444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

The global dodecanedioic acid market is experiencing significant growth and is projected to expand at a substantial rate in the coming years. Dodecanedioic acid, also known as DDDA, is a dicarboxylic acid with a chemical formula of C12H22O4. It is primarily used in the production of nylon 6,12, coatings, adhesives, and various other applications. DDDA is gaining prominence in several industries due to its unique properties and versatile applications.

Dodecanedioic acid is an organic compound that belongs to the family of dicarboxylic acids. It is a white crystalline solid with a slight odor. DDDA is produced through the oxidation of long-chain alkanes or by the fermentation of long-chain fatty acids. It possesses excellent thermal stability, high melting point, and good solubility in organic solvents. These properties make it suitable for various end-use applications.

Executive Summary

The global dodecanedioic acid market is witnessing significant growth, driven by the rising demand for nylon 6,12 in the automotive, textile, and electrical industries. The increasing use of DDDA in coatings, adhesives, and corrosion inhibitors is further propelling market growth. Additionally, the growing awareness about sustainable products and the shift towards bio-based chemicals are creating new opportunities in the market.

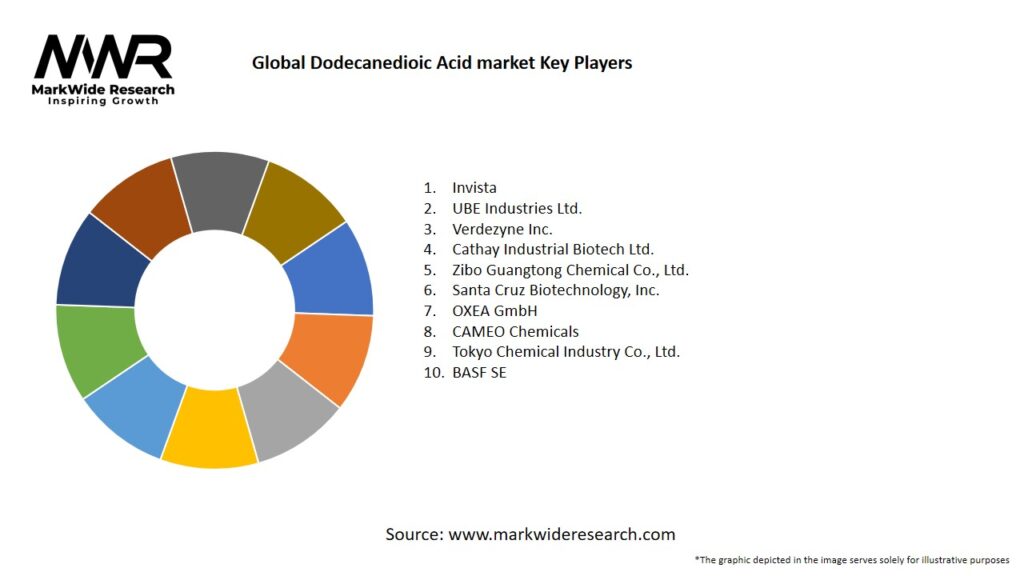

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Bio‑based Production Gains Share: Microbial routes now account for >20 % of global DDDA output, with capacity expansions in North America and Europe.

Nylon 6,12 Replaces Traditional Polyamides: Growth in automotive fuel lines and electrical cables uses nylon 6,12 for its lower water absorption and high dimensional stability.

High‑performance Lubricants & Plasticizers: DDDA derivatives are increasingly used in biodegradable hydraulic fluids and low‑volatility plasticizers.

Asia‑Pacific Leads Consumption: Rapid industrialization in China and India drives demand for engineering plastics and specialty chemicals.

M&A and JV Activity: Consolidation among chemical majors and biotech firms accelerates technology transfer and market penetration.

Market Drivers

Sustainability Trends: Corporate commitments to reduce carbon footprint boost bio‑DDDA adoption.

Automotive Lightweighting: DDDA‑based nylon 6,12 enables lighter, fuel‑efficient vehicles.

Performance Polymer Demand: Electronics and high‑performance fibers rely on DDDA’s thermal properties.

Regulatory Incentives: Subsidies and tax credits for renewable chemical production improve project economics.

Feedstock Diversity: Availability of waste vegetable oils and tall oil fatty acids offers secure, low‑cost inputs.

Market Restraints

High Production Cost: Bio‑DDDA costs remain 20‑30 % above petrochemical equivalents.

Feedstock Price Volatility: Fluctuating prices for oleic and ricinoleic acids impact margins.

Scale‑up Challenges: Commercializing fermentation at large scale requires significant capital and technical expertise.

Competition from Alternative Diacids: Adipic and sebacic acids maintain large, established supply chains.

Regulatory Uncertainty: Shifting environmental policies and trade tariffs can disrupt supply chains.

Market Opportunities

Integrated Biorefineries: Co‑locating DDDA production with biofuel plants to utilize glycerol and fatty acid streams.

High‑value Specialty Applications: Medical polymer excipients and biodegradable coatings offer premium margins.

Emerging Markets Penetration: Expanding capacities in Southeast Asia and Latin America to meet local demand.

Technological Licensing: Licensing fermentation and continuous oxidation technologies to regional producers.

Circular Economy Synergies: Converting plastic waste pyrolysis oils into DDDA via catalytic processes.

Market Dynamics

The global dodecanedioic acid market is driven by several factors. The increasing demand for nylon 6,12, particularly in the automotive and textile sectors, is one of the primary drivers. Nylon 6,12 is known for its excellent mechanical properties, chemical resistance, and low moisture absorption, making it suitable for various applications. Additionally, the use of dodecanedioic acid in coatings, adhesives, and corrosion inhibitors is boosting market growth.

However, the market faces some challenges. Fluctuating prices of raw materials, such as butadiene and adipic acid, impact the overall cost of production. Moreover, stringent environmental regulations regarding the use of certain chemicals in the production process pose a challenge for market players. Furthermore, the market faces intense competition from alternative products, such as nylon 6,6 and other bio-based chemicals.

Despite these challenges, the market presents several opportunities. The expansion of application areas, such as personal care products and pharmaceuticals, opens up new growth prospects. Moreover, emerging economies with growing industrial sectors offer untapped opportunities for market players. The shift towards bio-based chemicals and the increasing demand for sustainable products also create favorable conditions for market growth.

Regional Analysis

The global dodecanedioic acid market is geographically segmented into North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa.

Competitive Landscape

Leading Companies in the Global Dodecanedioic Acid Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

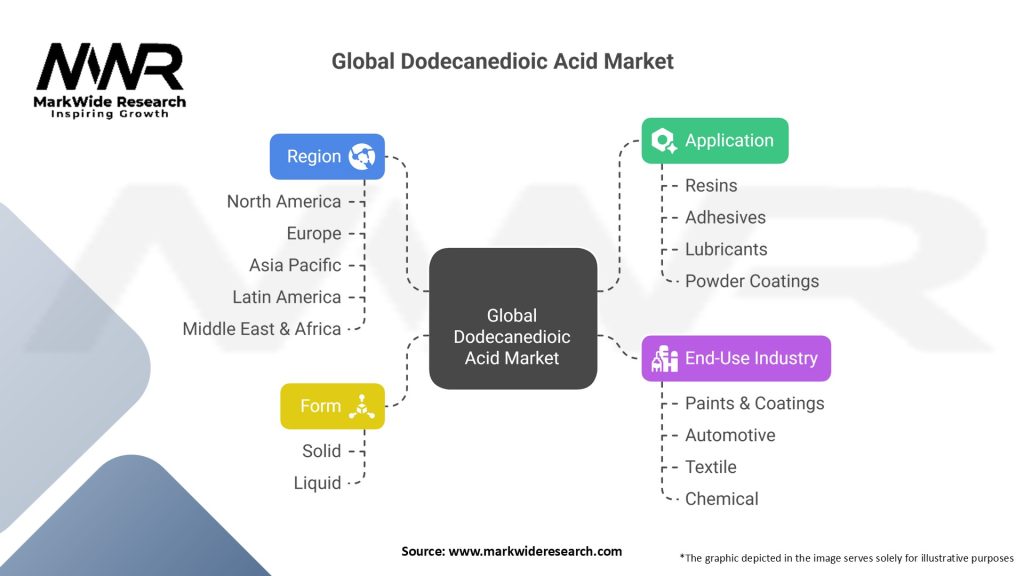

Segmentation

The global dodecanedioic acid market can be segmented based on application and end-use industry.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The global dodecanedioic acid market was affected by the COVID-19 pandemic. The lockdowns and restrictions imposed by governments disrupted supply chains and hampered industrial activities. The automotive and textile sectors, major consumers of nylon 6,12, experienced a decline in demand during the pandemic. However, as economies recover and industries resume operations, the market is expected to rebound.

Key Industry Developments

Analyst Suggestions

Future Outlook

The global dodecanedioic acid market is expected to witness steady growth in the coming years. The increasing demand for nylon 6,12, coatings, adhesives, and corrosion inhibitors will be the primary growth drivers. The market will also benefit from the expanding application areas and the shift towards bio-based chemicals. However, challenges such as fluctuating raw material prices and stringent environmental regulations will need to be addressed.

Conclusion

The global dodecanedioic acid market is poised for significant growth, driven by the rising demand for nylon 6,12 and its various applications. Dodecanedioic acid offers unique properties and finds extensive use in coatings, adhesives, and corrosion inhibitors. The market is highly competitive, with key players focusing on innovation and strategic collaborations. Despite challenges, such as price fluctuations and environmental regulations, the market presents ample opportunities for industry participants. The future outlook remains positive, with sustained growth expected in the coming years.

What is dodecanedioic acid?

Dodecanedioic acid is a linear dicarboxylic acid with twelve carbon atoms, commonly used in the production of polyamides, coatings, and plasticizers. It plays a significant role in various industrial applications due to its unique chemical properties.

Who are the key players in the Global Dodecanedioic Acid market?

Key players in the Global Dodecanedioic Acid market include companies like Evonik Industries, BASF, and DuPont, which are known for their contributions to chemical manufacturing and innovation in dodecanedioic acid applications, among others.

What are the drivers of growth in the Global Dodecanedioic Acid market?

The growth of the Global Dodecanedioic Acid market is driven by increasing demand for high-performance polymers, rising applications in the automotive and electronics industries, and the growing trend towards sustainable materials.

What challenges does the Global Dodecanedioic Acid market face?

The Global Dodecanedioic Acid market faces challenges such as fluctuating raw material prices, environmental regulations impacting production processes, and competition from alternative materials that may limit market growth.

What opportunities exist in the Global Dodecanedioic Acid market?

Opportunities in the Global Dodecanedioic Acid market include the development of bio-based dodecanedioic acid, expanding applications in the textile and automotive sectors, and increasing investments in research and development for innovative uses.

What trends are shaping the Global Dodecanedioic Acid market?

Trends shaping the Global Dodecanedioic Acid market include a shift towards eco-friendly production methods, advancements in polymer technology, and a growing focus on circular economy practices within the chemical industry.

Global Dodecanedioic Acid Market:

| Segmentation | Details |

|---|---|

| Application | Resins, Adhesives, Lubricants, Powder Coatings, Others |

| End-Use Industry | Paints & Coatings, Automotive, Textile, Chemical, Others |

| Form | Solid, Liquid |

| Region | North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Global Dodecanedioic Acid Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at