444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2750

3D printing, also known as additive manufacturing, has emerged as a game-changer in the manufacturing industry. Latin America, with its growing industrial sector, has witnessed significant advancements in industrial 3D printing technology. This comprehensive report provides insights into the Latin America Industrial 3D Printing Market, highlighting its meaning, key market insights, drivers, restraints, opportunities, market dynamics, regional analysis, competitive landscape, segmentation, category-wise insights, key benefits for industry participants and stakeholders, SWOT analysis, market key trends, COVID-19 impact, key industry developments, analyst suggestions, future outlook, and a concluding perspective.

The Latin America Industrial 3D Printing Market refers to the utilization of additive manufacturing technology for producing functional and complex parts within industrial settings. This innovative process involves the layer-by-layer deposition of materials, such as polymers, metals, and ceramics, based on 3D digital models. It enables the production of customized, lightweight, and intricate components with enhanced precision, efficiency, and cost-effectiveness.

Executive Summary

The Latin America Industrial 3D Printing Market is projected to reach approximately USD 1.5 billion by 2030, growing at a compound annual growth rate (CAGR) of 20% from 2024 to 2030. Key drivers include rising investments in additive manufacturing technologies, increased applications in diverse sectors, and the growing need for customized solutions. Challenges such as high initial costs and limited awareness among smaller manufacturers may hinder market growth. However, opportunities in research and development, along with technological advancements, present significant growth potential.

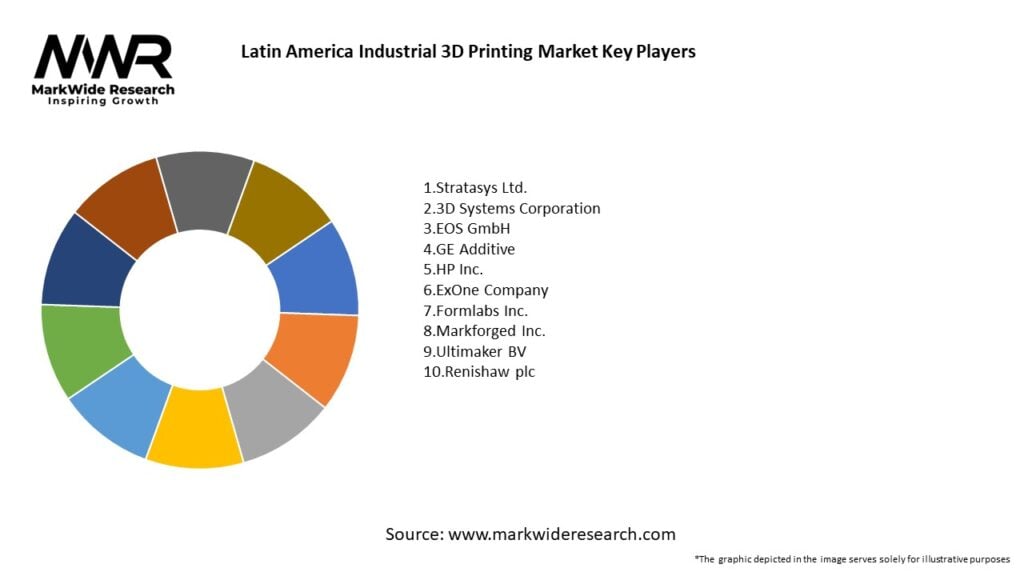

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

The key market insights section delves into the crucial factors driving the Latin America Industrial 3D Printing Market’s growth, including the increasing adoption of 3D printing in various industries, such as aerospace, automotive, healthcare, and consumer goods. It also highlights the market restraints, such as high initial setup costs and limited material options, and explores the opportunities emerging in the market.

Market Drivers

The market drivers section elaborates on the factors propelling the growth of the Latin America Industrial 3D Printing Market. These include:

Market Restraints

The market restraints section sheds light on the challenges hindering the growth of the Latin America Industrial 3D Printing Market. These include:

Market Opportunities

The market opportunities section explores the untapped potential in the Latin America Industrial 3D Printing Market. These opportunities arise from:

Market Dynamics

The dynamics of the Latin America Industrial 3D Printing Market include:

Regional Analysis

The Latin America Industrial 3D Printing Market exhibits varying trends across different countries:

Competitive Landscape

Leading companies in the Latin America Industrial 3D Printing Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The Latin America Industrial 3D Printing Market can be segmented based on various criteria to provide a detailed understanding of its structure and dynamics:

Category-wise Insights

Each category within the Latin America Industrial 3D Printing Market offers unique features and benefits tailored to different user needs:

Key Benefits for Industry Participants and Stakeholders

The Latin America Industrial 3D Printing Market offers several benefits for manufacturers, end-users, and consumers:

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Several key trends are shaping the Latin America Industrial 3D Printing Market:

Covid-19 Impact

The Covid-19 pandemic has significantly impacted the Latin America Industrial 3D Printing Market:

Key Industry Developments

The Latin America Industrial 3D Printing Market has seen several notable developments:

Analyst Suggestions

Based on market trends and developments, analysts suggest the following strategies for industry participants:

Future Outlook

The future outlook for the Latin America Industrial 3D Printing Market is highly promising, with sustained growth anticipated in the coming years. As industries continue to embrace additive manufacturing, the market is projected to reach approximately USD 1.5 billion by 2030, growing at a CAGR of 20% from 2024 to 2030.

Key trends shaping the future of the market include:

Despite challenges, companies that prioritize innovation, sustainability, and customer engagement will be well-positioned to thrive in the evolving Latin America Industrial 3D Printing Market.

Conclusion

The Latin America Industrial 3D Printing Market is on the brink of transformative growth, driven by technological advancements and increasing demand for customization and sustainability. As industries adapt to the changing landscape, 3D printing will play a critical role in shaping the future of manufacturing. Stakeholders who invest in innovation and strategic partnerships will capitalize on emerging opportunities in this dynamic market.

In conclusion, the Latin America Industrial 3D Printing Market presents significant growth opportunities fueled by technological advancements, increasing demand for complex components, and evolving industry requirements. By leveraging the benefits of 3D printing and addressing the associated challenges, businesses can revolutionize their manufacturing processes and stay ahead in the competitive market landscape.

What is the Latin America Industrial 3D Printing?

Latin America Industrial 3D Printing refers to the use of additive manufacturing technologies in various industrial applications across the region, including prototyping, tooling, and production of complex parts in sectors like aerospace, automotive, and healthcare.

Who are the key players in the Latin America Industrial 3D Printing market?

Key players in the Latin America Industrial 3D Printing market include Stratasys, 3D Systems, EOS, and HP, among others.

What are the main drivers of growth in the Latin America Industrial 3D Printing market?

The main drivers of growth in the Latin America Industrial 3D Printing market include the increasing demand for customized products, advancements in 3D printing technologies, and the need for cost-effective manufacturing solutions.

What challenges does the Latin America Industrial 3D Printing market face?

Challenges in the Latin America Industrial 3D Printing market include high initial investment costs, limited awareness of technology benefits, and regulatory hurdles that can impede adoption.

What opportunities exist in the Latin America Industrial 3D Printing market?

Opportunities in the Latin America Industrial 3D Printing market include the potential for innovation in materials and processes, growth in the aerospace and automotive sectors, and increasing government support for advanced manufacturing technologies.

What trends are shaping the Latin America Industrial 3D Printing market?

Trends shaping the Latin America Industrial 3D Printing market include the rise of sustainable materials, integration of artificial intelligence in design processes, and the expansion of on-demand manufacturing capabilities.

Latin America Industrial 3D Printing Market

| Segmentation Details | Description |

|---|---|

| By Component | Hardware, Software, Services |

| By Technology | Stereolithography (SLA), Selective Laser Sintering (SLS), Others |

| By Application | Prototyping, Tooling, Functional Parts, Others |

| By End-User | Automotive, Aerospace & Defense, Healthcare, Others |

| By Country | Brazil, Mexico, Argentina, Others |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the Latin America Industrial 3D Printing Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at