444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

The global rotary cutters market has been experiencing significant growth in recent years. Rotary cutters, also known as rotary mowers or brush cutters, are versatile machines widely used in agriculture, forestry, landscaping, and industrial applications. They are designed to efficiently cut through dense vegetation, grass, and other tough materials. This market analysis aims to provide valuable insights into the current state of the global rotary cutters market, including key trends, market dynamics, regional analysis, competitive landscape, and future outlook.

Rotary cutters refer to mechanized cutting equipment equipped with rotating blades, usually powered by engines or power take-off (PTO) systems. These machines are designed to operate in various environments and terrains, making them ideal for applications such as land clearing, maintaining roadways, pasture management, and maintaining parks and recreational areas.

Executive Summary:

The global rotary cutters market has witnessed substantial growth due to increasing demand for efficient vegetation management equipment across diverse industries. The market is driven by factors such as the expanding agricultural sector, the need for land clearing and maintenance, and advancements in technology that enhance the performance and efficiency of rotary cutters. However, challenges such as high initial investment costs and limited awareness in certain regions can impede market growth. Despite these restraints, numerous opportunities exist in emerging economies and the adoption of eco-friendly and precision farming practices.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Packaging Sector Dominance: The flexible packaging industry accounts for over 40% of rotary cutter consumption, owing to high-volume film and laminate slitting requirements.

Blade Material Innovation: Tungsten-carbide-tipped and diamond-coated blades are gaining prominence for their superior wear resistance and prolonged life, especially in abrasive substrates.

Automation Integration: Approximately 30% of new slitter installations in 2024 featured automated cutter change and in-line blade-life monitoring systems to minimize manual labor and enhance safety.

Regional Production Shifts: Asia Pacific’s share of rotary cutter revenues grew from 28% in 2018 to 35% in 2024, reflecting rising manufacturing activity in China, India, and Southeast Asia.

SME Adoption: Small and medium-size converters are investing in modular rotary cutter packages to upgrade existing lines without full machine replacement, driving aftermarket blade sales.

Market Drivers

Flexible Packaging Growth: Expanding use of plastic films, laminates, and pouches in food and pharmaceuticals necessitates high-precision slitting with quality rotary cutters.

Automotive Lightweighting: Greater production of interior trim foams, textiles, and adhesives requires rotary cutters capable of processing composite materials with consistent accuracy.

Nonwoven Fabric Demand: Hygiene products, medical disposables, and filtration media rely on rotary cutters for fabric slitting and edge finishing in high-volume lines.

Waste Reduction Mandates: Regulatory pressure to minimize material waste is driving investments in precision slitting technologies that depend on sharp, well-balanced rotary cutters.

Labor Cost Optimization: Automated cutter change systems reduce manual blade replacement, offering labor savings and increased line uptime.

Market Restraints

High Initial Investment: Advanced cutter systems with automation and monitoring add substantial upfront cost, limiting adoption among cost-sensitive converters.

Blade Wear in Abrasive Materials: Continuous cutting of abrasive substrates (e.g., glass-fiber composites) accelerates blade wear, increasing maintenance frequency and operational expense.

Skilled Technician Shortage: Proper installation, alignment, and maintenance of rotary cutters require specialized training, posing challenges in regions with limited technical expertise.

Complex Changeover Procedures: Without quick-change systems, blade replacement and rebalance can be time-consuming, reducing the appeal of rotary cutters for multi-job converters.

Supply Chain Disruptions: Dependence on imported high-performance blade materials can lead to supply bottlenecks and long lead times.

Market Opportunities

Smart Cutter Systems: Embedding sensors for vibration analysis and blade life prediction enables condition-based maintenance, preventing unexpected failures.

Additive Manufacturing: 3D-printed cutter holders and adaptive mounting prototypes allow rapid customization for specialized slitting applications.

Long-Life Coatings: Development of ultra-hard diamond-like carbon (DLC) and ceramic coatings promises extended blade durability in demanding environments.

Local Manufacturing Partnerships: Establishing regional blade production and sharpening services in emerging markets reduces lead times and supports local converter needs.

Retrofit Solutions: Tailored rotary cutter retrofit kits for legacy slitting machines open aftermarket revenue streams for OEMs and distributors.

Market Dynamics

OEM vs. Aftermarket Sales: While OEMs supply complete cutter assemblies, independent blade-sharpening firms capture significant aftermarket business by offering faster turnarounds and lower costs.

Consolidation Trends: Mergers among industrial blade manufacturers are creating vertically integrated firms capable of supplying both blades and automated change systems.

Digital Transformation: Integration of IoT platforms for remote monitoring of cutter performance is emerging, enabling centralized analytics across multiple slitter lines.

Customization Demand: Converters require cutter solutions tailored to unique material blends and thicknesses, prompting OEMs to offer configurable cutter shafts and blade geometries.

Sustainability Focus: Recycling of worn blades and use of eco-friendly blade-sharpening fluids are gaining traction to reduce environmental impact.

Regional Analysis

North America: Mature market with high adoption of automated cutter systems in packaging and nonwovens; strong aftermarket services.

Europe: Focus on high-precision blades and advanced coatings driven by automotive and aerospace sectors; stringent quality standards.

Asia Pacific: Fastest-growing region, led by packaging expansion in China and India; emergence of local blade producers supporting cost-effective supply.

Latin America: Moderate growth tied to food-packaging investments and conversion of sugarcane bagasse into fiberboard, requiring rotary slitting.

Middle East & Africa: Nascent market; growth linked to regional petrochemical and composite-material manufacturing hubs.

Competitive Landscape:

Leading Companies in the Global Rotary Cutters Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

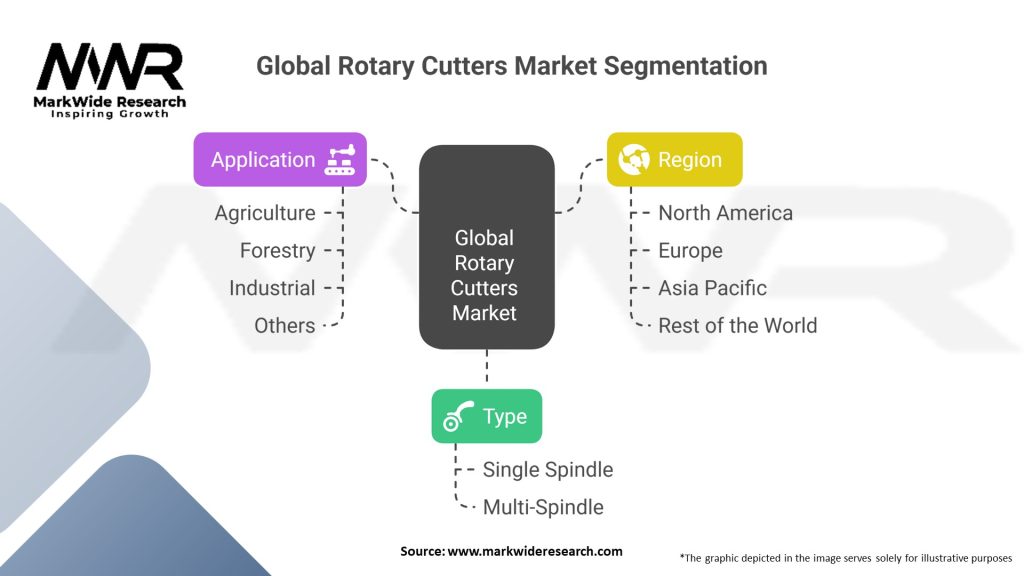

Segmentation:

The rotary cutters market can be segmented based on product type, application, end-use industry, and geography. Product types may include rotary mowers, flail mowers, boom mowers, and others. Applications can range from agriculture and forestry to landscaping and industrial use. End-use industries encompass agriculture, construction, and municipal sectors, among others.

Category-wise Insights:

Key Benefits for Industry Participants and Stakeholders:

SWOT Analysis:

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends:

Covid-19 Impact:

The global rotary cutters market was impacted by the COVID-19 pandemic, primarily due to disruptions in the global supply chain and temporary shutdowns of manufacturing facilities. However, the market showed resilience as the agriculture sector was deemed essential and continued operations. The pandemic also highlighted the importance of mechanized equipment in maintaining social distancing and reducing labor-intensive tasks.

Key Industry Developments:

Schneider Knife Co. introduced AutoBlade™ in 2023, an automated blade loader capable of hot-swapping tungsten-carbide blades without line stoppage.

MWI launched SmartCutter® sensor module in 2024, offering real-time blade-vibration analytics and remaining-life predictions via cloud dashboard.

Electron Energy secured partnership with Voith in 2022 to supply carbide blades for high-speed tissue slitting lines in Europe.

Nippon Carbide expanded DLC-coated blade production in 2023 by opening a new coating facility in Thailand, reducing lead times for Asia Pacific converters.

Analyst Suggestions:

Future Outlook:

The global rotary cutters market is projected to experience steady growth in the coming years. Factors such as increasing agricultural activities, rising focus on precision farming, and the need for efficient vegetation management in diverse sectors will drive market expansion. Technological advancements, including the integration of automation and GPS technologies, will further enhance the performance and capabilities of rotary cutters. Emerging economies are expected to offer lucrative opportunities, while sustainability and eco-friendly solutions will shape the future of the industry.

Conclusion:

The global rotary cutters market presents immense potential for growth and innovation. These versatile machines play a vital role in various industries, offering efficient solutions for land clearing, vegetation management, and landscaping tasks. Manufacturers should prioritize product development, strategic partnerships, and sustainable practices to meet market demands and capitalize on emerging opportunities. With advancements in technology and the increasing adoption of precision farming, the rotary cutters market is poised for a bright future.

What are rotary cutters in the context of the Global Rotary Cutters Market?

Rotary cutters are tools used for cutting various materials, including fabric, paper, and leather, featuring a circular blade that rotates to provide a clean cut. They are widely utilized in industries such as textiles, crafts, and manufacturing.

Which companies are leading the Global Rotary Cutters Market?

Leading companies in the Global Rotary Cutters Market include Olfa Corporation, Fiskars Group, and Westcott, among others. These companies are known for their innovative designs and high-quality cutting tools.

What are the key drivers of growth in the Global Rotary Cutters Market?

The growth of the Global Rotary Cutters Market is driven by the increasing demand for precision cutting tools in the textile and craft industries, as well as the rising popularity of DIY projects among consumers. Additionally, advancements in blade technology enhance cutting efficiency.

What challenges does the Global Rotary Cutters Market face?

The Global Rotary Cutters Market faces challenges such as the availability of alternative cutting tools and the potential for safety concerns associated with sharp blades. Moreover, fluctuations in raw material prices can impact production costs.

What opportunities exist in the Global Rotary Cutters Market for future growth?

Opportunities in the Global Rotary Cutters Market include the expansion of e-commerce platforms for tool sales and the introduction of eco-friendly materials in cutter production. Additionally, the growing interest in crafting and sewing presents a significant market potential.

What trends are currently shaping the Global Rotary Cutters Market?

Current trends in the Global Rotary Cutters Market include the development of ergonomic designs for user comfort and the integration of safety features in cutter designs. Furthermore, there is a rising trend towards sustainable manufacturing practices in the industry.

Global Rotary Cutters Market

| Segmentation | Details |

|---|---|

| Type | Single Spindle, Multi-Spindle |

| Application | Agriculture, Forestry, Industrial, Others |

| Region | North America, Europe, Asia Pacific, Rest of the World |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Global Rotary Cutters Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at