444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

The wraparound case packers market is a rapidly growing sector within the packaging industry. These machines are widely used in various industries, including food and beverages, pharmaceuticals, personal care, and logistics. Wraparound case packers offer efficient and automated packaging solutions, ensuring the safe transportation and storage of products. This comprehensive market analysis delves into the key insights, trends, opportunities, and challenges shaping the wraparound case packers market.

Wraparound case packers are advanced packaging machines designed to form and pack products into carton cases. They utilize a folding mechanism to wrap the case around the products, providing a secure and protective packaging solution. These machines offer high-speed packaging capabilities, accuracy in product placement, and customization options, making them indispensable in various industries.

Executive Summary

The wraparound case packers market is witnessing significant growth due to the rising demand for efficient packaging solutions, especially in industries dealing with high volumes of products. The increasing need for automation, cost-effective packaging, and improved operational efficiency are driving the market’s expansion. Key market players are focusing on technological advancements, product innovation, and strategic collaborations to gain a competitive edge.

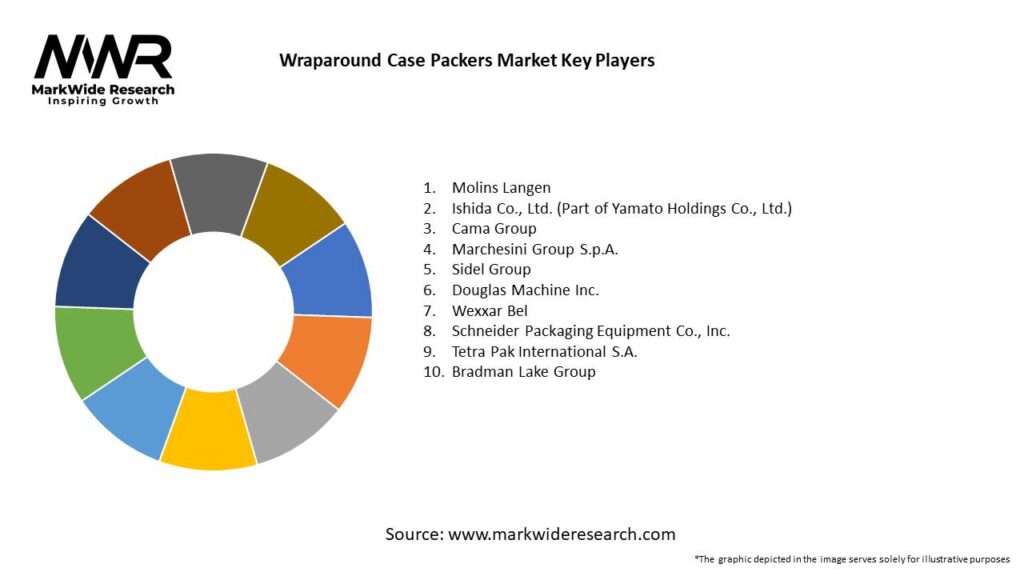

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Automation Trend: Manufacturers are shifting from manual and semi‑automatic case packers to fully automated wraparound solutions to meet labor constraints and quality requirements.

E‑commerce Growth: The boom in online retail has increased demand for small-lot, on‑demand packaging solutions that wraparound machines can handle efficiently.

Sustainability Focus: Reduced corrugated usage and lower adhesive consumption support corporate sustainability goals and regulatory compliance.

Modular Designs: Modular, retrofit-friendly packers enable end users to upgrade existing lines incrementally.

Aftermarket Services: Service contracts, remote troubleshooting, and parts availability are becoming key differentiators among suppliers.

Market Drivers

Labor Shortages: Rising labor costs and workforce shortages motivate manufacturers to automate repetitive packaging tasks.

Demand for Customization: Consumer preference for varied pack sizes and promotional runs fuels the need for quick-changeover machinery.

Operational Efficiency: High-speed wraparound packers reduce downtime, increase throughput, and lower total cost of ownership (TCO).

Regulatory Pressures: Packaging regulations emphasizing recyclability and waste reduction drive adoption of minimal‑waste case packers.

Technological Advancements: Integration of servo drives, robotic pick‑and‑place, and vision systems increases machine versatility and uptime.

Market Restraints

High Capital Investment: Significant upfront costs can deter smaller manufacturers from adopting fully automated wraparound machines.

Complex Maintenance: Advanced machinery requires skilled technicians and regular preventative maintenance to avoid unplanned stoppages.

Integration Challenges: Aligning new packers with legacy lines may require custom engineering and controls integration.

Energy Consumption: High-speed servo and pneumatic systems can lead to elevated energy usage if not optimized.

Supply Chain Disruptions: Fluctuations in corrugated board availability and chip shortages for electronic components can delay machine delivery.

Market Opportunities

SME Segment Growth: Development of cost‑effective, entry‑level wraparound packers tailored for small- and mid‑sized operations.

Pharma & Healthcare: Aseptic, tamper-evident wraparound cases for medical devices and pharmaceuticals.

Subscription Box Packaging: Rising popularity of subscription services opens new applications for varied case sizes and custom branding.

Service and Retrofit Business: Offering upgrades, remote diagnostics, and predictive maintenance as standalone services.

Green Packaging Solutions: Machines optimized for bio‑based board materials, recyclable adhesives, and minimal waste case formats.

Market Dynamics

Supply Side Factors: Innovations in machine design (e.g., quick tool‑less changeover, pre‑break creasing) and localized manufacturing to reduce lead times.

Demand Side Factors: End-user emphasis on flexibility, OEE (Overall Equipment Effectiveness), and lower TCO drives specification to multi-format machines.

Economic Factors: Post‑pandemic reshoring trends and incentives for automation investments; interest rates and CAPEX funding availability influence purchasing cycles.

Regional Analysis

North America:

Mature Market: High automation levels in beverage, food, and consumer goods industries.

Technological Leaders: US and Canada host major OEMs and early adopters of Industry 4.0.

Europe:

Sustainability Focus: EU regulations on packaging waste drive adoption of minimal-waste case packers.

Diverse Industries: Strong pharmaceutical and food processing sectors.

Asia‑Pacific:

Rapid Expansion: China, India, and Southeast Asia see growth in FMCG manufacturing and e‑commerce packaging.

Cost Sensitivity: Demand for affordable semi-automatic and entry‑level machines.

Latin America:

Infrastructure Development: Brazil and Mexico invest in packaging for domestic and export markets.

Labor Dynamics: Automation to address rising labor costs.

Middle East & Africa:

Emerging Opportunities: Demand in oil & gas, construction chemicals, and food & beverage.

Import Reliance: Heavy reliance on imported machines; potential for local servicing partners.

Competitive Landscape

Leading companies in the Wraparound Case Packers Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

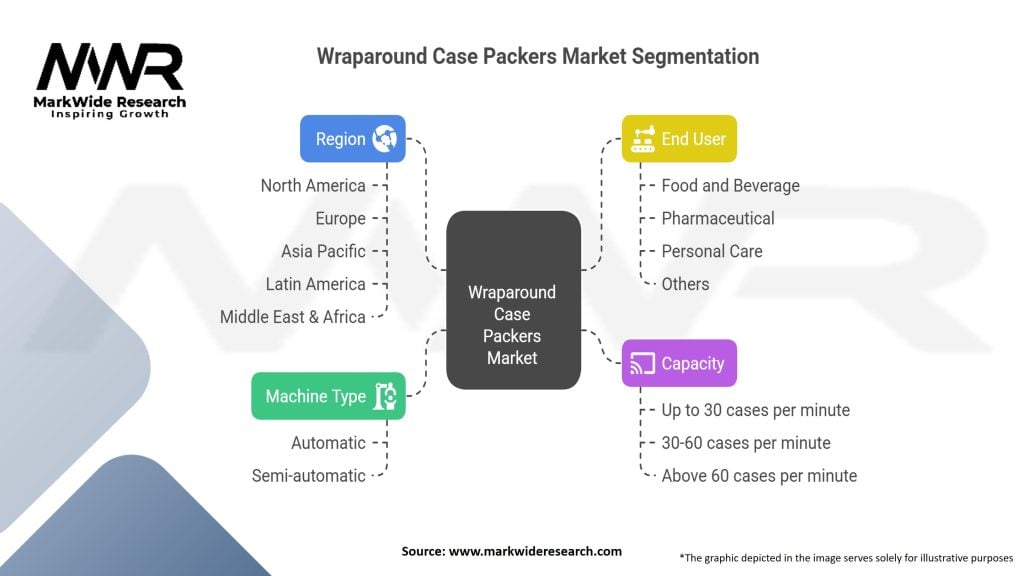

Segmentation

By Case Style:

RSC (Regular Slotted Case)

HSC (Half Slotted Container)

Custom Wraparound Trays

By Machine Type:

Semi‑Automatic

Fully Automatic

By End‑Use Industry:

Food & Beverage

Pharmaceuticals & Healthcare

Consumer Goods

Industrial & Electronics

E‑commerce & Fulfillment

By Automation Level:

Standalone Packer

Integrated Line (with feeder, erector, sealer)

By Region:

North America

Europe

Asia‑Pacific

Latin America

Middle East & Africa

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

Industry participants and stakeholders in the wraparound case packers market can benefit from various aspects, including:

SWOT Analysis

Strengths:

Versatility: Wide case size range and material compatibility.

Efficiency: Rapid changeovers and high line speeds.

Integration: Seamless with upstream/downstream automations.

Weaknesses:

High CAPEX: Cost barrier for SMEs.

Complexity: Requires skilled operators and maintenance teams.

Footprint: Fully automated lines demand significant floor space.

Opportunities:

SME Market Penetration: Develop rental/lease models and smaller machines.

Digital Services: Expand remote monitoring, predictive maintenance offerings.

Emerging Markets: Local service/support in APAC, LATAM, MEA.

Threats:

Economic Slowdowns: CAPEX cuts can delay purchases.

Raw Material Price Volatility: Corrugated board cost spikes impact ROI.

Competitive Alternatives: Stretch wrap, shrink wrap, and flexible packaging innovations.

Market Key Trends

Covid-19 Impact

The COVID-19 pandemic has significantly impacted the packaging industry, including the wraparound case packers market. While the initial phase witnessed disruptions in the supply chain and reduced production activities, the market has shown resilience and adaptability. The pandemic has accelerated the adoption of automation and contactless packaging solutions to ensure safe and hygienic processes.

Key Industry Developments

The wraparound case packers market has witnessed notable industry developments in recent years, including:

Analyst Suggestions

Based on the market analysis, analysts suggest the following strategies for industry participants and stakeholders:

Future Outlook

The future of the wraparound case packers market looks promising, with sustained growth anticipated. Advancements in automation, robotics, and intelligent packaging technologies will continue to shape the market landscape. The demand for efficient, cost-effective, and eco-friendly packaging solutions will drive the adoption of wraparound case packers across various industries.

Conclusion

The wraparound case packers market is witnessing steady growth driven by factors such as increasing demand for efficient packaging solutions, automation, and cost-effectiveness. With the emergence of new technologies and customization options, the market presents abundant opportunities for industry participants and stakeholders. By staying abreast of market trends, leveraging strategic partnerships, and focusing on innovation, businesses can thrive in this dynamic and evolving market.

Wraparound Case Packers Market

| Segmentation | Details |

|---|---|

| Machine Type | Automatic, Semi-automatic |

| Capacity | Up to 30 cases per minute, 30-60 cases per minute, Above 60 cases per minute |

| End User | Food and Beverage, Pharmaceutical, Personal Care, Others |

| Region | North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the Wraparound Case Packers Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at