Use Industry:

-

Pharmaceuticals & Fine Chemicals

-

Food & Beverage

-

Wastewater Treatment

-

Inorganic Chemicals (e.g., salts)

-

Petrochemicals & Chemicals

-

-

By Deployment Mode:

-

Batch Crystallization

-

Continuous Crystallization

-

-

By Region:

-

North America

-

Europe

-

Asia‑Pacific

-

Latin America

-

Middle East & Africa

-

Category-wise Insights

-

Pharmaceutical & Fine Chemicals: Demand for narrow particle size distribution and polymorph control drives continuous and PAT‑enabled crystallizers.

-

Food & Beverage: Applications such as sugar recovery and salt crystallization rely on large evaporative and cooling crystallizers.

-

Wastewater Treatment: Recovery of salts, gypsum, and alum sludge uses vacuum and forced circulation crystallizers for volume reduction.

-

Inorganic Chemicals: High‑purity inorganic salt production (e.g., sodium sulfate) benefits from energy‑efficient evaporative crystallizers.

Key Benefits for Industry Participants and Stakeholders

-

High Purity & Yield: Consistent crystal quality reduces downstream purification costs.

-

Energy & Cost Savings: Integrated heat recovery and optimized residence times lower operating expenses.

-

Improved Throughput: Continuous crystallization maximizes production capacity.

-

Regulatory Compliance: Reliable removal of impurities and byproducts ensures environmental and product‑quality adherence.

-

Data-Driven Control: PAT and real‑time analytics prevent batch failures and facilitate rapid troubleshooting.

SWOT Analysis

Strengths:

-

Technological Maturity: Decades of innovation across industries ensure robust, reliable solutions.

-

Diverse Applications: Wide applicability from pharma to wastewater treatment broadens market potential.

-

High ROI: Improved purity and yield justify capital investment.

Weaknesses:

-

High Capital Expenditure: Significant upfront investment in sophisticated crystallization systems.

-

Complex Operation: Requires skilled operators and advanced process modeling for scale‑up.

-

Maintenance Intensity: Mechanical and thermal components demand regular upkeep.

Opportunities:

-

Continuous Manufacturing: Pharma’s shift to continuous processes opens new markets.

-

Digital Integration: AI and digital twins for predictive control can unlock efficiency gains.

-

Emerging Economies: Industrial growth in Asia, Latin America, and Africa offers expansion avenues.

Threats:

-

Energy Price Volatility: Fluctuating utility costs can impact operating economics.

-

Regulatory Changes: New environmental or safety regulations may require costly retrofits.

-

Competitive Alternatives: Emerging separation technologies (e.g., membrane crystallization) could erode market share.

Market Key Trends

-

Shift to Continuous Crystallization: Enhanced control and productivity for API and specialty chemical production.

-

Process Analytical Technology (PAT): Real‑time monitoring of crystal attributes enables proactive control.

-

Hybrid Crystallization Methods: Combining cooling, anti‑solvent, and evaporative techniques for challenging separations.

-

Energy Integration: Adoption of mechanical vapor recompression and heat pumps to minimize thermal energy consumption.

-

Modular Skid Systems: Prefabricated crystallizer units reduce installation time and onsite risks.

Covid-19 Impact

-

Supply Chain Disruptions: Initial delays in specialized equipment deliveries highlighted the need for localized manufacturing.

-

Pharma Demand Surge: Vaccines and therapeutics manufacturing accelerated investment in high‑purity crystallization systems.

-

Remote Monitoring Adoption: Travel restrictions spurred deployment of digital monitoring and remote service capabilities.

-

Operational Resilience: Producers prioritized robust, automated crystallization to minimize on‑site staffing and ensure continuity.

Key Industry Developments

-

Digital Twin Implementations: Major OEMs launched digital twin platforms for crystallizer performance simulation and optimization.

-

AI‑Driven PAT Solutions: Integration of machine learning models for predictive nucleation control and crystal size distribution management.

-

Strategic Acquisitions: Leading players acquired specialty PAT and control system firms to augment crystallization portfolios.

-

Collaborative Research: Industry consortia working on standardized continuous crystallization protocols for pharma applications.

-

Circular Economy Initiatives: Wastewater treatment crystallizers deployed for zero‑liquid discharge (ZLD) projects, recovering valuable salts.

Analyst Suggestions

-

Invest in Continuous Technologies: Capitalize on the pharma continuous manufacturing trend by offering integrated continuous crystallizer solutions.

-

Enhance Digital Offerings: Develop comprehensive PAT and digital twin services to provide end‑to‑end process control.

-

Expand After‑Sales Services: Offer remote monitoring, predictive maintenance, and operator training packages to drive recurring revenue.

-

Focus on Sustainability: Promote energy‑efficient designs and materials recovery capabilities to meet customer ESG goals.

-

Target Emerging Regions: Strengthen local partnerships and modular skids to address rapid industrialization in Asia‑Pacific and Latin America.

Future Outlook

The Global Crystallizers Market is poised for sustained growth as industries prioritize product quality, process efficiency, and environmental compliance. Key factors shaping the future include:

-

Broader Adoption of PAT‑Enabled Systems: Widespread use of real‑time analytics will minimize batch variability and accelerate regulatory approvals.

-

Modular & Skid‑Mounted Solutions Surge: Prefabrication will reduce lead times and onsite engineering costs.

-

Integration with Industry 4.0: AI, IoT, and cloud connectivity will become standard, enabling smart, self‑optimizing crystallization processes.

-

Energy Transition Impacts: Rising energy costs will drive adoption of mechanical vapor recompression and heat pump technologies in evaporative crystallizers.

-

Regulatory Harmonization: Standardized guidelines for continuous crystallization in pharma will unlock large new markets.

Conclusion

The Global Crystallizers Market stands at the intersection of advanced process technology, digital transformation, and sustainability imperatives. As pharmaceutical, chemical, food, and environmental sectors demand ever‑higher purity, efficiency, and resource recovery, crystallization equipment will continue to evolve. Stakeholders who invest in continuous, digital‑ready, and energy‑efficient crystallizer solutions—while fostering strong service and regional partnerships—will lead this dynamic market into its next growth phase.